I Tested And Reviewed 8 Best Moisture Barrier For Concrete Floor (2023)

Installing a moisture barrier is one of the most important steps when finishing a concrete floor. A proper moisture barrier creates a permanent separation between the slab and your finished flooring, preventing moisture from seeping through and damaging floor coverings or creating an unhealthy indoor environment. When researching the best moisture barrier for concrete floors, there are a few key factors to consider.

First, examine the concrete floor itself and understand any existing moisture issues. New concrete slabs especially may have very high moisture vapor emission rates that require a more robust moisture barrier. Testing the concrete moisture levels first will determine what kind of barrier is needed. Additionally, consider the type of flooring that will be installed. More porous coverings like wood or vinyl plank require more moisture protection underneath than an epoxy coating or tile.

What questions should you be asking when choosing a moisture barrier? How thick should the barrier be to adequately protect against moisture? Does it create a complete seal across the entire slab or are there potential gaps? Is the material both a vapor barrier and moisture barrier? Does the barrier need any kind of special preparation on the concrete before installation? Paying attention to these aspects will ensure you select the optimal moisture barrier for your project.

A properly installed moisture barrier is invaluable for long-lasting, high-performance flooring. Taking the time to test concrete slab moisture, understand flooring needs, and evaluate barrier characteristics will lead to making the best choice. With the right moisture barrier in place, you can install beautiful, durable finished floors with confidence.

8 Best Moisture Barrier For Concrete Floor

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for providing moisture protection and sound reduction under solid & engineered wood floors and LVP.

|

|

||

|

2

|

The product is ideal for providing sound reduction, moisture protection, and compression resistance for laminate and wood flooring installations.

|

|

||

|

3

|

The product is ideal for providing insulation, soundproofing, and moisture protection under various types of flooring.

|

|

||

|

4

|

The product is ideal for insulating and waterproofing crawlspaces, providing weatherization and meeting fire codes requirements.

|

|

||

|

5

|

The product is ideal for providing a self-adhesive, waterproof barrier for weatherization and protection against moisture intrusion.

|

|

||

|

6

|

The product is ideal for providing a stable and moisture-resistant base for flooring installations.

|

|

||

|

7

|

The product is ideal for providing moisture barrier protection under flooring installations.

|

|

||

|

8

|

The product is ideal for providing sound reduction, compression resistance, and moisture protection for laminate and floating wood flooring installations.

|

|

1. Roberts Wood Floor Silicone Underlayment: Moisture Barrier & Protection

I recently purchased a roll of this product to use as a protective layer on my workshop glue table, and I must say, it exceeded my expectations. I primarily use Gorilla Glue and TiteBond, and neither of them stick to this paper. Once the glue dries, it simply falls off, and the TiteBond peels off easily without any issues. The paper itself is quite durable, and with a little caution, the clamps do not tear it up. I have already used it for multiple projects and have not needed to change the paper yet. While I cannot say if one roll will last a lifetime, it certainly seems like it will last a good long time, saving me countless hours of cleaning up dried glue.

Installation was a breeze. I was initially worried after reading reviews about tearing and rippling causing uneven heights for flooring installation. However, I was pleasantly surprised. My subfloor is an old 55-year-old 2×6 T&G with slight cupping. After sanding down the high spots, I had no major issues with the vapor seal. There were some minor ripples, as expected with my old subfloor, but they did not impact the installation of my 3-1/4" wide white oak flooring. I found that rolling out one row at a time minimized rippling and tearing. In fact, I did not experience any tearing of the product, contrary to what other reviews had stated.

I am thoroughly impressed with this product. It is inexpensive, easy to work with, and should be vapor permeable. Moreover, it is much sturdier than rosin paper and does not have any unpleasant odor or staining like tar paper. I highly recommend this product to anyone in need of a reliable and efficient damp blocker.

However, it is important to note that this paper should not be mistaken for a suitable underlayment on its own. It works great for blocking out dampness, but you will still need to use proper underlay for your flooring if it is above ground and not above a basement.

I used this paper under my 3/4" unfinished hickory flooring, and it proved to be a fantastic choice. It lays out flat without much curl and provides a great surface for racking. The white color serves as a nice backdrop for setting up and ensures that the flooring slides easily without tearing. The low friction of the paper makes it effortless to fit the end joints tightly. Additionally, it is lightweight, easy to use, clean to work on top of, and reasonably priced. I am extremely satisfied with this product and would definitely use it again in the future.

