I Tested And Reviewed 10 Best Water Based Polyurethane For Floors (2023)

Choosing the best water based polyurethane for your floors is an important decision that requires some research and consideration. With so many options on the market, it can be overwhelming trying to determine which product will provide the right finish and protection for your specific flooring needs. As you shop around, here are some key factors to keep in mind.

First, think about the type of floors you need to coat. Whether you have hardwood, laminate, or concrete floors, you'll want to find a polyurethane formula designed specifically for that surface material. Consider the amount of traffic and wear your floors receive as well. High-traffic areas may benefit from polyurethanes with maximum durability.

You'll also want to decide between a gloss, satin, or matte finish. Gloss polyurethanes offer a smooth, shiny look that enhances wood grain. Satin finishes provide a soft subtle sheen. Matte options give a more natural, low-luster appearance. So factor in your personal style preferences when selecting a finish.

How easy is the polyurethane to apply and care for? Seek out water-based options that go on smoothly and are low odor. Quick dry times are ideal to minimize downtime. Some formulations also contain UV blockers to better resist fading and yellowing over time. Review application tips and maintenance requirements before purchasing.

Investing in the best water based polyurethane for your floors takes some careful evaluation. But taking the time to research and compare products will ensure you achieve the look, performance and durability your floors need. Consult manufacturer websites for product specifications and talk to sales associates for guidance. With the right polyurethane choice, you'll be set with beautiful, protected floors for years to come.

10 Best Water Based Polyurethane For Floors

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for providing a water-based, durable and satin finish to various surfaces.

|

|

||

|

2

|

The product is ideal for providing a water-based, satin finish on various surfaces such as wood furniture or flooring.

|

|

||

|

3

|

The product is ideal for providing a clear and durable satin finish to interior floors.

|

|

||

|

4

|

The product is ideal for providing a clear, warm satin finish to wood surfaces.

|

|

||

|

5

|

The product is ideal for providing a glossy finish to wood surfaces, such as furniture or flooring.

|

|

||

|

6

|

The product is ideal for applying a clear and semi-gloss finish to wooden floors.

|

|

||

|

7

|

The product is ideal for providing a durable, water-resistant clear finish on various surfaces.

|

|

||

|

8

|

The product is ideal for providing a glossy protective finish on floors, offering waterborne durability and enhancing their appearance.

|

|

||

|

9

|

The product is ideal for providing a durable and shiny finish on various wood surfaces.

|

|

||

|

10

|

The product is ideal for providing a glossy finish and protecting wooden surfaces from various elements and wear.

|

|

1. Varathane 200261h Water-Based Ultimate Polyurethane, Half Pint, Satin Finish

I recently purchased this water-based polyurethane for a DIY project, and I must say, I am thoroughly impressed. I used it on an unfinished Gerton tabletop from Ikea, and the results were fantastic. The application process was a breeze, requiring just a light sanding and wipe down before using a brush to apply the polyurethane. The small can surprisingly contained enough product for three coats on the table and a small end table, with some left over.

One of the standout features of this polyurethane is its ability to dry perfectly clear. Despite initially appearing milky when applied, as stated on the can, it dried to a crystal-clear finish. This is particularly beneficial for projects where maintaining the original color is important.

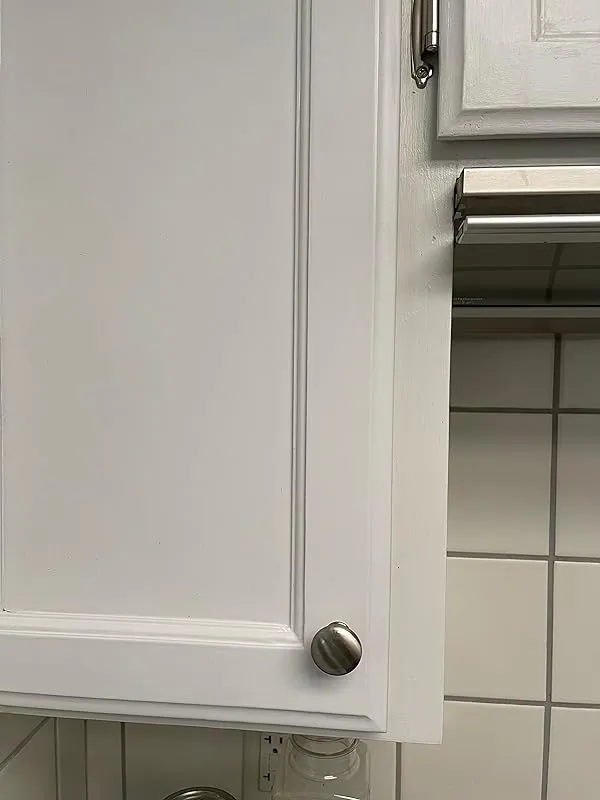

In addition to using it on my tabletop, I also applied this matte varathane to my kitchen cabinets. The varathane provided a beautiful finish, with no yellowing, even on white surfaces. This is a common concern with white paint, but I can confidently say that this polyurethane delivered on its promise of preserving the color integrity.

