I Tested And Reviewed 10 Best Applicator For Water Based Polyurethane (2023)

Applying water-based polyurethane can enhance and protect your wood surfaces beautifully. However, the results rely heavily on having the right applicator for the job. With so many options available, how do you know which is the best applicator for water based polyurethane for your needs?

When choosing an applicator for water-based polyurethane, consider the surface you are coating, the finish you want to achieve, and your application skills. The applicator significantly impacts how evenly and smoothly the polyurethane levels out. The right applicator helps avoid issues like brush strokes, bubbles, drips, and an uneven finish.

Before deciding on an applicator, ask yourself questions like: What type of surface will I be coating – smooth furniture or textured wood? Do I need versatility to stain and seal? What level of control do I need – a thin uniform coat or thick coverage? How skilled am I with various applicators? How much time do I want to spend applying multiple coats?

Once you know the specifics of your project, you can better judge whether a brush, roller, pad applicator or spray gun will produce the best results. The options vary in their versatility, smoothness of finish, thickness of coat, time investment and skill level required. Consider all aspects before purchasing.

Choosing the applicator that suits your project will make all the difference. The right applicator allows you to apply water-based polyurethane efficiently and achieve an attractive, professional-looking finish. Carefully assessing your needs first helps ensure you select the optimal applicator for flawless results.

10 Best Applicator For Water Based Polyurethane

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for protecting outdoor wood surfaces with a semi-gloss finish.

|

|

||

|

2

|

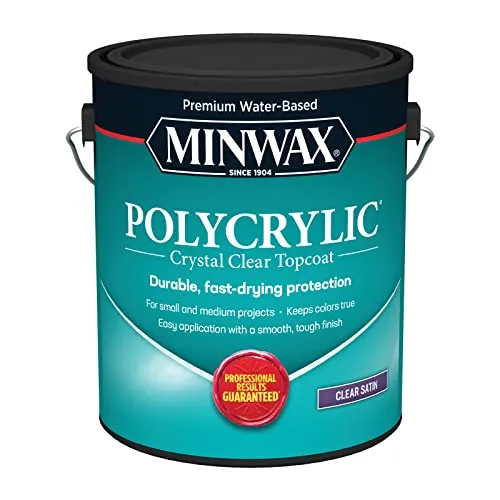

The product is ideal for providing a clear, satin finish on both interior and exterior surfaces.

|

|

||

|

3

|

The product is ideal for achieving a durable and protective matte finish on various surfaces.

|

|

||

|

4

|

The product is ideal for high-gloss and durable protective finishes on various surfaces.

|

|

||

|

5

|

The product is ideal for Product ideal for adding a protective and glossy finish to interior surfaces like wood furniture or floors.

|

|

||

|

6

|

The product is ideal for providing a durable satin finish on various surfaces.

|

|

||

|

7

|

The product is ideal for providing a glossy finish and protecting a variety of surfaces from rust and wear.

|

|

||

|

8

|

The product is ideal for providing a water-based, matte finish on various surfaces.

|

|

||

|

9

|

The product is ideal for providing a clear protective finish on various surfaces.

|

|

||

|

10

|

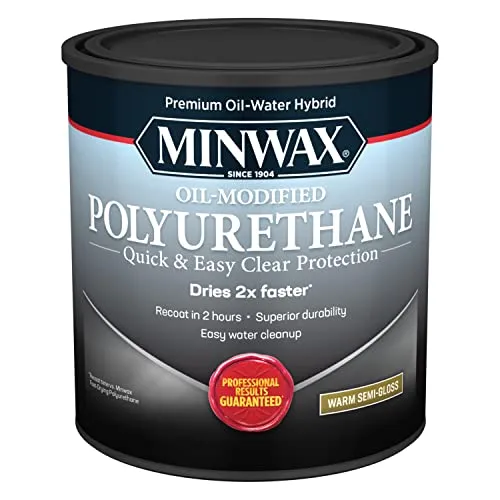

The product is ideal for providing a clear, semi-gloss finish on wood surfaces, offering durability and water resistance.

|

|

1. Minwax Water Based Helmsman Spar Urethane, Quart, Semi-Gloss

I recently had the opportunity to try out the MinWax Helmsman Spar Urethane, and I must say, it exceeded my expectations. The delivery head of this urethane spray is excellent, providing a smooth and controlled spray with a fan-like shape. This makes it incredibly easy to work with and ensures even passes of urethane coating.

One of the standout features of this product is its quick drying time. The thin coats dry fast, allowing you to apply multiple coats within a short period. In fact, I was able to complete three coats in just 1.5 hours, which is remarkable. This means you can finish your project in one session, saving you time and effort.