2. Silentguard: Superior Laminate Flooring Underlayment With Moisture Protection

This underlayment is definitely worth the investment. It is easy to install and can be cut with a blade, making the process quick and hassle-free. In just a few minutes, you can lay it down in a guest bathroom or any other room. One of the standout features of this underlayment is its ability to reduce noise, making it a major upgrade from similar products found in big box stores. Plus, it comes at a great price, making it a cost-effective choice.

Contrary to some reviews, I found the installation of this underlayment to be quite simple. The adhesive strips worked well, and all I needed to do to cut it was score the plastic side and rip the backing with my fingers. No need for scissors! The underlayment lays down smoothly and flat, providing a solid foundation for your flooring.

I highly recommend opting for the "plus" version of this underlayment, as it includes parts for attaching it to the next row when covering a floor. This feature greatly enhances the overall installation process. Additionally, the underlayment effectively reduces footfall noises, making it perfect for rooms above garages or in duplexes where noise transfer is a concern.

Having previously used Quiet Walk products for our home remodeling, we were confident in choosing them again for our flooring needs. They have proven to be durable and reliable, delivering on their promises. However, the adhesive provided to connect the layers was not as user-friendly as expected. It resulted in a wrinkly mess, causing frustration during installation. We ended up using duct tape to secure the layers, which worked well. It would be great if the adhesive system could be improved to eliminate the need for additional purchases.

On a positive note, the shipping service for this product was exceptional. Despite the projected arrival time of 10-14 days, the underlayment arrived within just 3 days on both occasions we ordered. This prompt delivery was greatly appreciated and made our experience even more satisfactory.

3. Amerique Premium 3mm Thick Flooring Underlayment – Royal Blue (Pack Of 3)

The insulation provided with this product is 3mm thick, which is a decent thickness for insulation purposes. One of the standout features of this product is its affordability. In comparison to similar products available at popular home improvement stores like Home Depot or Lowe's, this product is significantly cheaper. This cost-effectiveness makes it a great choice for those looking for insulation solutions on a budget.

While it may not be as user-friendly as some other brands available in big box stores, the quality of this product is still commendable. It may require a bit of practice to get the hang of using it, but once you become familiar with the installation process, it becomes much easier. Additionally, the attached tape strip makes it convenient to lay out and attach to the next piece, eliminating the need for additional tape.

The reviewer mentions that they would buy this product again, which indicates their satisfaction with its performance. Another reviewer mentions that although it may not be as easy to use as other brands, it is still of good quality. This highlights the value for money aspect of this product, as it offers a comparable quality at a fraction of the price.

Lastly, one reviewer mentions that they were unable to test the product due to excessive rainfall in their area. While this doesn't provide much information about the product itself, it does show that they have faith in its ability to perform the intended job.

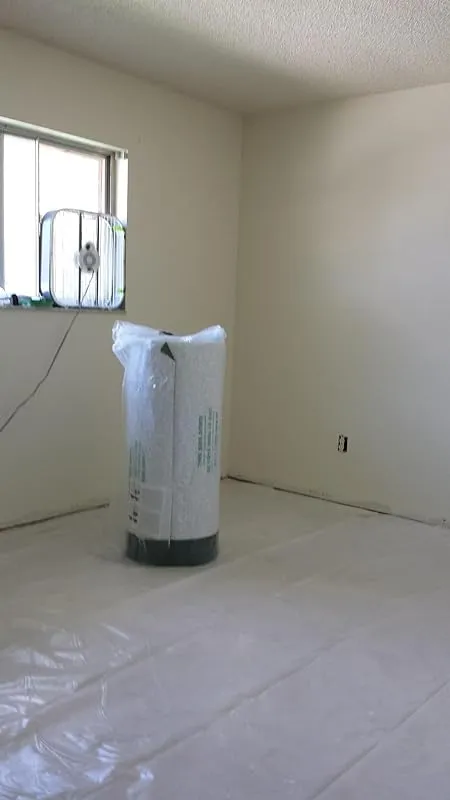

4. Solid White Crawlspace Flooring Underlayment: Us Energy Pro+

The 2 roles of this vapor barrier were more than sufficient to cover my entire crawlspace, which is approximately 1400 square feet. With the proper vapor barrier tape and spikes, the installation process took me about 10 hours to complete on my own. I was pleasantly surprised by the durability of this product, as it is extremely difficult to tear. The quality and value of this vapor barrier exceeded my expectations.

