I Tested And Reviewed 7 Best Water Based Screen Printing Ink (2023)

When it comes to screen printing, having the right equipment and materials is crucial for producing high-quality prints. One of the most important supplies is choosing the best water-based screen printing ink for your needs. With so many options on the market, deciding on the right ink can be overwhelming.

Before purchasing water-based screen printing inks, there are a few key factors you should consider. First, examine the fabric you'll be printing on. Is it 100% cotton, a cotton blend, or polyester? The ink's viscosity and compatibility with the fabric is essential for crisp, vivid images that don't crack or fade after washing. Next, determine the level of opacity you require. Do you need a high opacity ink to print on dark garments or will a lower opacity work for printing on light colors?

Here are a few questions to ask yourself when evaluating water-based screen printing inks: Does the ink need to be air dry or heat cured? What is the ink's durability after washing? Does it contain harmful VOCs or is it an eco-friendly formula? Do you need a variety of colors or just basic primary colors? Getting the answers to these questions will help narrow your search for the ideal water-based ink.

Finding the best water-based screen printing ink for your needs takes research and testing. But with the right ink choice, you'll be equipped to produce eye-catching prints with professional results. Let the quality of your prints speak for itself.

7 Best Water Based Screen Printing Ink

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for printing on fabric and shirts using a screen printing kit.

|

|

||

|

2

|

The product is ideal for screen printing on silk screens and fabric using plastisol or water-based inks.

|

|

||

|

3

|

The product is ideal for screen printing t-shirts and creating silkscreen prints.

|

|

||

|

4

|

The product is ideal for screen printing on fabric materials.

|

|

||

|

5

|

The product is ideal for screen printing on various fabrics, providing a super opaque white color.

|

|

||

|

6

|

The product is ideal for screen printing designs onto various fabrics and surfaces.

|

|

||

|

7

|

The product is ideal for screen printing on fabrics, providing a super opaque white color with water-soluble properties.

|

|

1. Ecotex® Snow White Fabric Ink – 16oz. Pint

After trying various water-based whites, I can confidently say that this ink is the best. Its consistency and coverage are unbeatable, surpassing even Comet white and Permaset Supercover. As someone who prints a large order of garments without a sophisticated setup, I find that four passes of this ink is usually enough to cover black fabric without the need for print-flash-print. Additionally, it has good cure times and wash fastness, making it highly recommended.

As an amateur home screen printer, I found this water-based ink to be excellent. It offers good coverage, dries easily, and has a nice consistency. All of this comes at a reasonable price, making it a product I will definitely purchase again.

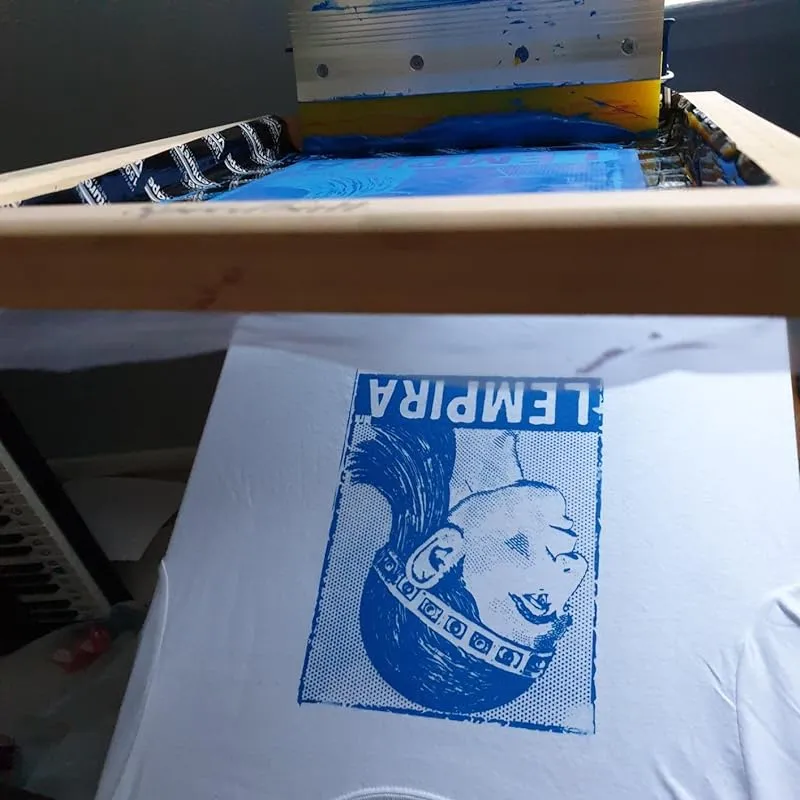

I had great results when I mixed this ink with a 5-6% discharge additive. After running it through our dryer at 300 degrees for 90 seconds, the colors turned out bright with a soft hand after washing. To improve consistency, I also added a bit of water to the ink. The image shown in the review was printed on a black cotton tee.

