I Tested And Reviewed 10 Best Glue For Vinyl Plank Flooring (2023)

Installing vinyl plank flooring can transform the look and feel of any room in your home. With its realistic wood and stone designs, vinyl plank flooring offers beauty and durability at an affordable price point. But with so many glue options on the market, how do you know which one is right for your vinyl plank flooring project?

When researching the best glue for vinyl plank flooring, you’ll want to consider factors like flooring location, moisture levels, versatility, and ease of use. Is your new floor going in a bathroom, kitchen or heavily trafficked area? Are you installing over concrete or wood? The answers to these questions will help guide you to the ideal adhesive. You’ll also want to think about whether you need just a standard glue or a moisture barrier too.

Got questions about tackling a vinyl plank flooring installation? Unsure which variables matter most when picking the perfect glue? Want to better understand how moisture factors into the equation? By doing your homework before starting an installation, you can set your project up for long-lasting success. The right adhesive will keep your new vinyl flooring in place for years to come.

10 Best Glue For Vinyl Plank Flooring

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for both professional and DIY installations of luxury vinyl plank flooring.

|

|

||

|

2

|

The product is ideal for adding a realistic wood plank look to any room with its self-adhesive design.

|

|

||

|

3

|

The product is ideal for installing vinyl flooring and can be used with various types of materials.

|

|

||

|

4

|

The product is ideal for DIY installation of luxury vinyl flooring tiles with a stone look.

|

|

||

|

5

|

The product is ideal for bonding and adhering various materials, such as wood, tile, linoleum, and carpet, to floors.

|

|

||

|

6

|

The product is ideal for DIY home flooring installations, providing a stylish and durable wood-look finish.

|

|

||

|

7

|

The product is ideal for bonding floor tiles together effectively and securely.

|

|

||

|

8

|

The product is ideal for adhering vinyl-composition and vinyl-asphalt structurally sound plywood for underlayment quality tile installation.

|

|

||

|

9

|

The product is ideal for bonding floating floor materials together securely and effectively.

|

|

||

|

10

|

The product is ideal for bonding and repairing various materials.

|

|

1. Msi Hampstead Vinyl Plank Flooring: Pro & Diy Installation

The installation of this product is seamless and exudes a luxurious appearance. The textured surface successfully replicates the look of real wood, adding to its appeal. It is important to ensure that the surface is adequately prepared beforehand, as any irregularities may be visible through the planks.

I recently utilized this LVT flooring for a house flip project in my laundry room basement. I was seeking a cost-effective solution that didn't compromise on quality, and this product fit the bill perfectly. Compared to the higher-end options that typically cost around $4-$5 per foot, this flooring came at a more affordable price of approximately $2. Despite being thinner than its pricier counterparts, it still delivers an impressive aesthetic and appears to be durable. I am pleased with the outcome and will consider using it again for future projects that align with its specifications. Not only was the purchasing process hassle-free, but the product also arrived promptly with the added convenience of free shipping and returns if necessary.

Upon installation, this product transformed my house and added a touch of elegance. To my surprise, it also came with a lifetime warranty, which further contributes to its appeal. I highly recommend this flooring to anyone looking to elevate the quality of their floors without compromising on visual appeal.

In terms of cutting the material, I found that a small table saw did the job without causing any chipping, ensuring a clean finish. However, please note that my experience is limited to using these planks for an accent wall rather than as a floor. If you are specifically looking for a product to enhance your accent wall, these planks are an ideal choice. They boast a low-profile design and feature a delightful texture that elevates the overall aesthetic.

2. Easy Diy Wood Plank Vinyl Floor Tiles

The peel and stick plank flooring is a budget-friendly option that provides a realistic wood look. While it may not be suitable for high-end wood floor enthusiasts, it serves its purpose well. Installation is a breeze, with the tiles easily sticking to the floor surface. The color is a rich brown, resembling old rustic boards, making it a great fit for rustic farmhouse-style homes.

In terms of durability, it may require additional maintenance over time, but the initial installation holds up well without the need for extra glue. Some reviewers suggest using color seal touchup solutions to fill in gaps, which saves time and effort. For the price, this flooring is a great steal. Even without considering the affordability, it still proves to be a reliable choice.

One reviewer, a realtor with experience in the industry, attests to the quality of this product. They provide helpful tips, such as sliding the tiles under the baseboard instead of removing it and starting the installation a plank away from the wall. These insights enhance the overall installation process.