Furthermore, I decided to revive an old wooden end table using this polyurethane. After sanding the faded surface and applying some boiled linseed oil for restoration, I chose this satin-sheen polyurethane to add the final touch. The water-based formula made it incredibly easy to work with and clean up afterward. The small container size was perfect for my needs, and I appreciated the cautionary advice about potential lid drying.

The satin sheen provided by this polyurethane was the perfect match for the existing finish on most finished wood. It enhanced the natural beauty of the wood without being overly glossy or dull. The result was a lovely, rejuvenated end table that looked vibrant and attractive.

2. Varathane 200241h Water-Based Ultimate Polyurethane, Quart, Satin Finish

I am extremely pleased with the outcome of using this chalk paint. I wanted to brighten up my room, so I decided to paint my dresser and laundry room cabinets with the linen white chalk paint by Rustoleum. I used a primer before applying the chalk paint and found that using a foam roller gave a better finish compared to using a brush. Although there were some visible brush strokes on the dresser, they were not noticeable from a distance. I also used a polycrylic on the drawers and wax on the dresser to seal the paint. Personally, I prefer the look and feel of the polycrylic and plan on using it for future projects.

The application process was easy, and I appreciated that the paint dried quickly, allowing me to complete the project in a day. I only needed two quarts of paint for my large table, but had to find an alternative option for the table legs. After four weeks of regular use and with small kids pounding on it, the finish has proven to be quite durable. I have not experienced any moisture or heat rings from glasses or mugs placed directly on the table. The satin finish is beautiful and leaves a silky smooth texture. What's even better is that clean up was a breeze, and I didn't need to use any stinky mineral spirits.

3. Satin Diamond Floor Polyurethane By Rust-Oleum: Crystal Clear

I have been using various water-based and oil-based polyurethanes for many years, but I must say that this particular product is the best in terms of leveling, ease of handling, and durability. It dries incredibly hard, allowing me to poly a pantry shelf and place cans on it the very next day without any indentation or sticking. I now exclusively use this product for all my flooring projects because it provides a rock-hard finish.

I recently used it on my living room floor, which is a 60-year-old original floor, and the results are fantastic. Despite having three energetic pit bulls running around, the finish is holding up perfectly fine. Another great feature of this product is that it has absolutely no odor, making the application process much more pleasant. With just one gallon, I was able to apply three coats on a 17.5 foot by 19.5-foot room using a paint roller and a dry paint brush. I applied it on oil-stained paper floors over concrete, and after over a month, it still looks beautiful.

I must mention that it's important to apply thin coats to avoid cloudiness. In one area where we accidentally applied it too thick, it turned out cloudy instead of clear. However, the rest of the room has a clear and beautiful finish. Despite the product not being recommended for vinyl, I took the risk and applied three coats over my painted grey vinyl floor, and it turned out wonderfully. It made my floor shine like new.

As a professional furniture and cabinet maker with over 30 years of experience, I have used top-of-the-line spray equipment and applied a wide range of wood finishes. Surprisingly, this Varathane water-based floor finish has proven to be tactile and durable. I am able to achieve excellent results with minimal effort. Whether I'm finishing cabinets or furniture using spray equipment in the shop or using a brush on-site, this product consistently delivers a high-quality and long-lasting finish. I'm truly impressed and always make sure to have this product on hand.

4. Minwax Water Based Oil-Modified Polyurethane, Warm Satin, Clear, 1 Gallon

I recently purchased the Minwax Satin Water Based Oil Modified Polyurethane and I have to say, I am quite impressed with this product. After reading some negative reviews, I was a bit hesitant, but I found that those reviews didn't do justice to the quality of this polyurethane.

First and foremost, it's important to follow the instructions provided. The floors should be lightly sanded between coats, and it clearly states not to use steel wool. By following these guidelines, I had no issues with the application process. Additionally, working in small areas is recommended to ensure a smooth and even finish. Trying to cover a large area at once can lead to potential issues.

One of the standout features of this product is the fast drying time. I found it to be incredibly convenient, especially when working on projects that require multiple coats. The quick drying time allowed me to move on to the next step without too much waiting around. Plus, the smell of this water-based polyurethane is much milder compared to regular oil-based ones, making it more pleasant to work with.

I used this polyurethane as a top coat on foam core board, which I had painted with a faux wood grain technique using both water-based and oil-based stains. To my delight, this water-based polyurethane adhered equally well over both types of stains. It also dried super fast, which was crucial for my foam board project, as it tends to warp if exposed to excess moisture. In comparison to the Minwax Polycrylic, I found this water-based polyurethane to be superior in terms of drying time and ease of use.

While some may argue that it may not be as durable as the water-based Polycrylic under extreme conditions, for craft projects like mine, it was the ideal choice. The multiple steps, coats, and dry time in between were made much easier with this polyurethane. Minwax truly hit a home run with this product.