I had a positive experience with this product. I previously tried using Speedball ink, but it kept cracking despite following the correct process. However, when I switched to Ecotex and used the same shirt and exact process, there were no cracking issues. I am very happy with the outcome.

While I usually prefer using Jaquard water-based ink, I decided to give this ink a try. However, I found it to be lighter and a little too creamy for my liking. As it dries faster than other inks, it tends to flake into tiny pieces. Although it still does its job, I still prefer Jaquard ink for its heavier consistency and longer runs. With this ink, you'll need to work at a faster pace.

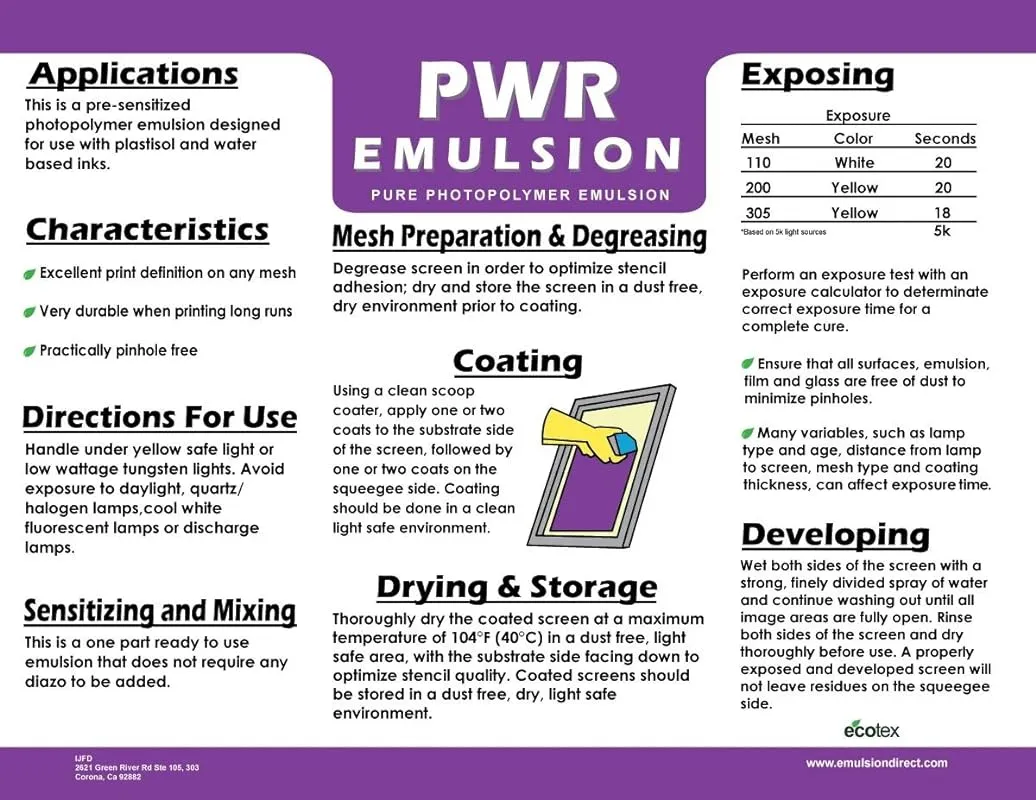

2. Silk Screen Emulsion – Eco-Friendly Printing Solution

I recently decided to try Ecotex emulsion after having some difficulties with Jacquard Diazo Emulsion. As a beginner in screen printing, I was frustrated with the lack of success I had with my screens using Jacquard. The color coding system for Ecotex initially confused me, making it difficult to choose the right emulsion. However, I decided to give it a try based on the positive reviews mentioning its suitability for beginners.