Another user shares their positive experience using the peel and stick planks to cover their kitchen cabinets. They were looking for a cost-effective solution and found this product to be perfect. The planks have a realistic texture and a medium color tone, making them visually appealing. However, the glue provided with the product is not sufficient, so they recommend using an all-purpose liquid nail glue for better adhesion. Despite this minor inconvenience, the reviewer emphasizes that the planks have remained in place for several months.

It is important to note that this product may not be suitable for high traffic floor areas due to its thin nature. However, for covering kitchen cabinets or other non-flooring applications, it proves to be an excellent option.

3. Roberts 7350-1 1 Gallon Universal Vinyl Flooring Adhesive, Off White

I recently used this adhesive for gluing vinyl plank flooring to a concrete subfloor, and I must say it is the best adhesive I have come across. It was incredibly easy to apply using a 1/16 x 1/16 trowel, and the clean-up was a breeze. Once the adhesive sets, it becomes extremely tacky and securely holds each plank in place. I have had issues with floating floors in the past, so I decided to try the glue-down method, and I am thrilled with the results. I used Lowe's SmartCore planks without backing, and they worked perfectly with this adhesive.

A helpful tip for using this adhesive on concrete is to first clean the surface thoroughly using a floor grinder to remove any paint overspray, drywall mud, or old carpet adhesive. Applying the adhesive on bare concrete allows for maximum bond and results in a quiet floor with a professional look.

I also used this adhesive to lay peel and stick laminate on concrete in my basement, and I highly recommend allowing it to set for several hours before laying anything on top. Initially, the adhesive is quite wet and does not hold the tiles well. However, once it sets and becomes firm and tacky, it provides a much better grip and makes the project a lot easier. Additionally, this adhesive dries clear, which is convenient as it allows you to see chalk lines and ensures a seamless finish.

As a first-time user of glue-down LVP, I found this adhesive to be quite impressive. I appreciated the fact that it dries clear, which made it easier to work with and follow chalk lines. I used it on a basement floor that wasn't completely flat, so I had to apply extra adhesive in low spots. While it took a bit longer for these areas to dry clear (around 6 hours), I was pleased with the adhesive's long working time. It remains super sticky even after sitting outside for days.

However, I did encounter a minor issue with one of the pails. It seems that it was not properly sealed, as some glue oozed out around the lid. I suggest the supplier considers taping the lid shut to prevent this from happening during delivery.

After extensive research, I chose this adhesive for installing a vinyl plank floor in our basement, and I am glad I did. When installing glue-down flooring on a slab, it is crucial to check for moisture emission in the cement. This adhesive has one of the highest moisture control rates on the market, making it a reliable choice. I have had the floor installed for over two years now, and I have experienced zero issues, despite the high moisture rate in my basement.

One thing to note is that you need to work quickly with this adhesive, as it can become goopy on the trowel and potentially create a mess. However, once you find your rhythm, the installation process goes smoothly and efficiently. Overall, I highly recommend this adhesive for any glue-down flooring projects.

4. Luxury Vinyl Flooring: Gluecore+ Stone-Look Planks (Box Of 18)

I am extremely satisfied with the flooring in my home. Not only do I love the way it looks, but I also take great pride in the fact that I installed it myself. The flooring has a stunning resemblance to real marble, which adds a touch of elegance to my space. The quality of the product is exceptional, especially considering the affordable price. I was pleasantly surprised by how easy it was to install, even for someone like me who is not a professional. Overall, I highly recommend this flooring for its beautiful appearance, great value for money, and user-friendly installation process.

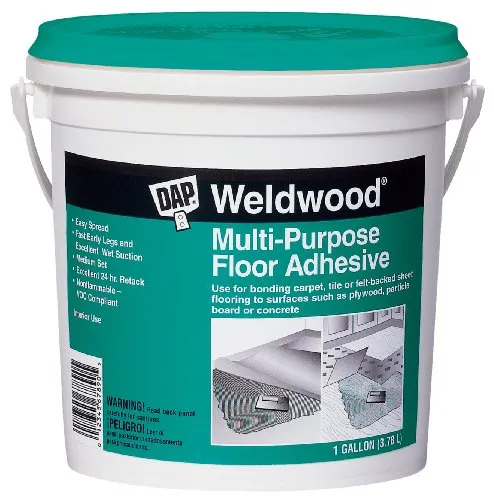

5. Dap 142, Gallon 00142 Weldwood Multi-Purpose Floor Adhesive, White

I recently installed a linoleum floor using this adhesive and I have to say, it was a breeze. As a first-timer, I was worried about the process, but it turned out to be quite simple. I used painting paper to create a template, traced it onto the linoleum, and cut the piece with a sharp box knife. Applying the adhesive with a notch trowel was easy, and I used a marble rolling pin to ensure a smooth surface. I repeated the process for the other half of the floor and the result was fantastic.

