I Tested And Reviewed 7 Best Glue For Plastic To Wood (2023)

Choosing the best glue for plastic to wood can be a tricky task. With so many options on the market, it's important to consider the job at hand and select the right adhesive for your project. When searching for the perfect plastic-to-wood glue, here are some key factors to keep in mind.

First, examine the materials you're bonding. Is the plastic ABS, PVC, acrylic, or something else? Understanding the type of plastic will help narrow your adhesive search. Additionally, look at the wood surface. Is it finished or unfinished? Smooth or porous? The wood texture impacts glue effectiveness.

Next, think about required bond strength. For load-bearing joints, a robust epoxy or polyurethane-based glue is best. For lighter tasks, cyanoacrylate "super glues" quickly form rigid bonds. There are also multifunction adhesives that work on both plastics and wood while providing flexibility.

Also, consider drying time. Do you need a fast-setting glue for time-sensitive projects? Or is an extended working time preferable to adjust pieces and achieve precision? These factors all play a role in selecting the ideal plastic-to-wood adhesive.

Doing your homework before gluing plastic to wood is the key to success. With the right adhesive choice, you can create durable, long-lasting bonds tailored to your specific application. Test options to determine what works best, and your materials will come together seamlessly. The perfect glue is out there – finding it just takes research.

7 Best Glue For Plastic To Wood

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for bonding various materials like wood, fabric, glass, metal, stone, and more.

|

|

||

|

2

|

The product is ideal for Instant bonding of wood, plastic, metal, leather, ceramic, and craft materials, making it ideal for woodworking and crafts.

|

|

||

|

3

|

The product is ideal for repairing and bonding plastic, wood, metal, crafts, and various other materials.

|

|

||

|

4

|

The product is ideal for bonding plastic, wood, metal, crafts, and repair projects.

|

|

||

|

5

|

The product is ideal for various applications requiring a strong and clear adhesive bond.

|

|

||

|

6

|

The product is ideal for bonding plastic, wood, metal, crafts, and repairs quickly and securely.

|

|

||

|

7

|

The product is ideal for projects that require a strong and transparent bond.

|

|

1. Weldbond Multi-Surface Adhesive Glue: Versatile, Non-Toxic Bonding

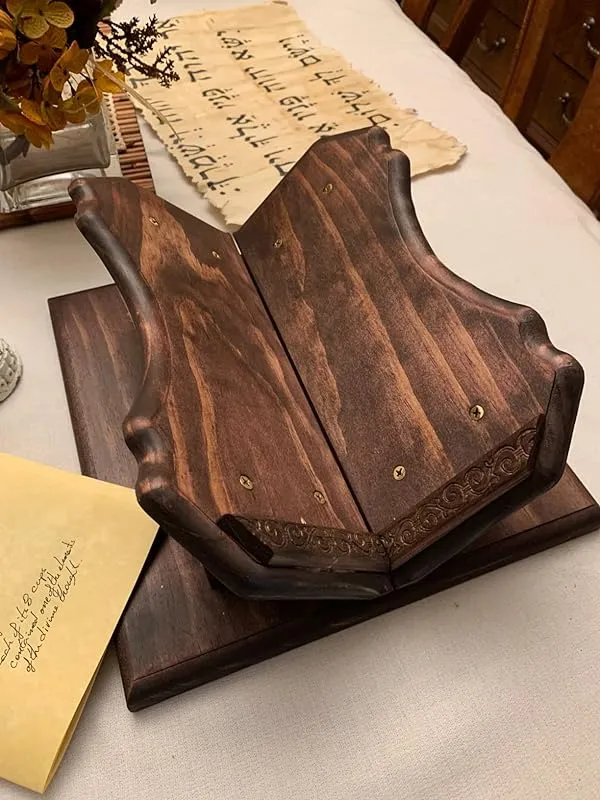

The metal hooks I purchased were perfect for attaching metal to my wooden fence. I used them to train climbing roses and they have held up well. The glue claims to dry in an hour, but due to the cold weather, I left it for 24 hours just to be sure. The drying process was efficient, and the hooks have remained securely attached.

I also used this glue to refoam my 1985 Sony APM speakers, and I am amazed at the results. Even after 4 months, the speakers still sound like new. The glue dries crystal clear, leaving no visible marks around the foam. It has truly restored the speakers to their original quality.

In addition, I have found this product to be the only one suitable for adhering glass to glass in a mosaic glass project. It leaves no residue or marks on the glass, providing a clean and seamless finish. It is a reliable option for any mosaic enthusiast.

I must say that this glue is by far the best I have ever used. It offers the strength of super glue while also allowing for some flexibility in positioning the glued pieces. Despite some negative reviews I have come across, I completely disagree with their views. This glue is in no way comparable to Elmer's glue, except for its appearance when wet. It outperforms Elmer's in every aspect.