I opted for the purple PWR emulsion for my 110 screens, intending to use water-based inks. I was pleasantly surprised by the results. The consistency of the Ecotex emulsion is noticeably different from Jacquard – thicker and more jelly-like. However, it coats the screens much more easily and effectively. On my very first attempt, I successfully coated three screens perfectly.

One significant advantage I noticed was the shorter exposure times compared to Jacquard. Following the recommendation of another reviewer, I exposed the screens for 3 minutes and 10 seconds using a 500W halogen light positioned 18 inches above the screen. This exposure time worked perfectly for me, resulting in flawless screens. I wish I had followed this advice from the beginning, as it would have saved me a lot of trial and error.

I would like to express my gratitude to Ecotex for producing such a fantastic product. However, I do believe that they could improve the clarity of their product explanations to avoid confusion for customers like me. It would have saved me two months of headaches if the different emulsion options were more clearly differentiated.

For those interested, here are the specifics of my process: I used a 500-watt halogen work light with the safety glass removed, positioned 18 inches away from the screen. The burn time that worked best for me was 3 minutes and 10 seconds. I have only used this emulsion on 110 and 160 mesh screens, but it has worked well for both. I have only used water-based inks so far, but I am confident that plastisol will also work fine with this emulsion. I have yet to try reclaiming a screen, but I will update this review once I do.

3. Silkprint Deluxe: Vibrant Ink Set For T-Shirts, 4oz

I recently purchased the Speedball fabric ink kit and I must say, it exceeded my expectations. Firstly, the price of this product is incredibly reasonable, making it a great value for money. With the ample amount of paint provided in the kit, I was able to create numerous shirts, allowing me to fully explore my creativity.

However, I did encounter a minor issue with the packaging. Some of the containers had broken seals, resulting in a bit of a mess with the paint spreading onto other containers. Although this was not a major setback, it did require some cleaning up.

One of the standout features of this product is its ease of use. As a beginner in screen printing, I found the Speedball fabric ink kit to be incredibly user-friendly. I was able to create various designs on shirts effortlessly. In fact, I even experimented with mixing the colors to achieve my desired shades. This convenience definitely sets it apart from other methods such as vinyl shirts, making it a preferred choice once you become familiar with the silk screening process.

Another positive aspect of this kit is that it comes with clear instructions, allowing beginners to quickly grasp the screen printing technique. In my case, I watched just one instructional video and was able to produce a shirt that turned out surprisingly well.

To execute the screen printing process, I used a screen printing canvas with mesh material and applied vinyl on top. Using a large tool, I smoothly spread the ink onto the fabric. The ink adhered exceptionally well, although I did realize that I should have cleaned the screen a bit before applying the second layer. Additionally, I may have applied a tad too much ink. Nevertheless, both my kids loved the shirts, and after blow drying them and using a heat press to ensure they were fully dried, I was satisfied with the final results.

I must mention that the ink provided in this kit is of high quality. It produces vibrant colors that even show up on dark shirts. After heat treating the shirts, the ink forms a nice, even layer that is both durable and visually appealing. Furthermore, a little goes a long way, making this kit a cost-effective choice for beginners.

Although I did experience some minor issues with the packaging, where the red jar leaked a small amount of color onto other jars during shipping, I still highly recommend the Speedball fabric ink kit. It is a great option for those venturing into screen printing for the first time, as well as for more experienced individuals. I would definitely consider purchasing this kit again and would certainly recommend it to others.

4. Speedball Fabric Screen Printing Ink, 8-Ounce, Fluorescent Lime Green

After reading through various reviews, I wanted to provide my own objective review of this product.

Firstly, it's important to note that when printing on dark shirts, it is necessary to apply a layer of white ink first in order to achieve the desired brightness of colors. This is not a flaw in the product itself, but rather a necessary step in the printing process. So, if you are concerned about the colors not showing up well on dark shirts, simply make sure to apply a layer of white ink before adding the desired colors.