I did experience some mess with the adhesive, but I found using a paint brush and giving it texture helped with the application. I also used gloves and a cookie sheet with plastic wrap to contain the adhesive and keep my work area clean. Any adhesive that got on my skin was easily removed with soap and a rough sponge.

This adhesive exceeded my expectations. It made working with tiles and wallpaper a breeze, and it was especially helpful for my older home where I didn't want to sand anything down. It dries quickly and any remaining adhesive can be easily removed with alcohol. I've already completed projects in my bathroom and living room with just one can, and I will definitely be ordering more for future quarantine projects.

However, I do understand that some people have had negative experiences with this adhesive. It's important to follow the instructions and wait until you see sticky strings before moving forward. I personally had no issues with lifting or oozing, but I can see how it could happen if the instructions are not followed properly.

6. Lucida Surfaces Luxury Vinyl Flooring – Harbor Grey

As a first-time DIY-er, I embarked on a project to install new flooring for my parents. Initially, I purchased a low-end peel-and-stick product from Home Depot, but it quickly showed signs of wear and tear even before I began the project. Determined to find a higher quality option, I came across Lucida flooring, and I must say, it exceeded my expectations.

One of the standout features of this flooring is its excellent quality. I was particularly impressed with the ease of cutting it with scissors, which made the installation process much smoother. Opting for the glue-down method instead of peel-and-stick, I appreciated the flexibility it provided in case I needed to rearrange any pieces. Prior to laying down the flooring, I meticulously cut and fitted each piece, numbering them with tape for added organization.

Preparing the floor to ensure it was level proved to be the most challenging aspect of the project. However, with perseverance and attention to detail, I was able to overcome this hurdle. Overall, I am extremely satisfied with the end result of my DIY endeavor.

Looking ahead to future projects, such as redoing my parents' kitchen floor, I would definitely consider using Lucida flooring again. I might even give the peel-and-stick option a try. Regardless of the type chosen, I highly recommend Lucida flooring for its durability and quality. Additionally, their customer service proved to be exceptional. When I had to return a previous product due to a change in color preference, Lucida promptly refunded me without any hassle.

7. Dap 00136 Weldwood Floor Tile Adhesive, 1-Quart,clear

I recently used this tile adhesive for an art project where I needed to adhere ceramic tiles of different thicknesses to a floor. Despite not being the recommended application, the adhesive stayed flexible and held the tiles in place well enough for my needs. One aspect I particularly liked about this adhesive is that it does not produce any fumes. Additionally, its flexibility and ability to adhere to the tiles were commendable. However, I must emphasize that this review is not a recommendation for artists, but rather a reflection of my personal experience.

Although I have not personally used this adhesive yet, a friend who owns a flooring store advised against purchasing the gallon size for a small linoleum project in a bathroom. Nonetheless, based on my friend's assurance that the adhesive would provide the same quality as his company's work, I have confidence that it will do the job effectively. It's worth mentioning that my project is located in a different state, specifically in my father's house.

I purchased this adhesive some time ago, and I am pleased with its performance so far. It adheres well, and none of the tiles have popped up. I highly recommend it for similar tiling projects.

For my bathroom re-tiling project, this floor tile adhesive was exactly what I needed. It covered the required area perfectly, and I even had some leftover for future tiling jobs. I will definitely purchase it again.

I used this adhesive when replacing vinyl tiles, and it seemed to do the trick. However, I cannot yet determine its durability as it is still early in the process.

8. Underlayment Quality Tile Adhesive: Roberts Vinylstrong Quart

I am extremely impressed with this product! After experiencing issues with peel and stick tiles popping up in the past, I decided to give this adhesive a try, and I am so glad I did. I used a paint brush to apply it to the back of the tiles and allowed it to dry for 24 hours. To my delight, the tiles did not budge even when I pushed heavy furniture across them. This adhesive is incredibly effective at keeping everything in place.

Furthermore, I found this product to be versatile in its applications. Not only did it help me re-stick old flooring tiles, but it also provided the extra sticking power I needed for new peel and stick vinyl planks. Additionally, I used it to secure peel and stick faux brick on the walls during our home renovation, and it worked like a charm. It has truly made our DIY updates more permanent, which is exactly what we were looking for.