I highly recommend this fantastic barrier product. However, it is important to purchase the tie downs and tape specifically designed for this product in order to ensure proper installation. With the necessary accessories, this vapor barrier worked perfectly for my crawl space.

The product consists of two layers, with one side being foil and the other side being white. The instructions state to place the foil side down, but due to the way the product is rolled up, it can be challenging to achieve this. This aspect was slightly frustrating during the installation process. Nonetheless, the vapor barrier has performed well so far.

It is worth noting that the description of the product is slightly incorrect, as it claims that both sides are white. In reality, one side is white while the other side is reflective like foil. Regardless of this discrepancy, the vapor barrier is rip-resistant and not flimsy at all. It can be easily cut with sharp scissors as needed. Overall, it does an excellent job in providing effective insulation.

I also used this product to cover the insulation in the ceiling of my unfinished basement. Previously, an insulation installation company had installed a subpar vapor barrier that was difficult to cut straight. In contrast, this vapor barrier was tough but easy to cut, making the installation process much smoother. I am highly satisfied with the results and will definitely purchase more in the future. I highly recommend this product to anyone in need of a reliable and easy-to-install vapor barrier.

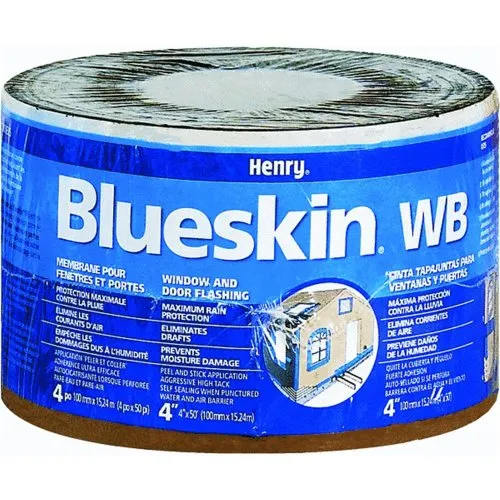

5. Blueskin Weather Barrier – Waterproof Membrane, 50 Ft – Henry

The Blueskin WB sealing tape is an excellent product with a strong adhesive that sticks to almost anything. It is particularly useful in cold weather due to its low application temperature. The tape comes in a variety of widths, making it versatile for different applications, such as flashing around windows and doors. One side of the tape is bright blue plastic, while the sticky side is black.

To ensure precise application, some users recommend drawing guide lines with a level and a Sharpie marker before applying the tape. The seal created by Blueskin WB is watertight, as confirmed by a user who experienced heavy rainstorms without any leakage between the wall and concrete slab.

Many customers have found this product to be an excellent purchase. It can be used not only for sealing joints on plywood, but also for emergency patch repairs on leaking gutters. It has even been used to hold down carpeting. Although more expensive than duct tape, Blueskin WB offers superior performance.

The price of the product is reasonable, and it arrives promptly. However, some users have mentioned that the shipping costs from the current Amazon supplier are quite high, which has led them to switch to other products.

6. Roberts First Step Premium Underlayment – 630 Sq. Ft. Roll – 40" X 189' X 2 Mm

I recently purchased the First Step underlayment for my laminate flooring installation and I must say, I am extremely pleased with the results. This product exceeded my expectations in terms of quality and performance.

The underlayment is made of a durable material, which eliminates the need for an additional moisture barrier. It is evident that the sides of the underlayment are made of sturdy 1-2 mil material. This ensures that the underlayment provides excellent protection and support for the flooring.

One of the standout features of this underlayment is its soundproofing capabilities. It effectively muffles the sound of footsteps and other noises, making my home much quieter and more peaceful. Additionally, it also acts as an insulator, keeping my floors warm and comfortable.

The ease of installation was another highlight of this product. It was incredibly easy to lay down and cut, and I was able to achieve a seamless installation without any hassle. I simply used scissors to cut the underlayment to the desired size, and it fit perfectly.