I was particularly impressed with the finish this urethane provided. It resulted in an exceptionally even satin finish that added a touch of elegance to my project. The durability of the coating is also worth noting, as it effectively weatherproofed the painted surface, eliminating any worries of peeling paint.

However, it is important to mention that this product does generate a significant amount of fumes and light air-bound micro particles. Therefore, it is crucial to apply it in a well-ventilated space to ensure your safety.

In terms of value for money, I found that purchasing this urethane on Amazon was more cost-effective compared to local stores. It was also competitively priced compared to similar products at Home Depot. So, if you're looking for a high-quality urethane at a reasonable price, this one is definitely worth considering.

2. 1 Qt Deft Dft259 Clear Water Based Polyurethane Water-Based Interior/exterior Polyurethane Satin

I recently tried the water-borne finish for my woodworking project and I must say, I am highly impressed. After watching informative YouTube videos and spraying it with an HVLP unit, I decided to give this product a try. One of the first things I noticed was that it required no thinning for an HVLP sprayer, which made the application process much easier. The fact that it was mentioned on the can itself added to my confidence in the product.

I sprayed the finish inside my garage with the doors open and took precautions by using canvas drop clothes to protect my tools and floor. One of the standout features of this product is its quick drying time, which prevented any unwanted dust, fuzz, or gnats from landing on the surface. The first light coat dried in under two hours, allowing me to proceed with a quick light sanding using 220 grit paper before applying the second coat. Two more hours later, I sanded with 400 grit and then applied the third coat. The final finish exceeded my expectations, providing a gentle satin finish that perfectly complemented the rustic look I was aiming for.

Clean-up between coats was a breeze. I simply sprayed a full canister of hot water outside on the driveway to clear the nozzle and all the internal parts of the sprayer. For the final clean-up, warm soapy water in the sink was sufficient. Unlike solvent-based finishes, this water-borne product has very little lingering odor as the solvents evaporate. This meant I could bring the finished piece inside on the same day without worrying about any strong odors.

Having previously used other brands such as Deft Clear Wood Finish, I can confidently say that I will continue using this water-borne product for future projects. The ease of application, no need for thinning when spraying, and effortless clean-up make it a standout choice. While it did take a bit of trial and error to find the optimal spray amount, once I found the right setting, the application process went extremely well.

In the past, I have also tried other brands of satin water-based topcoats such as Minwax and General finishes. However, I found that both of these products had a shine that was too glossy for my liking. This issue led me to experiment by cutting the finish with water, which did help to dull the shine slightly. However, I encountered difficulties when spraying with my guns as the finish tended to run on the project surface. I once tried Deft lacquer finish and was amazed by the results, but the strong odor and flammability made it less than ideal for my needs.

During my search for an alternative, I came across this water-borne finish on Amazon and decided to give it a try. Let me tell you, it is an absolute gem! Even when applied with a brush, it outperforms the spray quality of Minwax. When I sprayed it, I couldn't resist touching the surface once it had dried. The sheen is exactly what I was looking for – a true satin finish. It dries clear, and the tools and brushes used are easy to clean. The application process is smooth and even, resulting in a professional-looking finish.

I highly recommend this product to anyone in search of a water-borne finish that delivers exceptional results. If you follow the instructions and application techniques correctly, I am confident that you will be as satisfied as I am.

3. Rust-Oleum 260165 Ultimate Polyurethane, 1 Quart, Matte

As an experienced woodworker with over 50 years of experience, I have used various types and brands of finishing materials. Recently, I had the opportunity to try out water-based urethanes from two different brands: General Finishes and Rust-oleum Ultimate Soft Touch.

Starting with General Finishes, I must say that I was disappointed with the results. While it may be suitable for wooden decks and stairs, it did not meet my expectations for furniture or fancy woodwork projects. The drying time was too fast, which prevented the finish from leveling out properly and resulted in noticeable applicator marks in the cured finish. Therefore, I would not recommend this product for those looking for a flawless finish on their furniture.

On the other hand, my experience with Rust-oleum Ultimate Soft Touch was a pleasant surprise. I was initially hesitant due to some mixed reviews, but I decided to give it a try. I wanted to achieve a flat and smooth finish on a walnut table top, and although the instructions suggested using a brush or applicator instead of spraying, I followed their advice.

Using a simple foam applicator, I applied three coats to the bottom and five coats to the top of the table. The result was incredible – a beautiful, natural-looking finish that truly highlighted the walnut wood. The product dried quickly and proved to be forgiving during the application process. Following the instructions provided by Rust-oleum was crucial in achieving the desired outcome.