I would like to add a helpful tip for those who are new to this product. I recommend using a foam brush for application. Despite being a bristle brush user myself, I found that the foam brush provided the best results. It may be due to the fast drying time or the combination of water and oil in the product, but a cheap foam brush worked wonders for me. If you prefer, a spray gun could also be a good option. Just remember to work efficiently and avoid brushing over areas that have already been coated, as it dries quickly.

5. Varathane 200041h Water-Based Ultimate Polyurethane, Quart, Gloss Finish

The Varathane water-based crystal clear polyurethane is a highly recommended choice for finishing exotic wood projects. With its wide range of benefits and ease of use, it proves to be a reliable option for both beginners and experienced woodworkers.

One of the standout features of this varnish is its safety and environmental considerations. Unlike solvent-based finishes that can be flammable and pose risks, the water-based formula eliminates these concerns, making it suitable for use in various settings, including home workshops.

Durability is another key aspect of the Varathane polyurethane. The reviewer mentions using it on a rat cage for 20 years, where it withstands heavy punishment from urine, food spills, and regular cleaning. The varnish proves to be resilient, easily cleaned with water and a damp paper towel, and even withstanding scrubbing with isopropyl alcohol. This level of durability is essential for projects that require resistance to wear and tear.

The ease of application is also highlighted by the reviewer. They have successfully used both brushes and foam rollers to apply the varnish, achieving excellent results. Even when deviating from the recommended application methods, such as using a foam roller instead of a brush, the varnish adheres well and dries crystal clear without any bubbles or imperfections.

In addition to wood projects, the Varathane polyurethane can also be used as a top coating over primer. The reviewer mentions using it on built-in shelving and inside drawers to solve issues with powdery surfaces and peeling paint. The varnish provides a smooth and slick finish, making it a suitable option for areas that require easy sliding, such as drawers.

6. Varathane 230131 Crystal Clear Floor Finish, Semi-Gloss 1 Gallon

I recently purchased this product and I must say, it is truly a great product. The application process was incredibly easy and convenient, as I was able to re-coat after just two hours. The semi-gloss finish was exactly what I was looking for on my floors.

One thing I noticed is that the product goes further than what is stated. I ended up over-ordering, but was pleasantly surprised to find that I could do three coats on my 450sqft floor with just a little over a gallon. This is definitely a cost-effective option.

I used a synthetic foam pad on a pole to apply the product. I simply dumped a small puddle and spread it with the grain, slightly overlapping the previous pass. However, if I could change one thing, I would have lightly sanded after the first coat. The water-based formula did raise the grain of my old oak floors slightly, but I didn't take the extra time to do this step. It's not a major issue, but it didn't give me the super sleek and smooth finish that some people may prefer.

It's been about a month since I applied the product and so far, the floors are holding up great with just three coats. If I weren't selling my house soon, I would have gone ahead and done a fourth coat. Overall, I would highly recommend this product and will definitely use it again in the future.

In addition to its performance on floors, it's worth noting that this product can be used on other wooden surfaces as well. I have used it on the wood supporting a mattress in a bed, shelves, desks, and various handmade wooden devices, and it has provided a great finish in all of these applications.

The smell of this product is on the weaker side compared to other varnishes, which is a plus. It brushes on smoothly and flows really nicely. I was able to completely remove it from my brush with just soap and water, making cleanup a breeze. I will definitely be buying this product again for any non-water contact wood projects.

When applying the finish, I usually scrape the intended area and wipe it down with a damp cloth if necessary. The first coat may be a bit rough due to the wood fibers bending when they come into contact with the finish. However, a few passes with a cabinet scraper can create a smooth foundation for the second coat, which is usually very smooth. I rarely need to sand or scrape after the second coat, especially for hardwoods. For softwood like pine, I usually apply 4-5 coats. I prefer using a brush over foam brushes, as I found that foam brushes tend to leave too many bubbles on the surface of the finish. The brush is also easy to clean with soap and water.

Lastly, I have found that this product stores well in plastic containers. It may be worth experimenting with polyethylene containers for easier sealing and unsealing compared to the metal can.

7. Rust-Oleum 250241h Ultimate Spar Urethane Water Based, Quart, Satin Finish 32 Fl Oz (Pack Of 1)

I recently came across this product and it has quickly become one of my favorites, although not for its original intended use. Initially, I wanted to use it as a clear coat for my sailboat's countertops, as I needed UV resistance due to the boat being in Florida. However, when I applied it to a light, uniform plastic surface, I noticed that it left very tiny brush strokes that were barely visible but still present, depending on the light. This wasn't what I was looking for.