In terms of price, the First Step underlayment offers exceptional value for money. It is significantly more affordable than similar products available at big box stores. In fact, I compared it to the popular red-colored Air Guard underlayment and found that the First Step not only had more filling but also cost half as much. It truly is a cost-effective option without compromising on quality.

I also appreciate the fact that this underlayment can be easily stored. It rolls tightly and can be stored flat, making it convenient for future use or for any leftover pieces.

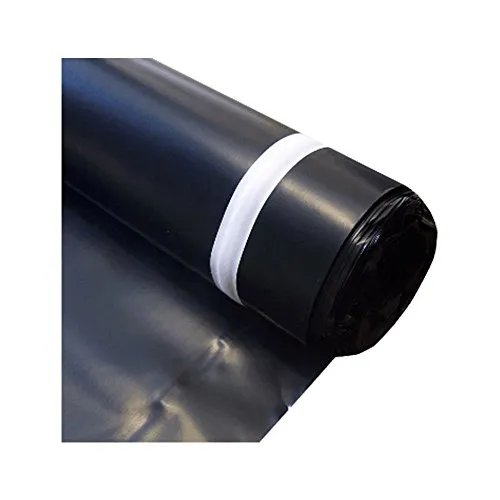

7. Mp Global 6 Mil Moisture Barrier Film – Black

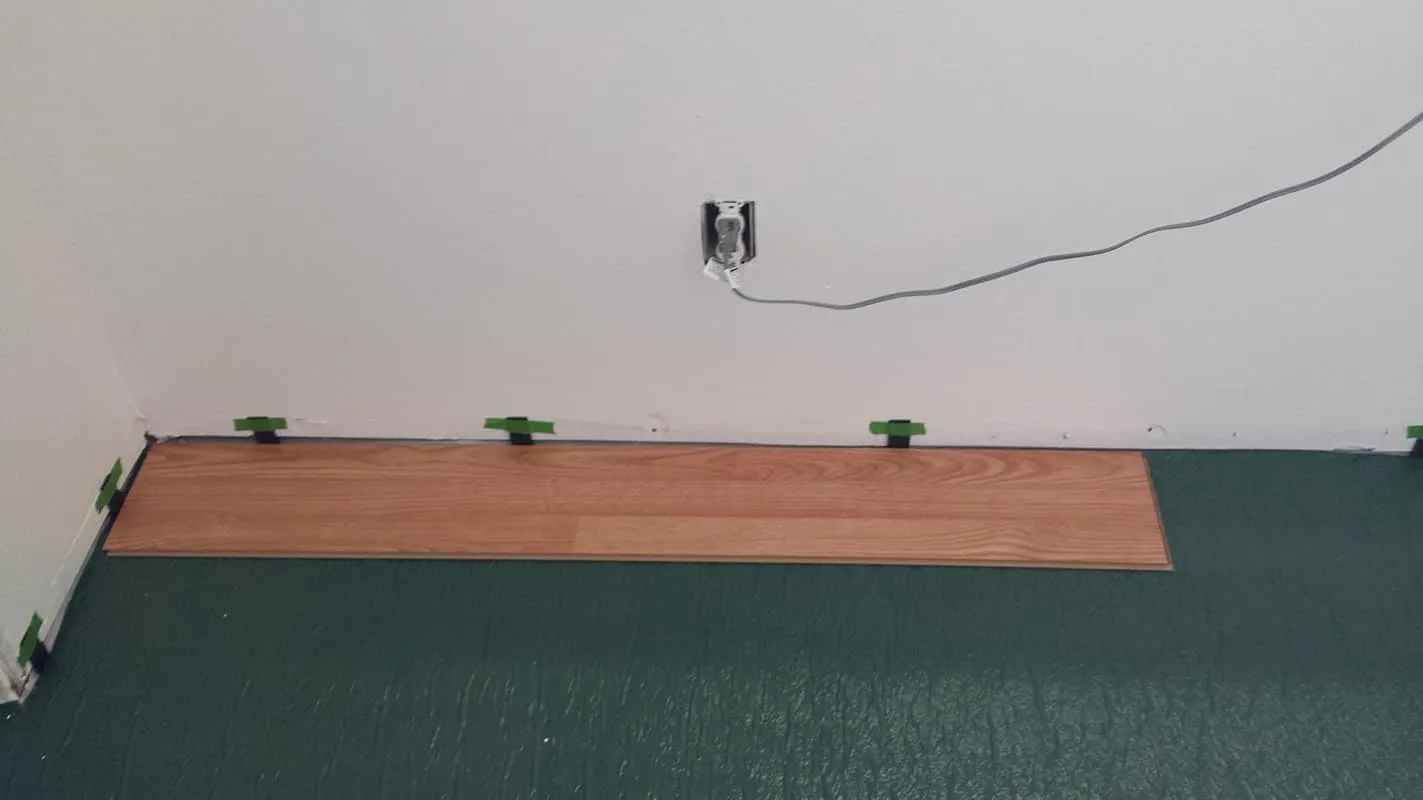

The vapor barrier for laminate flooring with preattached cushioning is exceptional. Unlike other brands that come in unwieldy sheets, this product comes in easy-to-work-with strips that unroll effortlessly. The adhesive on the edges provides a tight seal, ensuring a secure installation.

Working with this vapor barrier is a breeze. It rolls out smoothly and doesn't leave much exposed material to deal with while laying the floor. The tape cover is easy to remove, allowing for seamless sticking down while in place. I even stuck it directly to the concrete, using the tape line of the previous piece as the overlap line. It simplifies the process and saves a significant amount of time.

In terms of quality, this is one of the best 6 mil barrier products available, and it is reasonably priced. The adhesive strip on one side is a brilliant addition that makes overlapping and securing a breeze. It truly is a time-saver.

The durability of this vapor barrier is impressive. It is heavy-duty, comparable to a contractor trash bag. Despite its weight, it is surprisingly easy to work with, making the installation process much smoother.

The only minor inconvenience I experienced was that the end pieces tended to roll up until I had flooring over them. However, this was easily resolved by placing something heavy on top to keep them in place. It's a small issue that wouldn't deter me from purchasing this product again, especially considering its affordable price.

8. Silentguard Laminate Flooring Underlayment – Moisture Protection

QuietWalk is an exceptional underlayment that has proven to be a true lifesaver for my floors. I had installed it in my living room fourteen years ago, and recently faced a plumbing leak that could have caused a major disaster. Thanks to QuietWalk, my floor was protected from any water damage.