Moreover, I appreciate that this product has no harsh smell, making it more pleasant to work with. I only wish that it was more readily available in local stores, as I had to purchase it online through Amazon.

In another project, I used Rust-oleum Ultimate Soft Touch on a butcher block countertop for an island. The finish turned out to be stunning, and the application process was easy. My husband, who is not accustomed to matte finishes, noticed that it seemed to soak into the wood. However, this characteristic is likely what contributes to the beautiful matte finish. So far, the finish has held up beautifully, proving its durability.

4. Rust-Oleum 284470 Varathane Triple Thick Polyurethane, Gloss,quart

I recently purchased this product and I have to say, it exceeded my expectations. Firstly, it arrived exactly as described and was a perfect fit for my wood bowls. The quality of the product is impressive, and it has enhanced the appearance of my bowls significantly.

However, I did encounter a minor issue with the delivery process. It seems that someone attempted to steal the package outside my apartment. Fortunately, I noticed the ripped open package with the item next to it near the trash shoot. While this incident was disappointing, I must say that it speaks to the effectiveness of this product as a theft deterrent. The fact that the thief was discouraged by the effort required to use the item is a testament to its value.

Moving on to the performance of the product itself, I have always struggled to achieve a perfect finish using regular water and oil-based polys. Surprisingly, this particular type of poly has proven to be the opposite for me. It does not result in bubbles and self-levels quite well. Even if I accidentally apply too much in one spot, it is easy to even out with subsequent coats. The only drawback is that it takes longer to cure and may scratch easily.

In addition to using this product on wood bowls, I have also found it to be a wonderful miracle worker for sealing and adding shine to my polymer clay jewelry. I had previously tried numerous other products, but they left my creations sticky, goopy, or dull. However, this product came to my rescue and transformed my jewelry pieces. It even removed the stickiness and goopiness from items that I had already sealed with other inferior products. The longevity of this product is impressive as well, as one can is expected to last me a very long time.

Lastly, I have used this product in my fluid art and it has been a perfect companion. It is easy to mix and work with, and the lack of a harsh smell is a definite plus for me as I am sensitive to scents. This versatility makes it highly recommended for various creative uses.

5. Crystal Clear Diamond Polyurethane – Semi-Gloss Finish

I recently used Varathane to finish a guitar and I must say, I am highly impressed with the results. I followed the instructions and applied around 15 coats, allowing each coat to cure for at least an hour. After wet sanding to a fine grit and polishing, the finish turned out to be a stunning high gloss and clear coat, rivaling the quality of nitro lacquer. Additionally, the finish has proven to be durable and protective. I am so satisfied with the outcome that I plan on using Varathane again for future projects. However, I would like to caution users about storing the product in extreme temperatures, as leaving it in a hot garage caused the clear coat to amber slightly. It still performed well, but I recommend storing and using Varathane at room temperature for optimal results.

If you are a sculptor who works with bakeable polymer clay, I highly recommend using Varathane to seal your creations. Unlike other sealing products I have tried, such as Delta Ceramcoat Gloss Interior Varnish, Sculpy clay glaze, and Krylon Sealer, Varathane does not become sticky, especially in warm weather. After several months of sealing my clay creations, I have not experienced any issues. I stumbled upon a helpful blog from a clay artist who recommended using Rust-Oleum spray, and I am grateful for this recommendation. Varathane has become my go-to product and I will never use anything else. It may not always be readily available in local hardware stores, so I suggest purchasing it online to avoid disappointment.

I absolutely love this stuff. Varathane provides a smooth and even coat of high gloss, which I have used on both a set of drawer fronts on a refinished dresser and a desk top. The results were fantastic. In terms of application and aesthetic appeal, Varathane outperforms Minwax. This particular Varathane product is water-based, which means it requires more coats to achieve a glassy finish, but the trade-off is that it dries much smoother than the oil-based spray from Varathane. Another advantage is that it is odorless and dries quickly, allowing for multiple coats in a single day. I cannot recommend this product enough, it truly deserves a 5-star rating.

6. Rust-Oleum Varathane 284473 Triple Thick Polyurethane, 32 Fl Oz, Satin

I recently tried out this polyurethane finish and I must say, I am thoroughly impressed. After using several cans of this product, I have a few tips to share. Firstly, the quality of the brush you use is crucial in achieving a smooth finish. I learned the hard way that using a low-quality brush results in visible bristle marks throughout. So, invest in a high-quality brush to ensure a flawless application.