However, I decided to try the product on wood and the results were fantastic. Unlike on the plastic surface, there were no brush strokes whatsoever when applied to wood. This was perfect for me. I particularly love that it is crystal clear and doesn't alter the natural color of the wood. I ended up using it on my teak and holly sole inside the boat, even though it is not recommended for flooring. There are several reasons why I made this decision:

1. Easy application: The product is incredibly easy to apply.

2. Fast drying: It dries incredibly fast, especially in the Florida climate. I was able to re-coat every 5 minutes.

3. No sanding required: Unlike other clear coats, there is no need for sanding.

4. Enhances the wood grain: It beautifully enhances the natural grain of the wood, similar to when the wood is wet.

5. Seals and waterproofs the wood: It effectively seals and waterproofs the wood.

6. No yellowing: Unlike teak oil or varnish, this product does not yellow the holly wood, which was originally white.

The end result was fantastic. I was able to complete the project on my 30-foot boat in less than an hour. Additionally, if I ever need to reapply in the future, it can be done easily and quickly. While it may not have a lifespan of 10 years, it is affordable, fast, easy to use, looks great, and requires no maintenance, sanding, or mess when reapplying. It provides excellent protection for my teak and holly sole. I highly recommend this product to any boater who wants an easy, hassle-free, and guaranteed perfect result without any strokes, bubbles, or issues. It truly is a product to love.

I initially came across this product while searching for an outdoor-rated sealant that wouldn't add a yellow tint and wouldn't have a glossy finish. To my delight, this product turned out to be perfect. It is incredibly easy to apply and dries completely clear. Although I thought I preferred matte finishes, the satin finish provided by this sealant took my projects to the next level. The attached photos showcase a chair, bench, and plant stand before and after three coats of the spar urethane had been applied and dried. I noticed that the sealant helped to draw out and enhance the color of the wood, resulting in a slightly darker tone. It is worth mentioning that the chair may have had an additional coat of stain in the after photo, and the bench in the after photo was taken on a cloudy day instead of a sun-soaked day like the first photo.

While it is still too early to determine its long-term protection capabilities, after a month of exposure to the Denver sunshine and 90+ degree days, the wood still looks as good as it did originally. Although I haven't experienced much rain in this dry climate, I have noticed that water sits on the surface of the wood until it evaporates and isn't absorbed into it. Overall, I am extremely satisfied with this product and its performance.

8. Rust-Oleum 230031 Varathane Gallon Gloss Waterborne Diamond Floor Finish 1 Gallon

In contrast to some previous reviews, I have personally found that the odor of this product is minimal and does not require opening windows for ventilation. Additionally, the drying time for each coat on my log home wood floors was impressively quick, taking only an hour to touch.

I found this product to be very easy to work with, as it applies smoothly and dries crystal clear as advertised. The results on my painted countertop, as well as in between layers of mica powder, were beautiful with no issues of cloudiness or bubbling. What's more, this topcoat does not become cloudy or tacky when water is spilled on it, making it a fantastic choice for a countertop.

Although I cannot compare this product to other options for wood floors, I was pleased enough with the initial gallon that I purchased two more. It was easier to apply and had a much less overpowering odor compared to the oil-based varnish I had previously used. While I initially used a lambs wool applicator, I found that it would catch on small edges of my floor and leave fibers. However, I had better success with a synthetic applicator pad designed for staining decks.

While this product effectively protects the floor, it does have a drawback in that it accentuates cracks, dents, and imperfections. In my case, I was covering a cement garage floor that I had just repainted. The protective layer provided by this topcoat was noticeable, as the previous paint had been easily scratched and left marks when walked over. However, the gloss of the topcoat brought attention to all the cracks and dents, which were previously hidden by a matte black paint. Therefore, I would not recommend using this product on a garage floor or any floor with significant blemishes that you do not want to be brought to light.

9. Varathane 200141h Water-Based Ultimate Polyurethane, Quart, Semi-Gloss Finish

The Rust-Oleum Varathane Polyurethane is a game-changer when it comes to finishes. As a former owner of a custom woodwork manufacturer, I can confidently say that this product surpasses all other options in the market. It outperforms oil-based products with its higher solids content and exceptional durability, requiring fewer coats.

One of the standout features of this polyurethane is its self-leveling properties. When applied over any wood surface, it creates a perfectly clear finish that enhances the natural beauty of the wood. The quick drying time and ease of sanding make it a joy to work with, saving both time and effort.

Clean-up is a breeze with this product. Brushes and spills can be easily cleaned with just water, leaving no residue behind. The brushes remain supple and clean with minimal cleaning effort. This water-based polyurethane is a significant improvement over its oil-based counterparts, offering a superior finish without any disappointment.