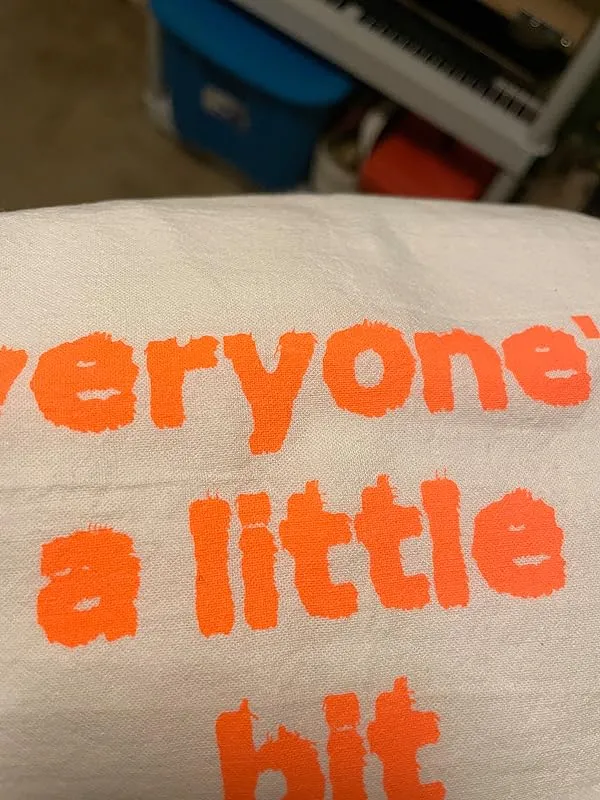

Moving on to the performance of the ink itself, I am pleased to say that it provides nice and bright colors with good coverage. In fact, I even decided to apply two coats just to be safe, and I was very satisfied with the end result. The colors showed up well and were vibrant, exceeding my expectations.

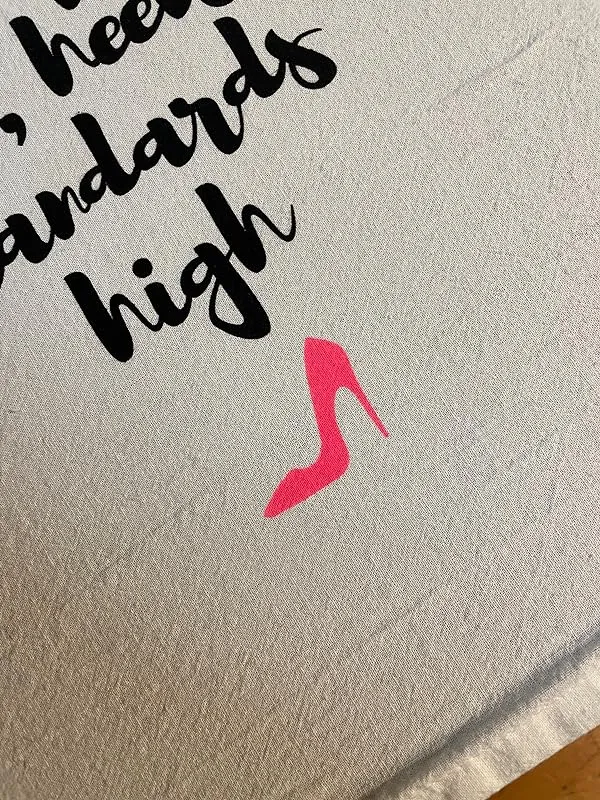

While this product works best on white shirts, it can also be used on other light colors. I have personally used the fluorescent colors on towels, and I must say, the color payoff is amazing. However, it's important to note that these inks are more watery compared to the regular line of Speedball inks. Regardless, the end result is still impressive.

As for concerns raised by other customers, I can confidently say that my experience differed. Despite being fairly new to screen printing, I decided to give this product a try. Some reviews mentioned that the colors were not as bright or fluorescent as expected, but I was pleasantly surprised by the outcome. The photos attached to my review showcase the vividness of the color, especially when printed on white paper. In order to achieve the same effect on dark colored items, it is advisable to first print a layer of white ink and then apply the desired fluorescent color. Following this method, the colors will show up beautifully.

5. Jacquard Professional Screen Print Ink, Water-Soluable, 16oz Jar, Super Opaque White (119)

I recently purchased the Jacquard water-based ink for my screen printing project, and I must say, I was very impressed with the results. Having struggled with white plastisol ink in the past, I was hoping for a better experience with this ink, especially when printing onto black hoodies. And I was not disappointed.

The opacity of this ink is truly impressive when applied using the hit-flash-hit method. The ink is thick enough to provide full coverage on dark colors, and it holds up well even after a wash and dry test. Additionally, the ink is easy to clean up with water, making the printing process much more convenient.