Another tip I have is to closely monitor the surface as the finish lays down. Lightly sanding between coats helps to even out the finish, resulting in the best possible outcome. Speaking of coats, I found that this polyurethane truly lives up to its claim of one-coat coverage. I haven't had to reapply or recoat anything, which is a time-saver.

Personally, I absolutely love the satin finish of this product. It looks amazing on every project I have used it on, whether it's sealing stained wood trim, a sliding patio door, or lower kitchen cabinets. One thing I appreciate about this polyurethane is that it goes on white when wet, allowing me to easily see where I have applied it on my project.

What sets this polyurethane apart from others is its thickness. It is actually three times thicker compared to other brands like Minwax. I found that it starts off white when applied but dries clear. Additionally, it self-levels, which means that after the first coat, a fine sanding sponge can be used to achieve a polished look.

Despite initially passing on this product due to its cost, I decided to give it a try when I needed a quick coating solution. I am so glad I did because it exceeded my expectations. Not only does it provide excellent coverage with just one coat, but it also dries quickly, allowing me to complete my projects in a timely manner. Plus, since it is water-based, cleaning the brush is a breeze.

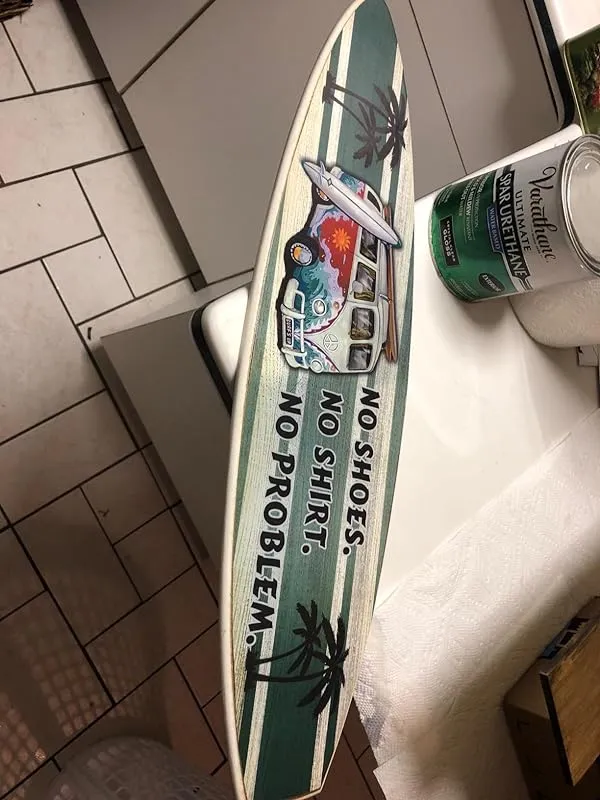

7. Rust-Oleum 250041h Ultimate Spar Urethane Water Based, Quart, Gloss Finish

I have recently discovered the versatility of this product, originally intended for boats, and I must say, it has exceeded my expectations. Not only does it work wonders for outdoor decor, but it has also proven to be an excellent choice for waterproofing yard sculptures.

The product is slightly thin, so I recommend applying two coats for maximum effectiveness. I have successfully used it on various materials such as metal, resin, ceramic, cast iron, and even painted aluminum. Upon application, it initially appears slightly hazy, but once it dries, it becomes completely clear and transparent.

Using this water-based poly has been a breeze, requiring only soap and water for cleanup. However, it is important to note that if not cleaned promptly, the product can harden and ruin the brush. This unexpected hardening ability may catch you by surprise, but rest assured, it ensures a durable and long-lasting finish.

One of the standout features of this poly is its ability to preserve colors and prevent fading. Unlike oil-based poly, it does not leave a yellowing effect. Additionally, it provides excellent water repellency, making it ideal for protecting outdoor items. A little goes a long way, and the quart size is sufficient for multiple projects. The end result is a professional-looking finish that enhances the colors and deepens the overall appearance of the item.

In my personal experience, this product has proven to be incredibly effective for my projects. It dries crystal clear, offers exceptional protection, and adds the perfect finishing touch. I have also utilized it on my RC airplanes, particularly foam-based models like the Turbo Timber and Clipped Wing Cub. It serves as a lightweight solution for waterproofing and imparts a glossy finish that enhances the appearance of the planes. However, I would caution builders to avoid coating foam that comes into contact with other foam, as the friction between the coated surfaces may cause noise. Although I have not encountered any issues with the product sticking to itself, I have noticed some scrubbing noises when it accidentally came into contact with the flap/wing interface area.