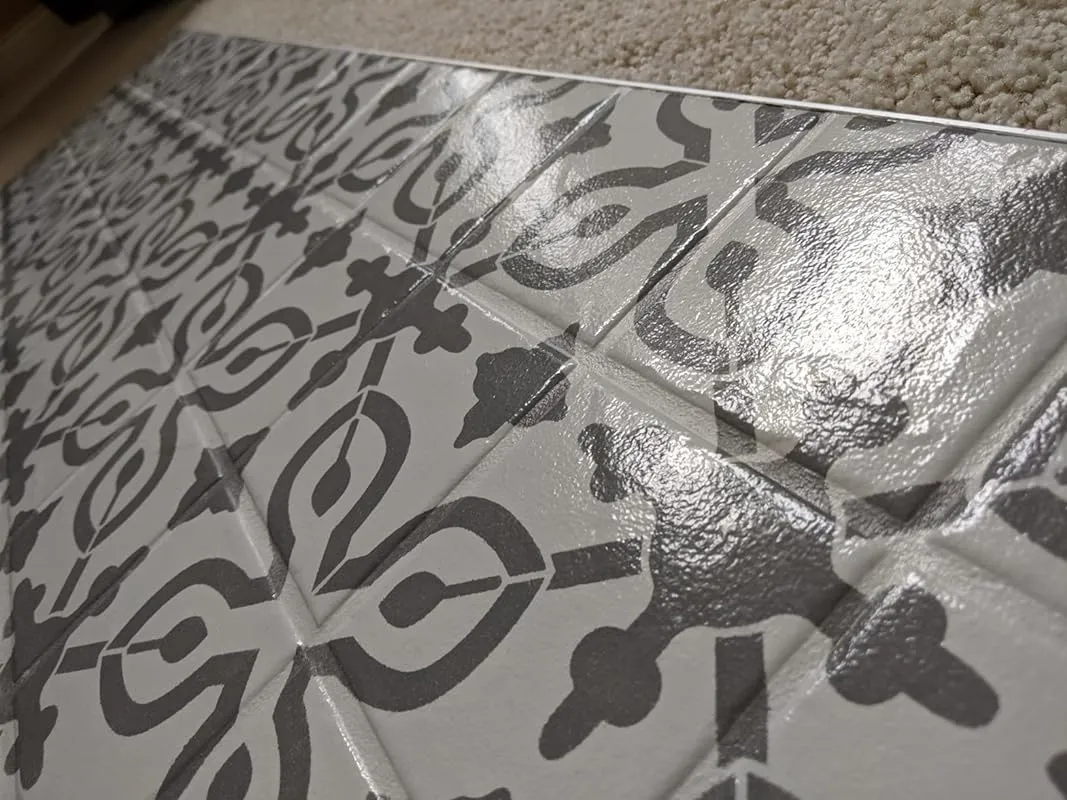

For those who may be new to using this product, there is no need to be nervous. It is user-friendly and can be applied with a foam roller or brush. In a recent project, I used a white 4" foam roller to apply three coats over painted and stenciled fireplace tile. The result was a beautiful sheen that provided excellent protection. Although it is too early to determine the long-term durability, initial impressions are positive.

What sets this Rust-Oleum polyurethane apart from other clear finishes is its ability to maintain a truly clear appearance. Even the slightest hint of yellow can ruin a piece of furniture, but with this product, that concern is eliminated. It delivers on its promise of a crystal-clear finish that enhances the natural beauty of the wood.

In my experience, having used various polyurethanes over the years, this Rust-Oleum Varathane Polyurethane stands out as the best. It glides on smoothly and effortlessly, with minimal odor, and dries quickly to a hard, non-sticky finish. Clean-up is a breeze, as water is all you need. Overall, I am thoroughly impressed with this product and highly recommend it.

While this polyurethane may not be as hard or durable as epoxy, it is still a great option, especially considering its affordability and ease of use. I used it to protect a stick-on laminate coating on my kitchen counter. Initially, I applied light coats, but they didn't provide enough protection. I then poured and spread it with a foam brush, hoping for self-leveling properties similar to epoxy. While it did level out for the most part, there were some pooling spots that were slightly softer than the rest of the coating. However, it did dry to a crystal-clear finish, making it a viable alternative to epoxy.