Regarding the claim that it does not dry clear, I have found that those who made such statements simply did not wait for it to dry completely. With a couple of hours of drying time, this glue does dry clear, as advertised. I used it for a mosaic project and instantly fell in love with its performance.

Lastly, I had no prior experience in laying a mosaic backsplash in my bathroom, but with the help of this glue, I completed the job like a professional in just 10 minutes. Well Bond is an awesome product that I highly recommend to anyone seeking reliable and efficient adhesive. Don't hesitate to buy it if you want outstanding results.

2. Mitreapel Instant Bond Woodworking Glue – 2 Pack

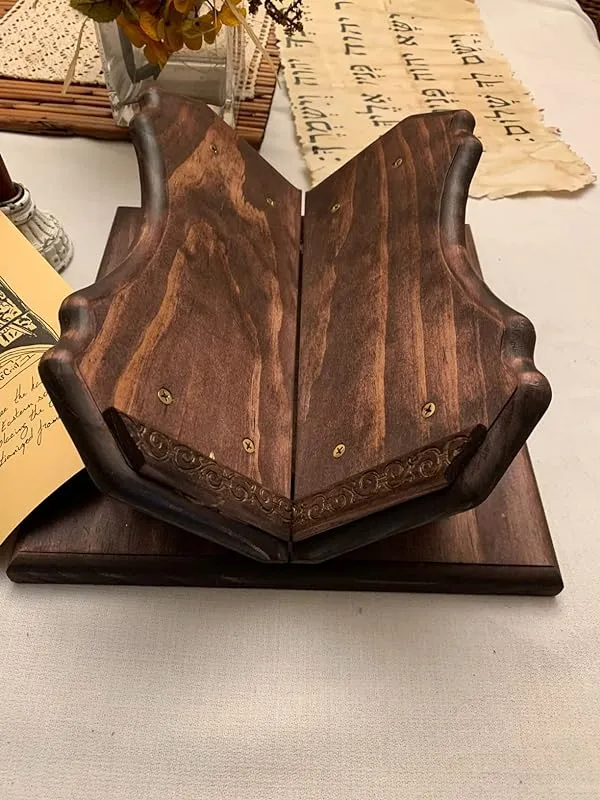

The MITREAPEL CA Glue with Activator is a top-notch adhesive set that is perfect for a variety of applications. The quality and performance of the adhesive are truly impressive. MITREAPEL is a trusted brand known for its exceptional adhesives, and this product lives up to that reputation. The CA glue provides a strong and durable bond, making it ideal for woodworking, plastics, metals, leather, and more.

One of the standout features of this product is the inclusion of two sizes of CA glue and activator. The 1.7 oz (50 ml) bottles of glue are great for smaller projects or precision applications, while the 6.7 fl oz (200 ml) bottles are perfect for larger-scale projects or frequent use. This versatility allows you to choose the appropriate amount of adhesive based on your specific needs.

The fast-curing properties of this CA glue are also worth mentioning. When used in conjunction with the activator, the glue sets quickly, reducing the wait time for the bond to form. This is especially useful for woodworking projects that require immediate or time-sensitive assembly. The fast cure time ensures efficient workflow and minimizes downtime.

Another impressive aspect of this product is its compatibility with various materials. It adheres well to wood, plastic, metal, leather, and other common materials used in woodworking and crafting. Whether you're joining wooden pieces, repairing broken plastic items, or bonding metal components, this adhesive provides a reliable and durable connection.

The activator included in the set enhances the performance of the CA glue. It accelerates the curing process and ensures a strong bond in a shorter amount of time. The activator is easy to use and consistently delivers reliable results, making application hassle-free and ensuring reliable adhesion.

The precision applicator tips on the CA glue bottles offer controlled and targeted dispensing of the adhesive. This helps prevent wastage and ensures clean application, especially in small or delicate areas. The bottles are designed to minimize clogging and maintain the freshness of the glue for extended periods.