The slow leak from behind my refrigerator seeped through the wall and into the living room, unbeknownst to me. It was only when a larger leak occurred that I quickly noticed and took action. Upon inspecting the damage, I was relieved to find that the QuietWalk and underlayment had absorbed all the water. The subfloor and finished floor remained completely unaffected. The vapor barrier of QuietWalk did an excellent job, and the padding efficiently absorbed most of the water. I only had to replace the QuietWalk and underlayment, saving me from a costly and time-consuming floor replacement.

What truly impresses me is that even after fourteen years, the condition of my floating floor remains unchanged. I can still feel the difference between my floor and solid wood, which is a testament to the quality and durability of QuietWalk. My satisfaction with both my floating floor and the performance of QuietWalk goes beyond expectations. It is undoubtedly a worthwhile investment that offers long-lasting protection and superior performance.

Although I am not a professional floor installer, I have used various underlayments in my own home remodels. In the past, I have tried foam underlayment as a means to reduce noise issues while saving some money. However, when my wife and I bought our last house, I wanted to use the best underlayment available, as I had no intention of doing further remodel work. After conducting thorough research, I decided on QuietWalk, and it has exceeded my expectations.

The difference in sound dampening when walking across the floor is incomparable to any other underlayment I have used before. I am extremely pleased with my decision to choose QuietWalk, especially considering the price difference is not significant. The installation process was simple and straightforward, compensating for any slight variation in cost compared to foam underlayment. If I ever decide to install more flooring in my home, I will not hesitate to choose QuietWalk again. It is undoubtedly the best underlayment option available on the market.

FAQs

Are there any alternative methods or products that can be used as a moisture barrier for concrete floors?

Yes, there are alternative methods and products that can be used as moisture barriers for concrete floors. One option is to use epoxy coatings or sealants specifically designed to prevent moisture penetration.

These coatings create a protective layer over the concrete, preventing water vapor from seeping through. Another alternative is to use moisture-resistant underlayments or membranes, such as rubber or plastic sheets, which are installed between the concrete and the flooring material.

These underlayments act as a barrier, preventing moisture from reaching the flooring material. Additionally, there are moisture mitigation systems available that involve applying a liquid or chemical compound directly to the concrete surface.