While I cannot compare this ink to other brands of water-based ink, I can confidently say that it outperforms Speedball. The white ink, in particular, is often considered challenging to work with due to its need for thickness to achieve opacity on dark colors. However, by adding a water-based ink softener (which can be purchased separately), I was able to achieve a softer consistency that could easily be pushed through a 230 mesh count screen. After heat curing and washing, the ink retains its softness and does not fade or wash out.

As an amateur screen printer, I have found this ink to be a great option for my projects. While I may explore more "professional" inks in the future, I am thoroughly satisfied with the performance of the Jacquard water-based ink. It is significantly easier to clean than plastisol ink, and the results are impressive.

6. Jacquard Professional Screen Print Ink, Water-Soluable, 4oz Jar, Turquoise (113)

The consistency of this ink is remarkable, allowing for a smooth and effortless application onto any garment. Its ability to glide seamlessly ensures a professional finish with every use.

However, it is important to note that this ink is on the thicker side and may require dilution with water prior to use. Failure to do so can result in potential damage to your screen, as I personally experienced. It would have been helpful if this requirement had been clearly mentioned in the product description or instructions.

Despite this setback, the color payoff of this ink is truly stunning. Once properly diluted, the beautiful hue shines through, adding a vibrant touch to any design or artwork. It effortlessly catches the eye and adds a pop of color to any garment.

7. Jacquard Professional Screen Print Ink, Water-Soluable, 4oz Jar, Super Opaque White (119)

I am extremely satisfied with this white screenprinting ink. While it may be thick, as most white inks are, it performs exceptionally well. Unlike other brands, this ink delivers a super white color on dark fabrics. It also holds up without cracking after multiple washes, ensuring longevity. If you are in search of a waterbased white ink, I highly recommend this one.

I absolutely love this white ink! Even with just one coat, it provides excellent coverage, even on a black background. Its ease of use is another standout feature. I recently used it to paint my logo on plastic jars, and the results were beautiful. The best part is that if I made any mistakes, I could easily wash it off because it is water based. Once dried for 24 hours, it becomes solid and permanent. Cleanup is a breeze as well. I'm grateful to have discovered this paint for my screen print projects.

This white ink serves as a great base with good coverage. Additionally, it has a lower setting temperature, which speeds up flash drying. I have even applied other brand inks over this one, which cured at higher temperatures, and have never encountered any issues.

For a waterborne ink, this product performs exceptionally well. My prints have endured months of washing with only slight fading. While I personally prefer using a very light print of plastisol for long-lasting prints, this ink is more than adequate and offers easier cleanup.

FAQs

Are there any limitations or challenges associated with using water-based screen printing ink that printers should be aware of?

Yes, there are certain limitations and challenges associated with using water-based screen printing ink that printers should be aware of.

1. Drying Time: Water-based inks generally have a longer drying time compared to solvent-based inks. This can slow down the production process, especially for large print runs.

2. Fabric Compatibility: Water-based inks work best on porous materials like cotton or other natural fibers. They may not adhere well to synthetic fabrics or non-porous surfaces, resulting in poor print quality.

3. Color Vibrancy: Water-based inks may not achieve the same level of color vibrancy as solvent-based inks. The colors can appear slightly muted or less vibrant on certain fabrics or substrates.

4. Washability: While water-based inks are generally more eco-friendly and easier to clean up, they may not have the same wash durability as solvent-based inks. Prints made with water-based inks may fade or wash out over time, especially if not properly cured or if subjected to harsh washing conditions.

To overcome these challenges, printers can experiment with different types of water-based inks, pretreatments, and curing techniques. It's essential to conduct thorough testing and quality control to ensure optimal results.

Additionally, printers can consider using additives or hybrid inks that combine water-based and solvent-based properties to improve performance on challenging substrates.

Are there any specific considerations or precautions to take when using water-based inks in a screen printing setup?

Yes, there are several considerations and precautions to take when using water-based inks in a screen printing setup. Firstly, it is important to ensure that the screen mesh is suitable for water-based inks, as some meshes may not be compatible and can lead to poor print quality or clogging.

It is recommended to use a mesh with a higher thread count to achieve better results.

Secondly, proper ink mixing is crucial. Water-based inks require thorough mixing to achieve a consistent viscosity and color. It is advisable to use a mixer or stirrer to ensure proper ink dispersion.

Another consideration is the drying process. Water-based inks take longer to dry compared to solvent-based inks. Therefore, it is necessary to provide adequate drying time between prints or use a forced air dryer to speed up the drying process.