3. Quick-Dry Glass And Super Glue Combo Pack

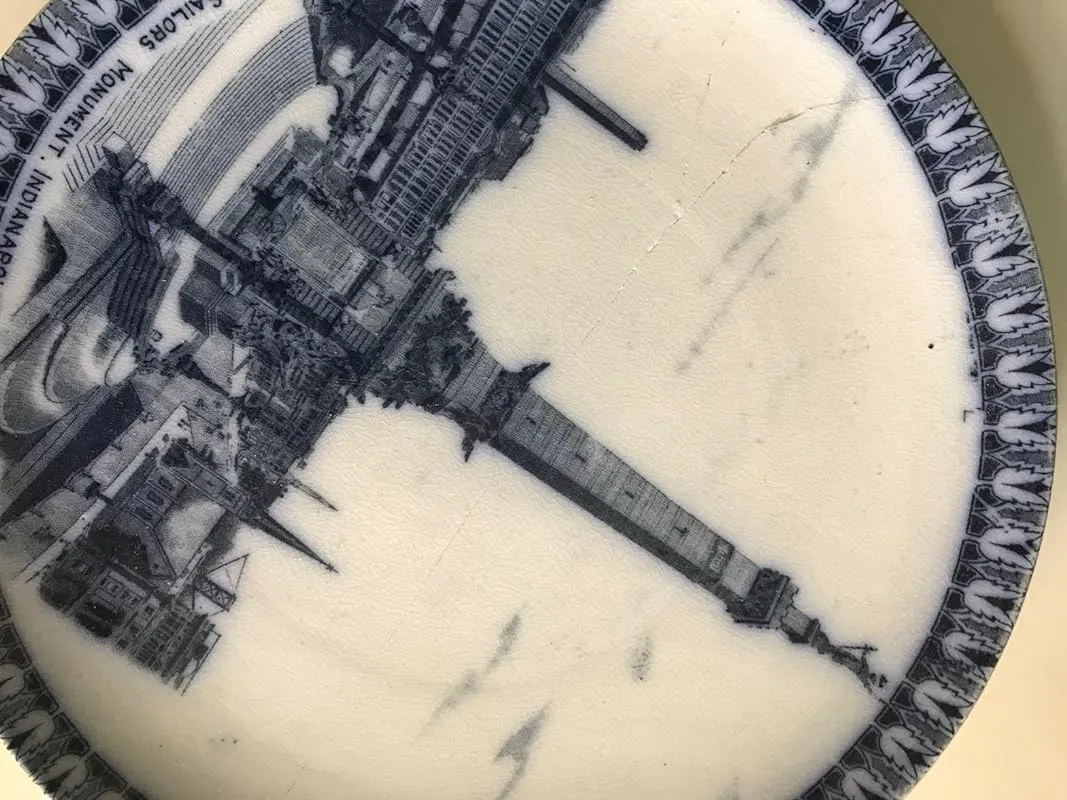

Loctite Glass Glue: The Ultimate Solution for Repairing Broken Ornaments

When it comes to repairing delicate items like ornaments and glassware, finding the right adhesive can be a challenge. That's why I was thrilled to discover Loctite Glass Glue. After breaking a Swarovski star ornament, I was devastated, but this glue came to the rescue.

One of the standout features of Loctite Glass Glue is its ease of use. Unlike other adhesives that require clamping, this glue eliminates the need for any extra tools or equipment. Simply apply a thin line of glue along the broken edges, hold it together for one minute, and voila – the bond is strong and secure.

What impressed me the most about this glue was its transparency. Once dried, it becomes virtually invisible, making it impossible to detect any repairs. Whether it's a ceramic ornament or a cherished keepsake, Loctite Glass Glue seamlessly blends in, leaving no trace of its presence.

Durability is another key factor to consider, especially when it comes to fragile items. Loctite Glass Glue exceeded my expectations in this regard. It creates a strong bond that can withstand accidental bumps and falls, ensuring that your repaired item stays intact for years to come.

One of the standout uses of this glue was repairing a broken plate with sentimental value. The break was clean, and Loctite Glass Glue managed to restore it to its former glory. Now, the plate hangs proudly on my wall instead of being tucked away on a bookshelf, safe from potential accidents.

Moreover, this glue demonstrates its versatility by working not only on glass but also on ceramic surfaces. It outperforms traditional superglue options by providing a fully transparent bond that remains strong even when subjected to the dishwasher.

In terms of application, Loctite Glass Glue offers a forgiving nature. It allows you a few seconds to correct any misalignments before fully bonding the pieces together. This feature ensures that even if you make a mistake, you can still achieve a seamless repair.

Having experienced the effectiveness of Loctite Glass Glue firsthand, I couldn't resist recommending it to my friends who often find themselves in need of a reliable adhesive for their glass repairs. Its easy application, transparent finish, and exceptional durability make it a must-have for anyone dealing with broken glassware or ornaments.

4. Loctite Super Glue: Quick-Dry, Longneck Bottle For All Repairs

I am impressed with the design of this glue, particularly the long stem and tight cover with a slim needle. This design ensures that the glue remains fresh and prevents the opening from gluing shut. I have had several instances where I reached for a tube of glue only to find it dried out, so I appreciate the effort put into keeping this glue fresh.

In terms of performance, this glue works just like any other instant glue. I have used it for attaching nail charms and rhinestones, and it has provided a strong and secure hold. The guarantee stick ensures that the charms and rhinestones won't fall off easily. Only a small drop of this glue is needed, which is convenient.