These compounds penetrate the concrete and form a moisture barrier from within. It's important to consider the specific needs and requirements of your project and consult with a professional to determine the most suitable alternative method or product for your concrete floor moisture barrier.

Are there any specific regulations or requirements for moisture barriers in certain environments or industries?

Yes, there are specific regulations and requirements for moisture barriers in certain environments or industries. These regulations are in place to ensure that proper measures are taken to prevent moisture damage and maintain the integrity of the products or materials being protected.

In industries such as pharmaceuticals, electronics, and food processing, where moisture can have detrimental effects on the quality and safety of the products, strict regulations are enforced. For example, in the pharmaceutical industry, moisture barriers are required to protect medicines from moisture absorption, which can lead to degradation or contamination.

Similarly, in the electronics industry, moisture barriers are essential to prevent corrosion and damage to sensitive electronic components.

Regulations may vary depending on the specific industry, but common requirements for moisture barriers include using materials with high moisture resistance, proper sealing techniques to prevent moisture ingress, and periodic testing and inspection to ensure the effectiveness of the barriers.

It is important for businesses operating in such industries to stay updated with the specific regulations and requirements applicable to their sector to ensure compliance and maintain product quality and safety.

Can a moisture barrier also act as a vapor barrier for a concrete floor?

Yes, a moisture barrier can also act as a vapor barrier for a concrete floor. A moisture barrier is typically installed to prevent groundwater or moisture from seeping into the concrete slab, protecting it from potential damage.

On the other hand, a vapor barrier is designed to prevent the transmission of moisture vapor through the concrete floor, which can cause issues such as mold growth or damage to flooring materials.

In many cases, a moisture barrier can function as a vapor barrier as well, depending on its properties and thickness. However, it is important to note that not all moisture barriers are designed to serve as vapor barriers.

When selecting a moisture barrier for a concrete floor, it is essential to ensure that it meets the necessary specifications for vapor resistance if a vapor barrier is required.

If a moisture barrier does not provide sufficient vapor resistance, it is advisable to install a separate vapor barrier on top of the moisture barrier to effectively control moisture transmission. Consulting with a professional or conducting proper research can help determine the most suitable approach for your specific project requirements.

Can a moisture barrier be applied to an existing concrete floor, or is it only effective during the initial installation?

A moisture barrier can indeed be applied to an existing concrete floor. While it is typically more effective to install a moisture barrier during the initial installation of a concrete floor, it is still possible to retrofit an existing floor with a moisture barrier to mitigate moisture-related issues.

There are different types of moisture barriers available, such as epoxy coatings, sealers, or vapor barriers, that can be applied to the surface of the concrete floor. These barriers create a protective layer that prevents moisture from seeping through the concrete, helping to reduce issues like mold, mildew, and damage to flooring materials.

However, it is important to note that the effectiveness of a moisture barrier on an existing concrete floor may vary depending on the condition of the floor and the severity of moisture-related problems.

It is recommended to consult with a professional contractor or a specialist in concrete flooring to assess the situation and determine the most suitable moisture barrier solution for your specific needs.

How does a moisture barrier prevent moisture from seeping into the concrete floor?

A moisture barrier is a protective layer that prevents moisture from seeping into the concrete floor. It acts as a barrier between the concrete and any moisture present in the ground or surrounding environment.

One common type of moisture barrier is a plastic or polyethylene sheet, which is placed directly on top of the concrete. This sheet prevents moisture from passing through and reaching the concrete. It is crucial to ensure that the moisture barrier is properly installed and sealed to effectively prevent moisture infiltration.

In addition to plastic sheets, other types of moisture barriers include epoxy coatings, rubber membranes, or specialized sealants. These materials create a waterproof barrier that blocks moisture from penetrating the concrete floor.

Moisture can cause various issues such as mold growth, deterioration of flooring materials, and structural damage. By installing a moisture barrier, you can protect the concrete floor and maintain its integrity and longevity.

It is important to consult with professionals in the field to determine the most suitable moisture barrier for your specific needs and conditions.

How often should a moisture barrier be applied or replaced on a concrete floor?

The frequency at which a moisture barrier should be applied or replaced on a concrete floor depends on various factors such as the type of moisture barrier used, environmental conditions, and the level of foot traffic or wear and tear the floor is subjected to.