10. Varathane 200061h Water-Based Ultimate Polyurethane, Half Pint, Gloss Finish

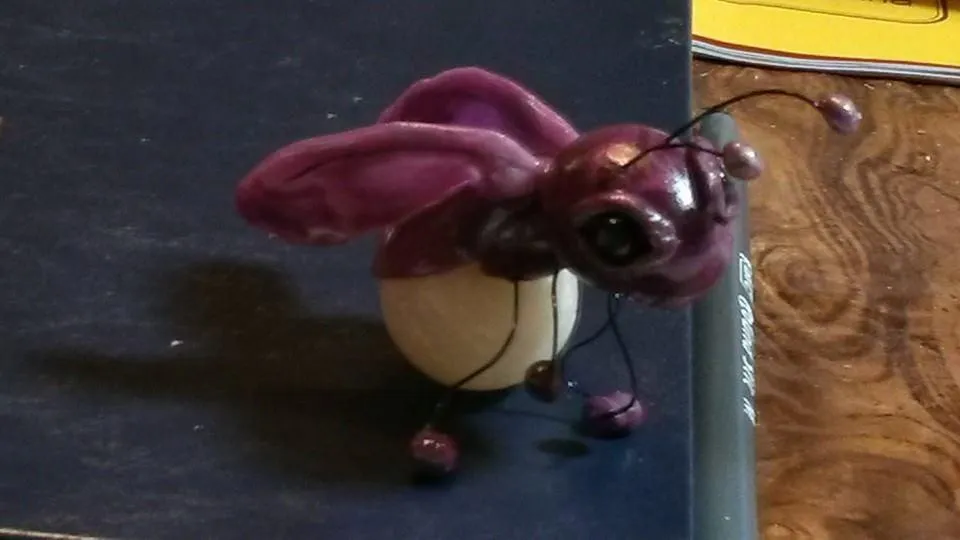

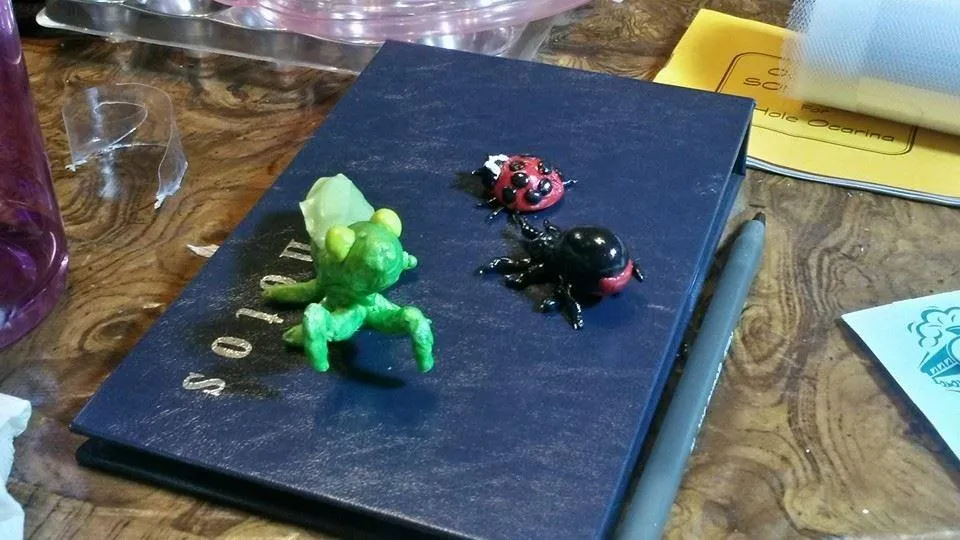

The Varathane Polyurethane is a highly recommended varnish for polymer clay projects. It comes in a small can, but a little goes a long way, and one coat is usually sufficient. The consistency is just right, not too thin or too thick.

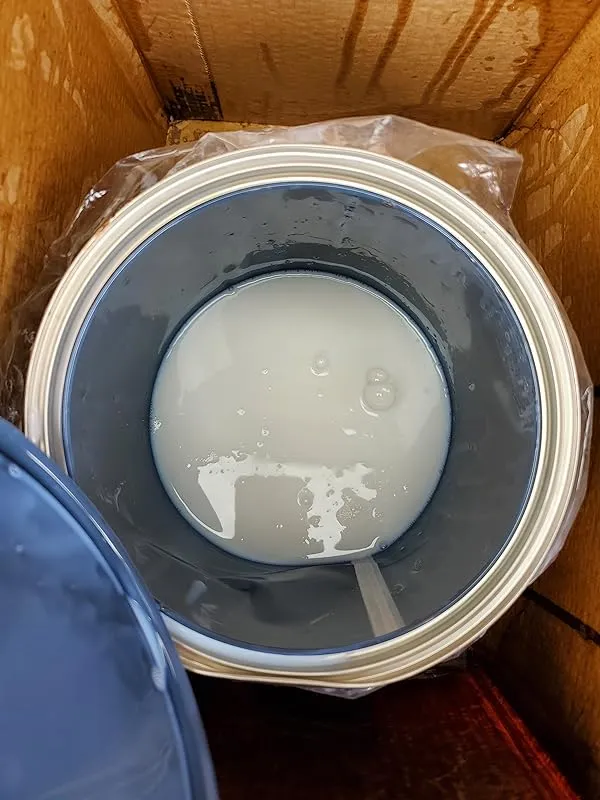

Initially, the varnish may appear white and cloudy in the can, but it dries clear. It is important to follow the instructions and stir the varnish instead of shaking it. This ensures optimal results.

One of the standout features of this product is its fast-drying nature. It dries quickly, leaving a clear and glossy finish on polymer clay items. Unlike other glazes, it does not become sticky or develop cracks over time. It is a durable and long-lasting solution.

Furthermore, the Varathane Polyurethane has a slight iridescence to it, which aids in the application process. This characteristic allows users to easily see where they have applied the varnish, ensuring an even coating. Additionally, it serves as an indicator of the drying progress. If the coating is not completely clear, it is still wet and should not be touched.