One of the standout features of this glue is its longevity. Unlike other brands I have used, this glue lasts a long time without drying up. I do find that it takes a bit longer to set and dry compared to other brands, but for me, the extra time is worth it considering the container's longevity. To further preserve its shelf life, I store the container in a plastic zip lock sandwich bag inside a cabinet.

The adhesion strength of this brand is very good, which is why it remains my first choice for super glues. Although I may still try other brands in the future, I am satisfied with the performance of this glue.

I must mention that this glue has exceeded my expectations in terms of durability. The last bottle I purchased lasted over five years without clogging the tip, which is remarkable. It is far superior to the small tubes that tend to dry out quickly after opening.

Lastly, I used this glue to fix my plastic display bolt on my wheel cover. With just a small drop of this fast-drying glue and holding it in place for 15 seconds, the bolt is now securely back on.

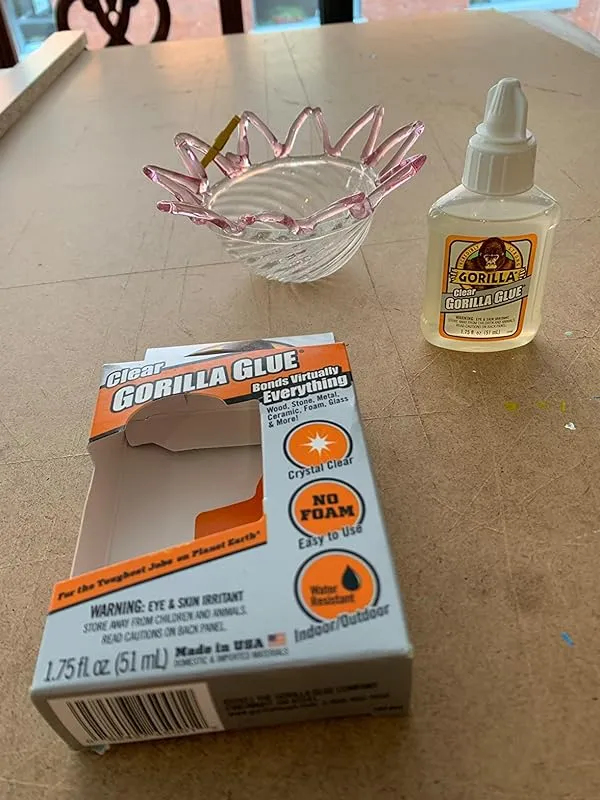

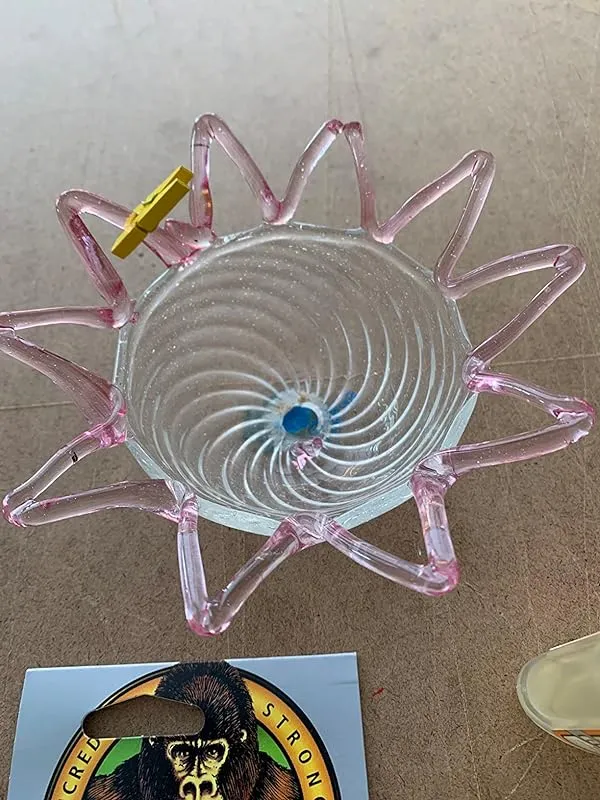

5. Gorilla Clear Glue, 1.75 Ounce Bottle, Clear (Pack Of 1)

I recently had the opportunity to try out Gorilla Clear Glue, and I must say, it exceeded my expectations. This adhesive is a game-changer when it comes to household projects and DIY tasks.

One of the standout features of Gorilla Clear Glue is its crystal-clear finish. Unlike other adhesives that leave behind a visible residue, this glue blends seamlessly with the materials being bonded. This makes it perfect for projects where appearance is crucial.

Not only does Gorilla Clear Glue deliver on aesthetics, but it also provides a strong and durable bond. I was pleasantly surprised to find that the bond created by this glue is long-lasting and reliable. I used it on various materials such as wood, plastic, glass, ceramic, and metal, and it worked effectively on all of them.