In general, it is recommended to apply a moisture barrier on a concrete floor during the initial construction or renovation phase. This helps to prevent moisture from seeping through the floor and causing damage to the structure or any materials laid on top of it.

However, if the existing moisture barrier becomes compromised or damaged over time, replacement may be necessary. Signs of a deteriorating moisture barrier include water stains, mold growth, or an increase in humidity levels within the building.

To determine the appropriate timing for reapplication or replacement, it is advisable to consult with a professional contractor or flooring specialist. They can assess the condition of the moisture barrier and provide recommendations based on your specific circumstances.

Regular maintenance and inspections can also help identify any potential issues and ensure the moisture barrier remains effective in protecting the concrete floor.

What are the different types of moisture barriers available for concrete floors?

There are several types of moisture barriers available for concrete floors, each with its own unique characteristics and benefits.

1. Plastic sheeting: This is a common moisture barrier option that involves laying down a plastic sheet between the concrete slab and the flooring material. It helps to prevent moisture from seeping into the flooring, protecting it from damage.

2. Epoxy coatings: Epoxy coatings are a popular choice for moisture control in concrete floors. These coatings create a seamless, waterproof barrier that can withstand high levels of moisture and provide excellent protection against water damage.

3. Vapor barriers: Vapor barriers are specifically designed to control the movement of moisture vapor through the concrete slab. They are typically applied directly to the concrete surface and help to prevent moisture-related issues such as mold growth and flooring damage.

4. Penetrating sealers: Penetrating sealers are used to fill the pores of the concrete, creating a barrier against moisture penetration. These sealers are typically applied to the surface of the concrete and work by chemically reacting with the concrete to form a protective barrier.

It is important to consider the specific needs and requirements of your concrete floor before selecting a moisture barrier. Consulting with a professional or a specialized contractor can help you determine the most suitable option for your specific situation.

What are the signs of a damaged or ineffective moisture barrier for concrete floors?

A damaged or ineffective moisture barrier for concrete floors can exhibit several signs. Firstly, you may notice the presence of moisture or water seeping through the concrete surface. This can manifest as visible dampness or even puddles forming on the floor.

Another indication is the appearance of efflorescence, which is a white powdery substance that forms on the surface due to the migration of moisture and salts. Additionally, if the moisture barrier is compromised, you might observe the development of mold or mildew on the concrete surface.

This can be accompanied by a musty odor. Another sign is the deterioration of any floor coverings or finishes, such as paint or coatings, as moisture can cause them to peel, bubble, or discolor. If you suspect a damaged moisture barrier, it is advisable to consult a professional to assess the situation and recommend appropriate repairs or remedies.

What is a moisture barrier for concrete floors and why is it important?

A moisture barrier for concrete floors is a layer of material that is applied to the surface of the concrete to prevent moisture from penetrating into the floor. It acts as a protective barrier, preventing water vapor and moisture from seeping through the concrete slab.

The importance of a moisture barrier lies in its ability to prevent various issues that can arise due to moisture infiltration. Moisture can cause problems such as mold and mildew growth, which can lead to health concerns and unpleasant odors.

It can also result in the deterioration of flooring materials, such as hardwood or laminate, causing them to warp or buckle.

Furthermore, moisture can weaken the structural integrity of the concrete itself, leading to cracks, spalling, or other forms of damage. By installing a moisture barrier, these potential issues can be minimized or avoided altogether.

In summary, a moisture barrier for concrete floors is important for maintaining a dry and healthy indoor environment, preserving the integrity of flooring materials, and preventing costly repairs and replacements in the future.

What is the cost range for installing a moisture barrier for a concrete floor?

The cost range for installing a moisture barrier for a concrete floor can vary depending on several factors. These factors include the size of the floor area, the type of moisture barrier being used, and the complexity of the installation process.

On average, you can expect to pay between $1 to $3 per square foot for a basic moisture barrier installation. This price typically includes the cost of materials and labor. However, it is important to note that this is just a general estimate and prices can vary significantly.

If you are considering installing a moisture barrier for your concrete floor, it is recommended to get multiple quotes from different contractors. This will allow you to compare prices and choose the best option that fits your budget.

Additionally, it is advisable to consult with a professional contractor who can assess your specific needs and provide a more accurate cost estimate based on your unique situation.