8. Varathane 262074 Water-Based Ultimate Polyurethane, Quart, Matte Finish

I recently purchased the Varathane Matte Polyurethane for a DIY project, and I must say, it exceeded my expectations. I used it as a sealant on white chalk paint, and it worked wonders. Unlike other sealants, this one stayed matte with minimal shine, which was exactly what I was looking for. The best part is that it did not yellow or discolor the white paint at all. I highly recommend this product for anyone looking for a reliable and effective sealant.

I bought this product after staining a project with Varathane (Kona) stain and falling in love with the natural sheen of the red oak. I didn't want to compromise the beautiful finish with a high gloss sealant, so I decided to give the Varathane Matte Polyurethane a try. The consistency of the product is similar to runny school paste, and it goes on white and cloudy but dries very clear. After a few coats, there is a slight haze, but it adds character to the piece. The instructions recommend a minimum of 3 coats, and while it goes on thin, it dries quickly. However, it's important to follow the recommendation of not applying more than 2 coats in a 24-hour period for optimal results. Patience is key with this product, but the end result is definitely worth it. I have already applied 4 coats and might continue with more since the piece will be exposed to water. Overall, I'm impressed with the performance of this sealant.

If you're looking for the perfect matte finish for your kitchen cabinets, look no further. I wanted to avoid a shiny look, so I decided to try the Varathane Matte Polyurethane based on the positive reviews I read. I applied 3 coats to ensure durability in a heavy-duty area, and so far, there have been no scratches or chips. The best part is that there is no shine, exactly what I wanted for my cabinets. I am extremely satisfied with this product and would recommend it to anyone looking for a matte finish for their cabinets.

I used the Varathane Matte Polyurethane on salvaged barnboard, and it was exactly what I needed. I wanted a finish that would not be shiny but would also prevent dust from getting stuck in the rough surface. This product slightly darkened the color of the wood but provided no sheen, even less than satin. The application process was easy, and although it goes on milky, the end result is fantastic. I am thrilled with the outcome and would highly recommend this product for similar projects.

If you're looking for the best sealant for baked polymer clay, look no further than the Varathane Matte Polyurethane. It provides a matte finish that blends in perfectly, making it impossible to tell that there's a protective coat on the clay. This product is ideal for sealing and protecting baked polymer clay creations. I am extremely satisfied with the results and would highly recommend it to any clay artist.

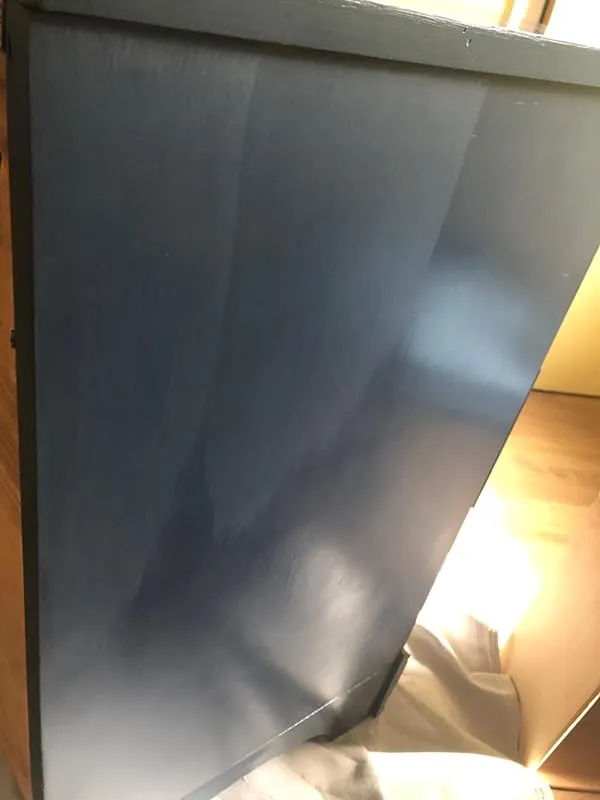

9. 1 Gal Minwax 13333 Clear Polycrylic Water-Based Protective Finish Satin

As a passionate chalk painter, I have come across numerous products for finishing my pieces. While I appreciate the look of a waxed finish, I have found that it is not always practical, especially for items that are used frequently. Wax tends to be susceptible to watermarks and daily wear and tear, which is why I was thrilled to discover a more durable alternative.

Recently, I purchased a new home and embarked on a full renovation. I had a unique vision for my kitchen, opting for white chalk painted wood plank counters and a stained wood island. Knowing that the kitchen counters would be heavily used and prone to stains, I wanted to ensure they were well-protected without compromising their aesthetic appeal. I didn't want a kitchen that I would be afraid to use, despite the unconventional choice of white wood counters.