The nozzle design of this glue allows for precision application, ensuring that you can apply it exactly where you need it. This feature is especially useful when working with delicate or intricate pieces. I found that I could easily control the amount of glue dispensed, resulting in a clean and professional-looking finish.

Furthermore, Gorilla Clear Glue is non-foaming, which means it doesn't expand during the drying process. This eliminates the risk of messy overflow and ensures a clean and precise bond. The glue dries quickly, saving you time and allowing you to move on with your project.

The compact size of the 1.75-ounce bottle is another advantage of this glue. It is easy to store and doesn't take up much space in your toolbox. This makes it convenient to have on hand for any future projects that may arise.

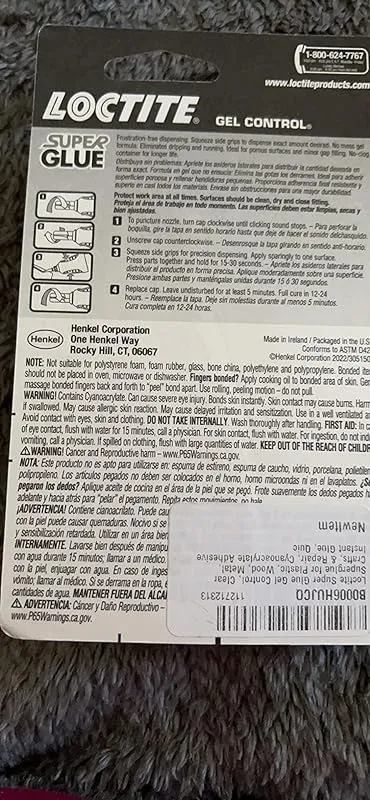

6. Loctite Gel Control Clear Super Glue Kit

Loctite Gel Superglue has truly revolutionized my bonding projects with its exceptional performance. This adhesive has exceeded my expectations and has become my go-to choice for all my DIY projects and repairs.

One of the standout features of Loctite Gel Superglue is its convenient gel formula. Unlike runny liquid glues, the gel consistency stays in place, allowing for precise application without any mess or drips. This gives me complete control over the amount of glue I need, ensuring a clean and accurate bond every time.

The strength and durability of this superglue are simply outstanding. It forms a powerful bond that can withstand the test of time and extreme conditions. Whether I'm fixing broken items or securing materials together, Loctite Gel Superglue provides a strong and long-lasting bond that I can rely on.

What sets this product apart is its remarkable versatility. It works seamlessly on various surfaces, including metal, plastic, wood, ceramics, and more. Regardless of the material, Loctite Gel Superglue delivers reliable adhesion, making it suitable for a wide range of projects.

I also appreciate the precision applicator that comes with the product. It allows me to apply the glue exactly where I need it, even in tight or hard-to-reach spaces. This level of precision ensures that the adhesive goes exactly where it's supposed to, eliminating any guesswork or potential mess.

Another valuable feature of Loctite Gel Superglue is its quick drying time. It sets within seconds, saving me precious time during my projects. This fast-drying property is particularly useful when I'm working on multiple tasks or time-sensitive repairs.