Additionally, it is important to clean the screens and equipment thoroughly after each use. Water-based inks can dry quickly on the screens, leading to clogging and affecting future prints. Using a screen wash specifically designed for water-based inks will help in effective cleaning.

Lastly, it is recommended to conduct some testing before starting a full production run. This will help in understanding the ink behavior, color accuracy, and drying time on different substrates.

By following these considerations and precautions, one can achieve successful results when using water-based inks in a screen printing setup.

Are water-based inks eco-friendly and non-toxic?

Yes, water-based inks are generally considered to be more eco-friendly and non-toxic compared to other types of inks. These inks are predominantly made from water as the main solvent, along with pigments or dyes and small amounts of other additives.

One of the major advantages of water-based inks is that they have a lower impact on the environment. They do not contain harsh chemicals or volatile organic compounds (VOCs) that are often present in solvent-based inks. This means that they have lower emissions and contribute less to air pollution.

Water-based inks are also easier to clean and do not require the use of harmful solvents for cleanup.

Moreover, water-based inks are generally considered to be non-toxic. They have low levels of harmful substances, making them safer for both the environment and human health. However, it is important to note that some specific water-based inks may still contain certain additives or pigments that could be potentially toxic.

Therefore, it is essential to check the product labels or consult the manufacturer for detailed information about the specific ink being used.

Overall, water-based inks are a more sustainable and safer option compared to other types of inks, but it is always recommended to exercise caution and choose high-quality, certified products to ensure their eco-friendly and non-toxic properties.

Can water-based inks be mixed or blended to create custom colors?

Yes, water-based inks can be mixed or blended to create custom colors. One of the advantages of water-based inks is their ability to be easily mixed together to achieve different shades and hues. To mix water-based inks, start by selecting the desired colors and placing small amounts on a palette or mixing surface.

Then, use a brush or palette knife to blend the colors together until the desired shade is achieved. It is important to note that when mixing water-based inks, it is best to use colors within the same brand or line to ensure compatibility.

Additionally, experimenting with different ratios and combinations of colors can help achieve unique and customized shades. Overall, the process of mixing water-based inks allows for flexibility and creativity in creating custom colors for various art and design projects.

Can water-based inks be used on various types of fabric or are they limited to specific materials?

Water-based inks can be used on a wide range of fabric types, making them versatile for various applications. These inks are suitable for natural fibers such as cotton, linen, silk, and rayon, as well as synthetic fibers like polyester and nylon.

They can also be used on blended fabrics that contain a combination of natural and synthetic fibers.

However, it is important to note that water-based inks may not be as effective on certain fabrics with water-repellent finishes or coatings. In such cases, it is recommended to test the ink on a small, inconspicuous area of the fabric before proceeding with a larger application.

Additionally, some fabrics may require pre-treatment or special additives to optimize the adhesion and durability of the water-based ink. This is particularly relevant for fabrics with low absorbency, such as polyester.

Consulting with a professional fabric printer or ink manufacturer can provide valuable guidance on the specific requirements for different fabric types.

In summary, while water-based inks are generally compatible with various fabric materials, it is advisable to test their suitability on specific fabrics and seek expert advice when needed.

How does the drying time of water-based inks compare to other types of inks in screen printing?

The drying time of water-based inks in screen printing generally tends to be longer compared to other types of inks. This is because water-based inks rely on the evaporation of water to dry and set on the printing surface.

The drying process can vary depending on factors such as humidity, temperature, and the thickness of the ink layer.

In contrast, other types of inks, such as solvent-based or plastisol inks, often contain chemicals or additives that promote faster drying. Solvent-based inks typically dry through the evaporation of solvents, while plastisol inks undergo a curing process when exposed to heat.

To expedite the drying time of water-based inks, screen printers can take certain measures. Increasing air circulation, using drying equipment, or placing prints in a controlled drying environment can help accelerate the drying process.

Additionally, using thinner ink layers and ensuring proper screen tension can also aid in reducing drying time.

Overall, while water-based inks may have a longer drying time compared to other types of inks in screen printing, they offer advantages such as eco-friendliness, softer feel, and compatibility with a wider range of substrates.

How does water-based screen printing ink affect the durability and washability of printed designs?

Water-based screen printing ink can have a significant impact on the durability and washability of printed designs. This type of ink is designed to be more environmentally friendly and easier to clean up compared to traditional solvent-based inks.