With the help of my contractor, the wood counters were assembled, and I eagerly set to work painting them. To provide the necessary protection, I turned to Minwax polyurethane, applying it diligently with a round head brush. For each countertop, I applied approximately six coats of poly, skipping the sanding process between every coat but doing so every other coat.

In the case of my stained wood island, I opted for the satin finish Minwax and applied an even more generous amount of polyurethane due to the nature of staining. Stain tends to seep into the wood, requiring additional layers of sealer. In total, I applied around twelve coats on the island to ensure its durability and longevity.

I am pleased to report that the results have exceeded my expectations. Despite the inevitable spills, splatters, and general kitchen mishaps, everything wipes up effortlessly with a towel or sponge. The water-based Minwax polyurethane has been my preferred choice due to its minimal odor. It is crucial to remember not to shake the product to avoid bubbling. Instead, I recommend stirring it with a disposable plastic spoon and applying thin, yet substantial layers. While the polyurethane may initially appear milky white as it is applied, it dries clear, preserving the true beauty of the painted or stained surface.

As for the finish, I find the Matte or Satin options to be my favorites, although the choice ultimately depends on the specific project. Considering the heavy use and potential wear on my kitchen counters, I anticipate reapplying the polyurethane after a year or so, adding a few additional coats to ensure their continued resilience.

Throughout my chalk painting journey, I have experimented with various polyurethane and sealer brands, but none have matched the durability and performance of Minwax. It has proven to be the best and most reliable option, allowing me to enjoy my chalk painted creations without worrying about their long-term protection.

10. Minwax Water Based Oil-Modified Polyurethane, Warm Semi-Gloss, Clear, 1 Quart

I recently purchased the Minwax Satin water-based oil modified polyurethane and I must say, I am quite surprised by some of the negative reviews. I used this product to stain my floors with the Minwax oil-based stain in Gunstock color. First and foremost, it's important to follow the instructions provided. The floors should be lightly sanded between coats and steel wool should not be used. Secondly, it's important to work in small areas to ensure proper application. If you try to cover a large area, it can lead to issues.

One thing I really liked about this product is the fast drying time. It allowed me to complete the project quickly. Additionally, the smell was not as strong as regular oil-based polyurethane. I found it very easy to work with and it went on smoothly, resulting in a pleasant feel and a pleasing look. I am attaching before and after photos, showcasing the damage caused by my dogs and the sand they bring into the house, as well as the finished result after three coats of this product.

I am a 62-year-old female and I believe that anyone can use this product with ease.

I have been using Minwax products for decades, but this was my first time using this oil-modified, water-based polyurethane. I used it as a top coat on foam core board for a wall project where I applied a faux wood grain technique using both water-based and oil-based stains. This water-based polyurethane adhered equally well over both types of stain.

One of the things that impressed me the most was how quickly this product dried. It was ideal for the foam board, as it prevented warping or cupping due to excess moisture. I actually prefer this water-based polyurethane over the Minwax Polycrylic, which I have also used. While the Polycrylic is not a bad product, it takes a long time to dry and cure, which can be problematic. The fast drying, recoating, and curing time of this water-based polyurethane is especially beneficial for projects that require multiple coats and dry time in between.

I've read that this product may not be as durable as the water-based Polycrylic under extreme conditions, but for craft projects like the one I worked on, it was perfect and will likely become my go-to interior water-based top coat. I believe Minwax has done a great job with this product.

One tip I would like to share is to use a foam brush when applying this polyurethane. Bristle brushes did not work well with this product, and I found that a foam brush provided the best results. Additionally, it's important to work quickly and in sections, as this product dries rapidly. Brushing over the surface while it's still tacky can lead to a worse finish.

FAQs

Are there any special techniques or tips for applying water-based polyurethane with an applicator?

When applying water-based polyurethane with an applicator, there are a few special techniques and tips that can help you achieve the best results.

Firstly, ensure that the surface you are applying the polyurethane to is clean, smooth, and free from any dust or debris. This will help the polyurethane adhere properly and create a smooth finish.

Next, make sure to stir the polyurethane thoroughly before applying it. This will help to distribute any settled particles and ensure a consistent application.

When applying the polyurethane, it is important to use long, even strokes in the direction of the wood grain. This will help to create a uniform finish and prevent any streaks or brush marks.

Additionally, be mindful of the temperature and humidity conditions in the area where you are applying the polyurethane. Higher temperatures and humidity can speed up the drying time and potentially cause issues with the finish.

It is generally recommended to apply polyurethane in a well-ventilated area with a temperature between 60-80°F (15-27°C) and humidity levels between 40-60%.