7. Gorilla Clear Glue, 5.75 Ounce Bottle, Clear

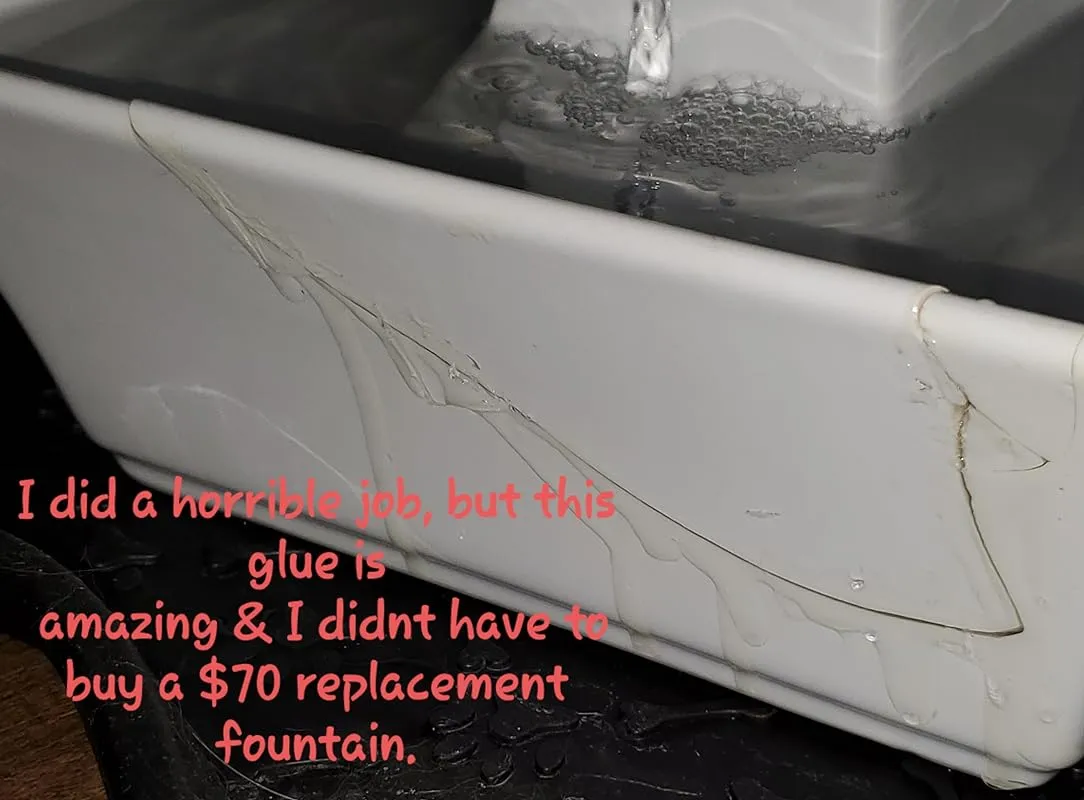

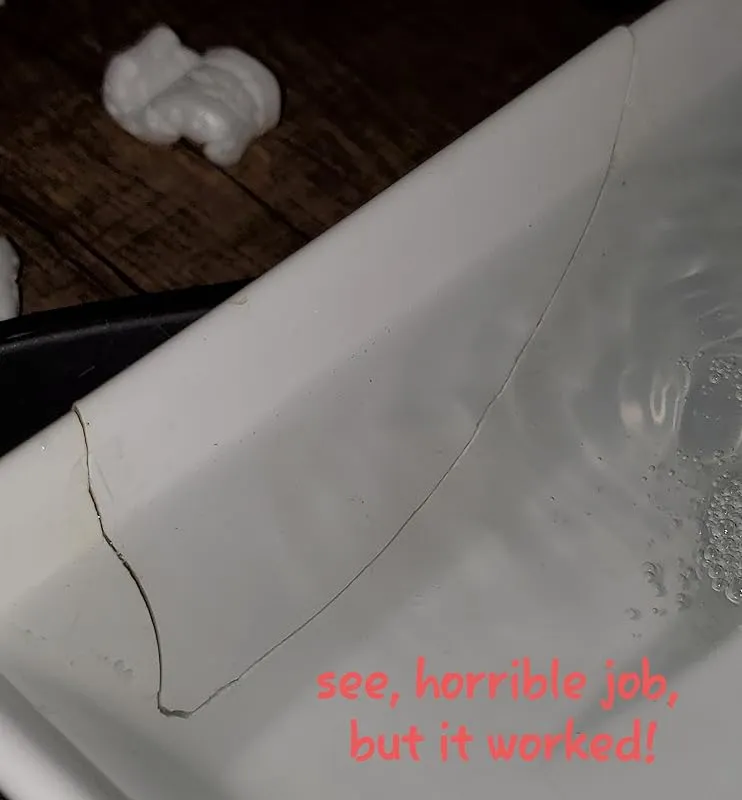

The Gorilla Glue is an exceptional product that provides impressive results. With proper ventilation, it fully cures within 15 to 20 hours. It is important to note that a thick coat is not recommended, as the glue settles naturally to the desired thickness. For clean up, it is best to wipe off any excess glue with a dry tissue or cloth before rinsing off with running water.

One of the standout features of this glue is its ability to be layered without obvious signs of layering, except for a slightly increased thickness. This makes it ideal for glazing projects. When used for adhesion, a wet surface and a strong press will result in a permanent bond.

In terms of sealing, the Gorilla Glue dries to a crystal clear and shiny finish. It is important to avoid touching it before it is fully cured, as this can affect the final shine. It should be noted that this product is not suitable for careless or grade school projects, as it requires precision and careful handling.

The Gorilla Glue is also available in a larger size, which is great for those who require more of the product. However, it may be difficult to find the larger size in local stores. Despite this, the price of the glue is reasonable.

One user mentioned that they would normally use E6000 for their project, but decided to try the Gorilla Glue instead. They followed the instructions meticulously and were impressed with the results. The glue successfully attached a Hurricane vase and candle sticks together, as shown in the accompanying picture.

The only slight downside mentioned by a user is the absence of a cover for the tube. While the user expected to receive one, none was provided. However, this does not significantly impact the overall experience with the glue.

FAQs

Are there any alternative methods or materials that can be used instead of glue to bond plastic to wood?

Yes, there are alternative methods and materials that can be used to bond plastic to wood. One option is using screws or nails to mechanically fasten the two materials together. This method provides a strong and durable bond, especially when combined with the use of adhesive materials.