Multiple coats of this varnish can be applied to achieve a beautiful glass-like shine on polymer clay charms. It not only enhances the appearance but also acts as a reliable sealant, keeping the pieces intact and preventing powders or other embellishments from rubbing off.

It is worth mentioning that if the varnish appears too thick for application, adding a bit of water can restore its consistency.

FAQs

Are there any special maintenance requirements for floors finished with water-based polyurethane?

Yes, there are some special maintenance requirements for floors finished with water-based polyurethane. While water-based polyurethane is known for its durability and resistance to wear, it still requires regular cleaning and care to maintain its appearance and longevity.

Firstly, it is important to keep the floor free from dirt, dust, and debris. Regular sweeping or vacuuming with a soft brush attachment will help prevent scratches and abrasions. Avoid using abrasive cleaners or rough scrubbing pads, as these can damage the finish.

Secondly, it is recommended to use a pH-neutral cleaner specifically designed for polyurethane-finished floors. Avoid using harsh chemicals or ammonia-based cleaners, as they can dull or strip the finish.

Instead, opt for a mild detergent mixed with water, and use a damp mop or cloth to clean the floor. Make sure to wring out the mop or cloth well to avoid excessive moisture on the floor.

Lastly, it is advisable to place mats or rugs at entryways to trap dirt and prevent it from being tracked onto the floor. Use felt pads or furniture coasters under heavy furniture to prevent scratches and indentations.

By following these maintenance guidelines, you can ensure that your water-based polyurethane finished floors retain their beauty and durability for years to come.

Are there any specific brands or products that are highly recommended for water-based polyurethane on floors?

When it comes to water-based polyurethane for floors, there are several highly recommended brands and products that you can consider. One popular brand is Bona, known for its high-quality floor finishes.

Bona Mega and Bona Traffic are two of their top products that are often recommended for their durability and performance.

Another trusted brand is Minwax, which offers a range of water-based polyurethane options for floors. Their products are known for their ease of application and excellent protection.

General Finishes is also a reputable brand that offers water-based polyurethane finishes for floors. Their High-Performance Water-Based Topcoat is often recommended for its durability and resistance to yellowing.

Ultimately, the choice of brand and product may depend on factors such as your specific floor type, desired finish, and personal preferences. It is always recommended to read product reviews, consult with professionals, and follow manufacturer guidelines for the best results.

Can water-based polyurethane be applied over oil-based polyurethane on existing hardwood floors?

Yes, water-based polyurethane can be applied over oil-based polyurethane on existing hardwood floors. However, there are a few important considerations to keep in mind.

Firstly, it is crucial to ensure that the existing oil-based polyurethane is completely dry and properly cured before applying the water-based polyurethane. This may require allowing the oil-based polyurethane to cure for several days or even weeks, depending on the specific product and environmental conditions.

Secondly, it is recommended to lightly sand the surface of the existing oil-based polyurethane to create a rough texture that will allow better adhesion for the water-based polyurethane. This can be done using fine-grit sandpaper or a sanding screen.

Additionally, it is important to clean the surface thoroughly to remove any dust or debris before applying the water-based polyurethane. This will ensure a smooth and even finish.

Lastly, it is advisable to test a small, inconspicuous area before applying the water-based polyurethane to the entire floor. This will help determine if there are any compatibility issues or unwanted reactions between the two types of polyurethane.

Overall, while it is possible to apply water-based polyurethane over oil-based polyurethane on existing hardwood floors, proper preparation and testing are essential for a successful outcome.

Can water-based polyurethane be used on other types of flooring, such as laminate or engineered wood?

Water-based polyurethane can typically be used on laminate and engineered wood flooring. However, it is important to check the manufacturer's recommendations and guidelines for the specific flooring material you have.

Some laminate and engineered wood floors may have specific requirements for finishing products, and using the wrong type of polyurethane could potentially damage the floor or result in an undesirable finish.

It is always best to follow the manufacturer's instructions to ensure the best results and to avoid voiding any warranties. If you are unsure, it is recommended to consult with a flooring professional who can provide specific advice based on your flooring type and condition.

Does water-based polyurethane for floors have a strong odor during application and how long does it take to dissipate?

Water-based polyurethane for floors typically has a milder odor compared to oil-based polyurethane. While it does have a noticeable smell during application, it is generally not as strong or overpowering. The intensity of the odor can vary depending on the brand and specific product used.

In terms of how long it takes for the odor to dissipate, it depends on various factors such as ventilation, temperature, and humidity levels. Generally, water-based polyurethane odors tend to dissipate within a few days to a week.

Proper ventilation, opening windows, and using fans can help speed up the process of odor reduction.

If you are sensitive to smells, it is advisable to avoid staying in the area immediately after application and allow more time for the odor to disperse. Additionally, using low-odor or odorless water-based polyurethane products may be a good alternative if you are concerned about the smell.

Does water-based polyurethane for floors provide UV protection to prevent fading and discoloration?