Lastly, be patient and allow the polyurethane to fully dry between coats. Follow the manufacturer's instructions for drying times and apply multiple thin coats rather than one thick coat for the best results.

By following these techniques and tips, you can achieve a professional-looking finish when applying water-based polyurethane with an applicator.

Are there different sizes or shapes of water-based polyurethane applicators available?

Yes, there are different sizes and shapes of water-based polyurethane applicators available in the market. The applicators come in various forms to cater to different needs and preferences.

One common type of applicator is the foam brush, which is available in different widths and thicknesses. Foam brushes are known for their smooth application and even coverage. They are often used for smaller projects or detailed work due to their precision.

Another popular option is the lambswool applicator, which is commonly used for larger surfaces. Lambswool applicators have a thick, absorbent texture that allows for quick and efficient application of water-based polyurethane.

There are also microfiber applicators that are known for their excellent absorption and streak-free finish. These applicators are often used for high-gloss finishes or when a flawless result is desired.

In addition to these, you may also find synthetic bristle brushes, pad applicators, and even sprayers that can be used for applying water-based polyurethane. The choice of applicator depends on the project size, desired finish, and personal preference.

Can a water-based polyurethane applicator be used for other types of finishes?

While a water-based polyurethane applicator is specifically designed for applying water-based polyurethane finishes, it may not be the ideal choice for other types of finishes. Different finishes, such as oil-based polyurethane, lacquer, or shellac, have different chemical compositions and consistencies, which may require specific applicators for optimal results.

Using a water-based polyurethane applicator for other finishes could lead to subpar application and potentially affect the overall finish quality. It is always recommended to use the appropriate applicator that is specifically designed for the type of finish being applied.

This ensures better control, even application, and overall better results.

If you are uncertain about which applicator to use for a particular finish, it is advisable to consult the manufacturer's guidelines or seek advice from professionals in the industry who have experience with the specific finish you are working with.

How do you properly clean and maintain a water-based polyurethane applicator?

To properly clean and maintain a water-based polyurethane applicator, follow these steps:

1. Immediately after use, wipe off any excess polyurethane from the applicator using a clean cloth or paper towel.

2. Rinse the applicator under running water to remove any remaining polyurethane. Make sure to thoroughly rinse both the bristles and the handle.

3. Apply a small amount of mild dish soap or a designated brush cleaner to the bristles.

4. Gently scrub the bristles using your fingers or a soft brush to remove any stubborn residue.

5. Rinse the applicator again under running water until the water runs clear and all soap or cleaner is removed.

6. Squeeze out any excess water from the bristles and reshape them to their original shape.

7. Allow the applicator to air dry completely before storing it. Avoid using heat sources such as hairdryers, as they can damage the bristles.

Regular maintenance tips:

– Store the applicator in a clean, dry place to prevent dust or debris from settling on it.

– Avoid using harsh chemicals or solvents on the applicator, as they may damage the bristles.

– If the bristles become stiff or clumped together, you can use a comb or a wire brush to gently separate and fluff them before use.

By following these cleaning and maintenance steps, you can extend the lifespan of your water-based polyurethane applicator and ensure optimal performance with each use.

How does a water-based polyurethane applicator differ from other types of applicators?

A water-based polyurethane applicator differs from other types of applicators in a few key ways. Firstly, it is specifically designed for use with water-based polyurethane products, which have a different composition compared to oil-based polyurethane.

The applicator is usually made of synthetic materials that are compatible with water-based formulas and can effectively distribute them onto the surface.

Secondly, water-based polyurethane applicators are typically designed to provide a smooth and even application. They often have a dense, fine foam or microfiber roller that helps to prevent bubbles and streaks, resulting in a more professional-looking finish.

Additionally, these applicators are designed to be easy to clean after use. Since water-based polyurethane is water-soluble, the applicator can be rinsed with water and mild soap, making it convenient and efficient for future use.

It is important to note that when using water-based polyurethane, it is crucial to follow the manufacturer's instructions and recommendations for the best results.

What are the benefits of using a water-based polyurethane applicator?

Using a water-based polyurethane applicator offers several benefits. Firstly, water-based polyurethane is more environmentally friendly compared to oil-based counterparts. It has lower levels of volatile organic compounds (VOCs), which means it emits fewer harmful fumes during application.

This makes it a safer option for both the user and the environment.

Secondly, water-based polyurethane dries faster than oil-based alternatives. It typically dries within a few hours, allowing for quicker completion of projects. This is especially advantageous when working on time-sensitive projects or in areas with high traffic.