In terms of durability, water-based inks generally provide good adhesion to fabrics, resulting in designs that can withstand regular wear and tear. However, they may not be as durable as solvent-based inks, especially when it comes to heavy-duty applications or garments that undergo frequent washing or abrasion.

To enhance durability, it is important to properly cure the printed designs using heat or other recommended methods as per the ink manufacturer's instructions.

When it comes to washability, water-based inks are generally quite satisfactory. They tend to have good colorfastness and resistance to fading when washed with mild detergents and cold water. However, for best results, it is recommended to follow the specific washing instructions provided by the ink manufacturer, as different brands may have slightly different performance characteristics.

Overall, while water-based screen printing ink offers environmental advantages and ease of use, it is important to consider factors such as proper curing and following recommended washing instructions to ensure the durability and washability of printed designs.

What are the advantages of using water-based screen printing ink?

Water-based screen printing ink offers several advantages over other types of inks. Here are some key benefits:

1. Environmentally friendly: Water-based inks are non-toxic and have a lower impact on the environment compared to solvent-based inks. They do not contain harmful chemicals or volatile organic compounds (VOCs), making them a safer choice for both the printer and the environment.

2. Soft and breathable prints: Water-based inks produce softer and more breathable prints compared to other types of inks. This is particularly beneficial for printing on fabrics, as the ink becomes a part of the fabric and does not create a heavy or stiff texture.

3. Wide color range: Water-based inks offer a wide range of vibrant and opaque colors. They can be easily mixed to create custom colors, giving the printer more flexibility and creativity in the design process.

4. Easy cleanup: Water-based inks are easy to clean up with water, eliminating the need for harsh chemicals or solvents. This not only saves time and effort but also reduces the exposure to toxic substances.

5. Versatility: Water-based inks can be used on a variety of materials, including fabrics, paper, and wood. They can also be used for both light and dark-colored substrates, making them a versatile choice for different printing projects.

Overall, the advantages of using water-based screen printing ink include environmental friendliness, soft prints, a wide color range, easy cleanup, and versatility in printing applications.

What are the different techniques and methods for working with water-based screen printing ink?

There are several techniques and methods for working with water-based screen printing ink. Here are a few commonly used ones:

1. Preparing the screen: Start by properly degreasing and coating the screen with emulsion. Make sure the screen is completely dry before proceeding.

2. Mixing the ink: Water-based inks are usually supplied in a concentrated form. To achieve the desired color, you can mix the ink with water or a color pigment. Stir the mixture thoroughly to ensure a consistent color and texture.

3. Screen setup: Set up the screen on the printing press and align it with the substrate. Use masking tape or adhesive to secure the screen in place.

4. Flood the screen: Flood the screen with ink using a squeegee. Make sure the ink covers the entire image area evenly.

5. Printing: Position the substrate underneath the screen and apply downward pressure with the squeegee, pulling the ink across the screen. Repeat the process for each print.

6. Drying: Water-based inks dry through evaporation. Allow the prints to air dry or use a heat gun or conveyor dryer to speed up the process.

7. Clean-up: Clean the screen, squeegee, and other tools with water immediately after printing to prevent the ink from drying and clogging the screen.

It's important to note that specific techniques and methods may vary depending on the equipment and materials you are using. Experimentation and practice will help you refine your skills with water-based screen printing ink.

What is water-based screen printing ink and how does it differ from other types of inks?

Water-based screen printing ink is a type of ink that is specifically designed for screen printing applications. Unlike other types of inks, water-based screen printing ink is made primarily from water, along with pigments, binders, and additives.

One of the key differences between water-based screen printing ink and other types of inks is its composition. Water-based inks have a lower viscosity, meaning they are thinner and more fluid than other inks.

This allows for better penetration into the fabric during printing, resulting in a softer and more comfortable finish.

Another important difference is the environmental impact. Water-based inks are generally considered to be more eco-friendly compared to solvent-based or plastisol inks. They have lower volatile organic compound (VOC) emissions and are free from harmful chemicals such as phthalates and PVC.

Water-based inks also offer excellent color vibrancy and can be easily mixed to create a wide range of colors. They are suitable for printing on a variety of substrates, including cotton, polyester, and blends.

However, they may require a longer drying time compared to other inks, and additional steps like heat setting or curing may be necessary to ensure durability and washability.

Overall, water-based screen printing ink is a versatile and environmentally friendly option that provides high-quality prints with a soft feel.