Another alternative is using epoxy resin or polyurethane adhesive. These adhesives have excellent bonding properties and can create a strong bond between plastic and wood. It is important to ensure that the adhesive is suitable for both plastic and wood surfaces and follow the manufacturer's instructions for proper application and curing.

Additionally, some specialty tapes, such as double-sided adhesive tapes or acrylic foam tapes, can also be used to bond plastic to wood. These tapes provide a quick and easy bonding solution, especially for lightweight applications.

It is recommended to test the chosen alternative method or material on a small, inconspicuous area before applying it to the entire surface to ensure compatibility and desired bonding strength.

Are there any specific brands or products that have been recommended for bonding plastic to wood?

When it comes to bonding plastic to wood, there are a few specific brands and products that have been recommended by professionals and users alike. One popular option is the 3M Super 77 Multipurpose Adhesive.

This adhesive is known for its strong bonding power and versatility, as it can bond a variety of materials including plastic and wood. Another commonly recommended brand is Loctite, which offers various adhesives suitable for bonding plastic and wood surfaces together.

Their Plastic Bonding System and Epoxy Plastic Bonder are often praised for their reliability and durability. Additionally, Gorilla Glue is another esteemed brand that offers adhesives specifically designed for bonding plastic to wood.

It is important to carefully follow the instructions provided by the manufacturer when using any adhesive to ensure proper application and the best possible bond.

Are there any specific factors to consider when choosing a glue for plastic to wood bonding, such as temperature resistance or water resistance?

When choosing a glue for plastic to wood bonding, there are several factors to consider to ensure a strong and durable bond. One important factor is temperature resistance. If the bonded materials will be exposed to high temperatures, it is crucial to select a glue that can withstand those conditions without weakening or melting.

Look for glues that are labeled as heat-resistant or have a high temperature tolerance.

Another factor to consider is water resistance. If the bonded materials will be exposed to moisture or water, it is essential to choose a glue that is waterproof or water-resistant. This will prevent the bond from deteriorating over time due to moisture absorption or water damage.

Additionally, it is important to consider the type of plastic and wood involved. Different glues work better with certain types of materials, so be sure to check the compatibility of the glue with the specific plastics and wood you are bonding.

In summary, when selecting a glue for plastic to wood bonding, consider factors such as temperature resistance, water resistance, and compatibility with the materials involved to ensure a successful and long-lasting bond.

Are there any specific precautions or preparation steps necessary before using glue to bond plastic to wood?

Yes, there are some specific precautions and preparation steps that are necessary before using glue to bond plastic to wood. Here are a few recommendations:

1. Clean the surfaces: Ensure that both the plastic and wood surfaces are clean and free from dust, dirt, grease, or any other contaminants. This can be done by wiping the surfaces with a clean cloth or using a mild detergent solution, followed by thorough drying.

2. Sand the surfaces: It is advisable to lightly sand both the plastic and wood surfaces to create a rough texture. This will help the glue adhere better and increase the bond strength.

3. Choose the right adhesive: Select a glue that is suitable for bonding plastic to wood. Some popular options include epoxy, cyanoacrylate (super glue), or polyurethane adhesive. Read the manufacturer's instructions to ensure compatibility with both materials.

4. Apply the glue properly: Follow the instructions provided by the glue manufacturer, including the recommended application method and amount. Use a brush or applicator to evenly distribute the adhesive on both surfaces.

5. Clamp or hold the pieces together: After applying the glue, firmly press the plastic and wood surfaces together. Use clamps or hold the pieces in place for the recommended drying time specified by the adhesive manufacturer.

Remember to always refer to the specific instructions provided by the glue manufacturer for the best results.

Are there any specific techniques or application methods for using glue to bond plastic to wood?

Yes, there are specific techniques and application methods for bonding plastic to wood using glue. Here are a few options:

1. Choose the right adhesive: Select a glue that is specifically formulated for bonding plastic and wood. Epoxy, polyurethane, or cyanoacrylate (super glue) are commonly used for this purpose.

2. Prepare the surfaces: Ensure that both the plastic and wood surfaces are clean, dry, and free from any dust, grease, or debris. Sanding the wood surface lightly can improve adhesion.

3. Apply the glue: Depending on the type of adhesive chosen, follow the manufacturer's instructions for application. Generally, apply a thin, even layer of glue to one of the surfaces.

4. Join the surfaces: Press the plastic and wood together firmly, aligning them properly. Apply clamping or holding pressure as recommended by the adhesive manufacturer.

5. Allow curing time: Let the glued surfaces dry and cure according to the adhesive instructions. This can range from a few minutes to several hours, depending on the adhesive used.

It's worth noting that the success of the bond may also depend on the specific type of plastic and wood being used. If you're unsure about which adhesive to choose or require more specific guidance, consulting with a professional or the adhesive manufacturer directly would be advisable.