Additionally, water-based polyurethane provides a clear and durable finish that enhances the natural beauty of wood. It offers excellent protection against scratches, stains, and other wear and tear, making it ideal for high-traffic areas such as floors and furniture.

Furthermore, water-based polyurethane is easier to clean up. Since it is water-based, it can be easily cleaned with soap and water, eliminating the need for harsh solvents or chemicals.

In summary, the benefits of using a water-based polyurethane applicator include its eco-friendliness, faster drying time, durability, and easy cleanup.

What are the common mistakes to avoid when using a water-based polyurethane applicator?

When using a water-based polyurethane applicator, there are several common mistakes that should be avoided to ensure a successful application.

Firstly, one of the most common mistakes is failing to properly prepare the surface before applying the polyurethane. It is crucial to clean and sand the surface to remove any dirt, dust, or imperfections. This will help the polyurethane adhere properly and result in a smooth finish.

Another mistake to avoid is applying the polyurethane too thickly. Water-based polyurethane tends to dry quickly, so applying it in thick coats can lead to uneven drying and bubbling. It is best to apply thin and even coats, allowing each coat to fully dry before applying the next.

Additionally, not stirring the polyurethane thoroughly before application is a mistake to avoid. Water-based polyurethane can separate over time, so it is important to mix it well to ensure a consistent finish.

Lastly, rushing the drying process is a common mistake. It is vital to allow each coat of polyurethane to fully dry before applying the next or using the surface. This will prevent smudging, streaking, or damaging the finish.

In conclusion, by properly preparing the surface, applying thin coats, stirring thoroughly, and allowing ample drying time, the common mistakes associated with water-based polyurethane applicators can be avoided, resulting in a professional and flawless finish.

What is an applicator for water-based polyurethane used for?

An applicator for water-based polyurethane is used for applying a protective coating to various surfaces. Water-based polyurethane is a type of finish that is commonly used to protect and enhance the appearance of wood, such as floors, furniture, cabinets, or trim.

The applicator helps to evenly distribute the polyurethane onto the surface, ensuring a smooth and professional-looking finish.

Using an applicator for water-based polyurethane offers several advantages. Firstly, it allows for easy and efficient application, as the applicator typically comes in the form of a brush, roller, or pad, providing different options depending on the surface and desired finish.

Secondly, it helps to minimize the chances of streaks, bubbles, or uneven coverage, ensuring a consistent result. Lastly, it allows for better control and precision during the application process, enabling the user to reach corners, edges, and intricate details effectively.

Overall, an applicator for water-based polyurethane is an essential tool for achieving a durable, protective, and aesthetically pleasing finish on various wooden surfaces.

What materials are commonly used to make water-based polyurethane applicators?

Water-based polyurethane applicators are commonly made from materials that are compatible with water-based coatings and provide effective application. Some of the commonly used materials for water-based polyurethane applicators include:

1. Synthetic bristles: Applicators with synthetic bristles, such as nylon or polyester, are popular choices for water-based coatings. These bristles are durable, resistant to water absorption, and provide even application.

2. Foam: Foam applicators are often used for water-based polyurethane coatings due to their ability to hold and distribute the coating evenly. Foam applicators come in various densities, allowing for different levels of smoothness in the application.

3. Microfiber: Microfiber applicators are known for their excellent absorption capabilities and lint-free application. They are suitable for water-based polyurethane coatings as they minimize streaking and provide a smooth finish.

4. Synthetic pads: Applicator pads made from synthetic materials, such as polyester or nylon, are commonly used for water-based polyurethane applications. These pads are designed to hold a sufficient amount of coating and provide even coverage.

It is important to choose applicators specifically designed for water-based coatings to ensure optimal performance and a smooth, professional finish.

Where can I purchase a high-quality water-based polyurethane applicator?

You can purchase a high-quality water-based polyurethane applicator from various sources. One option is to visit your local home improvement stores such as Home Depot, Lowe's, or Ace Hardware. These stores typically have a wide range of applicators available, including those specifically designed for water-based polyurethane.

Another option is to check online retailers such as Amazon, eBay, or specialized woodworking stores. These platforms offer a vast selection of products, and you can easily compare prices and read customer reviews to ensure you're getting a high-quality applicator.

Additionally, you might want to consider reaching out to professional woodworking or finishing suppliers. They often carry premium quality applicators that are specifically designed for professional use. Researching and contacting these suppliers can be a great way to find top-notch applicators.

Remember to consider factors such as the type of applicator (brush, roller, or pad) and the specific requirements of your project before making a purchase. Reading product descriptions and customer reviews can help you make an informed decision.