Yes, water-based polyurethane for floors can provide UV protection to some extent, but it is important to note that the level of UV protection may vary depending on the specific product and brand. Water-based polyurethane coatings typically contain additives that help to block or absorb UV rays, which can help prevent fading and discoloration of the floor surface.

However, it is essential to choose a high-quality water-based polyurethane that specifically mentions UV protection in its product description and specifications. Additionally, it is recommended to apply multiple coats of the polyurethane to enhance the UV protection and ensure better durability.

Regular maintenance and reapplication of the polyurethane may also be required over time to maintain the UV protection and prolong the life of the floor finish. If you are concerned about UV protection for your floors, it is advisable to consult with a professional flooring expert or the manufacturer of the polyurethane product for specific recommendations and guidance.

How long does water-based polyurethane typically last on hardwood floors?

Water-based polyurethane typically lasts on hardwood floors for about 5 to 10 years, depending on various factors such as the amount of foot traffic, the quality of the polyurethane used, and how well the floors are maintained.

It is important to note that water-based polyurethane tends to have a shorter lifespan compared to oil-based polyurethane, which can last up to 15 years or more. However, water-based polyurethane offers several advantages such as faster drying time, low odor, and easier cleanup.

To maximize the lifespan of water-based polyurethane on hardwood floors, it is recommended to follow proper maintenance practices like regularly cleaning the floors, avoiding excessive moisture, and using protective pads on furniture.

Additionally, recoating the floors every few years can help rejuvenate the finish and prolong its durability.

Is water-based polyurethane as durable as oil-based polyurethane for floors?

Water-based polyurethane is a popular choice for floor finishes due to its many advantages. While both water-based and oil-based polyurethane provide durability, there are some differences between the two.

Water-based polyurethane offers excellent durability and can withstand everyday wear and tear. It forms a strong protective layer on the floor surface, guarding against scratches, stains, and moisture damage.

However, it may not be as durable as oil-based polyurethane in high-traffic areas or under extreme conditions.

Oil-based polyurethane, on the other hand, is known for its exceptional durability. It creates a hard and resilient finish that can handle heavy foot traffic and resist abrasions. It is particularly recommended for floors in commercial settings or areas prone to excessive wear and tear.

Ultimately, the choice between water-based and oil-based polyurethane depends on your specific needs and preferences. If you prioritize environmental friendliness, quick drying time, and easy application, water-based polyurethane is a suitable option.

If maximum durability is your primary concern, especially in high-traffic areas, oil-based polyurethane may be a better choice.

What is the recommended application process for water-based polyurethane on floors?

The recommended application process for water-based polyurethane on floors involves several steps to ensure a successful and long-lasting finish. Here is a general outline of the process:

1. Preparing the surface: Start by thoroughly cleaning the floor to remove any dirt, dust, or debris. Sand the floor lightly to create a smooth surface and remove any existing finish. Vacuum or sweep the floor again to remove any remaining dust.

2. Applying the first coat: Use a high-quality synthetic bristle brush or a lambswool applicator to apply the water-based polyurethane evenly across the floor. Work in small sections, applying the product in long, even strokes along the grain of the wood.

Avoid over-applying to prevent streaks and pooling.

3. Drying and sanding: Allow the first coat to dry completely according to the manufacturer's instructions. Once dry, lightly sand the floor using a fine-grit sandpaper or sanding screen to smooth out any imperfections or raised wood fibers. Vacuum or sweep the floor again to remove the sanding dust.

4. Applying subsequent coats: Repeat the application process for additional coats, typically two to three coats are recommended. Make sure to lightly sand between coats to promote adhesion and achieve a smooth finish.

5. Final drying and curing: Allow the final coat to dry and cure according to the manufacturer's instructions. This process can take several days, so it's important to avoid foot traffic and furniture placement during this time.

Remember to read and follow the specific instructions provided by the manufacturer of the water-based polyurethane you are using. It's also a good idea to test the product in a small inconspicuous area before applying it to the entire floor to ensure compatibility and desired results.

What is water-based polyurethane for floors and how does it differ from oil-based polyurethane?

Water-based polyurethane for floors is a type of finish that is used to protect and enhance the appearance of hardwood floors. It is made up of a combination of synthetic resins and water, which acts as a carrier for the resins.

One of the key differences between water-based and oil-based polyurethane is the drying time. Water-based polyurethane dries much faster than oil-based, typically within a few hours. This makes it more convenient for those who want to minimize downtime during the refinishing process.

Another difference is the odor and toxicity. Water-based polyurethane has a milder odor and lower toxicity compared to oil-based, which can emit strong fumes and require proper ventilation during application.

In terms of appearance, water-based polyurethane tends to have a clear and transparent finish, while oil-based polyurethane can add a slight amber or golden tone to the wood.

Lastly, water-based polyurethane is known for its durability and resistance to yellowing over time. It is also less prone to cracking and peeling, making it a popular choice for high-traffic areas.

In summary, water-based polyurethane offers faster drying time, lower odor and toxicity, clear finish, and enhanced durability compared to oil-based polyurethane.