Are there any specific types of plastic or wood that are more challenging to bond together using glue?

Yes, there are certain types of plastic and wood that can be more challenging to bond together using glue. When it comes to plastics, some types have low surface energy and are inherently difficult to bond, such as polyethylene and polypropylene.

These plastics have non-polar surfaces, which makes it hard for traditional adhesives to form strong bonds. However, there are specialized adhesives available, such as cyanoacrylates or epoxies, which can bond these challenging plastics effectively.

As for wood, certain types can be more difficult to bond due to their natural characteristics. For example, woods with high oil or resin content, like teak or rosewood, may pose challenges in achieving a strong bond with traditional wood glues.

In such cases, using specialized wood adhesives that are specifically designed for oily or resinous woods can help overcome the bonding difficulties.

If bonding difficult-to-glue plastics or woods, it is advisable to consult with adhesive manufacturers or experts who can recommend the most suitable adhesive for the specific materials being used.

Can glue be used to bond plastic to different types of wood, such as hardwood or plywood?

Yes, glue can be used to bond plastic to different types of wood, including hardwood and plywood. However, it is important to choose the right type of glue for the job.

For bonding plastic to wood, one commonly used adhesive is epoxy glue. Epoxy glue is known for its strong bonding properties and can create a durable and long-lasting bond between plastic and wood surfaces.

It is important to follow the manufacturer's instructions for proper application and curing time when using epoxy glue.

Another option is using a polyurethane-based adhesive, which is suitable for bonding plastic to wood. Polyurethane adhesives are known for their flexibility and ability to bond different materials together.

They provide a strong bond and are resistant to moisture, making them suitable for outdoor applications as well.

Before applying any glue, it is essential to properly clean and prepare the surfaces to be bonded. This involves removing any dirt, grease, or old adhesive residues to ensure a strong bond. Additionally, it is advisable to test the adhesive on a small, inconspicuous area before applying it to the entire project to ensure compatibility and desired results.

Overall, with the right adhesive and proper surface preparation, you can successfully bond plastic to different types of wood.

Can regular wood glue be used to bond plastic to wood?

Regular wood glue is not typically recommended for bonding plastic to wood. Wood glue is specifically designed to bond porous surfaces, such as wood, by penetrating the fibers and creating a strong bond.

Plastic, on the other hand, is non-porous and does not provide the necessary surface for wood glue to adhere to effectively.

To bond plastic to wood, it is recommended to use a specialized adhesive that is designed to work with both materials. Epoxy adhesives or cyanoacrylate (super glue) can be effective options for bonding plastic to wood.

These adhesives have properties that allow them to bond to non-porous surfaces like plastic, while still providing a strong bond with the wood.

Before applying any adhesive, it is important to clean and prepare both the plastic and wood surfaces to ensure proper adhesion. This can be done by lightly sanding the wood and cleaning the plastic with a suitable cleaner.

Following the instructions provided by the adhesive manufacturer is also crucial for achieving the best results.

How long does it typically take for glue to fully bond plastic to wood?

The time it takes for glue to fully bond plastic to wood can vary depending on several factors. The type of glue used, the materials being bonded, and the environmental conditions can all affect the bonding time.

Generally, most types of glue require some drying or curing time to achieve maximum bond strength. Some fast-drying glues may bond within a few minutes, while others may take several hours or even a day to fully cure.

It is important to follow the manufacturer's instructions on the glue packaging to determine the recommended curing time.

Additionally, the surface preparation of both the plastic and wood can impact the bonding time. It is essential to clean and dry the surfaces thoroughly before applying the glue to ensure optimal adhesion.

If you are looking for a faster bonding option, you may consider using a specialized adhesive designed for plastic-to-wood bonding, such as epoxy or cyanoacrylate (super glue). These adhesives often have shorter curing times and provide strong bonds.

Ultimately, it is best to consult the specific product instructions or the manufacturer for accurate information on the bonding time for a particular glue.

What is the best type of glue to use when bonding plastic to wood?

When bonding plastic to wood, it is important to choose a glue that is specifically designed for this purpose. One of the best types of glue to use in this scenario is epoxy adhesive. Epoxy adhesive is known for its strong bonding capabilities and ability to adhere to a wide range of materials, including plastic and wood.

It provides excellent adhesion and durability, ensuring a long-lasting bond between the two surfaces.

Another option to consider is polyurethane adhesive. This type of glue also has strong bonding properties and is suitable for bonding plastic to wood. It forms a flexible and durable bond, which is particularly beneficial when joining materials that may experience movement or stress.

It is advisable to read and follow the manufacturer's instructions carefully when using any glue. Additionally, it is recommended to conduct a small test on a hidden area of the surfaces to ensure compatibility and adhesion before applying the glue to the entire area.