However, it is worth noting that this adhesive is incredibly sticky. During the application process, I accidentally got some on my hands, and it was a challenge to remove. Despite using rubbing alcohol and acetone, the adhesive remained stubbornly stuck. I even tried using black vinyl gloves, but they too became sticky and hindered my finger movement. In the end, I decided to tolerate the sticky fingers for a few days because the effectiveness of this adhesive outweighed the inconvenience.

Lastly, I want to mention that this adhesive was a lifesaver for me when I was replacing the vinyl flooring in my bathroom. The floor had uneven dips due to past water damage, and while the adhesive didn't level off the major imperfections perfectly, it did the job of keeping the tiles in place. I did have to be cautious because this adhesive can be messy and sticky, so I recommend wearing gloves and using it sparingly as a little goes a long way.

9. Cal-Flor Gl82114cf Eurobond D3 Floating Floor Glue

I recently purchased and used this flooring adhesive for installing 5" flooring in a 1300 sqft area. Initially, I was skeptical about the quantity, so I ordered additional bottles. However, to my surprise, one bottle was enough to cover around 350-400 sqft with some leftover. The application process was smooth and easy.

According to the instructions, the adhesive requires 24 hours for foot traffic and has a set time of 10-15 minutes. To expedite the drying process, we used an i-heater and turned on the ceiling fan. Fortunately, we didn't encounter any issues during this phase.

One impressive aspect of this adhesive is its durability. Even when we had to pause halfway through a room, the edge where we stopped did not pose any tripping hazard. I accidentally stepped on the edge after 2 hours of installation, expecting the flooring to pop out, but it remained intact. The joint didn't even flex, although it may do so under more pressure.

After the recommended 24-hour drying period, we tested the floors by walking, jumping, and sliding heavy furniture across them. We actively listened for any popping sounds or checked for joints that might separate, but everything remained solid. However, only time will truly reveal the long-term performance, so I will update my review if necessary.

Here are a few tips for using this adhesive effectively. Firstly, use the smallest opening on the cap and cut at an angle for precise application. You don't need to use excessive amounts, as the glue runs easily. Additionally, keep some towels or rags nearby to clean up any occasional drips or poor aim.

I must mention that wiping the spout down with a damp towel before putting on the black cover/cap is essential.

*UPDATE*

It has been 18 months since we installed our floors with this adhesive, and I continue to be impressed with its performance. Our kitchen flooring, which was a major concern due to potential water damage, has proven to be resilient. Even a dishwasher leak did not penetrate the glued areas.

The only issue we encountered was a slightly uneven joint in a heavily trafficked area. This caused a small clicking sound over the summer, indicating a breakdown in the glue bond. To rectify this, I secured the area with a few screws under the baseboards, and there have been no further problems.

I am updating this review because we are now installing an additional 1200 sqft of the same flooring, this time over a concrete floor. Despite concerns about humidity, I have confidence in this adhesive's ability to deliver excellent results once again.

10. Rhino Glue Gel, Heavy Duty 40 Gram Clear

I had a similar experience to many others when the window on my Mustang 2010 convertible separated from the vinyl top. After contacting several repair shops, all of them insisted that it was impossible to fix and that I needed to replace the entire top for $1500. However, I was determined to find an alternative solution and came across Rhino Glue while researching online.

Based on the recommendations of numerous people in forums, I decided to give Rhino Glue a try. Following their instructions, I opened the top slightly, about 5 inches, to relieve pressure on the seams. I then thoroughly cleaned the window and all edges using a razor blade and acetone. I applied a thin layer of glue using a plastic card, being careful to cover the glass with masking tape to avoid excess glue. Working in 5-inch increments, I applied the glue, held it down for a minute, and moved on to the next section. The entire process took a little over an hour, and the adhesive proved to be incredibly strong.

To ensure a solid bond, I left the car in the garage with the top open for two days. The Rhino Glue hardened like a rock, and I have no doubt that it will last for a considerable amount of time. I even took my car through a car wash with heavy brushes, and the window remained securely attached. It's worth mentioning that there were a few mishaps on my end due to lack of caution. I accidentally got glue on the vinyl, which caused discoloration when I attempted to remove it with acetone. I also inadvertently placed the plastic card on my trunk, resulting in glue getting on my paint. Lastly, the masking tape became stuck to the glue, making it difficult to remove. However, I was able to rectify these issues by using a razor blade to remove excess glue and tape.

Initially, I was apprehensive about attempting this repair myself, but it turned out to be a straightforward process. The Rhino Glue kit comes with two bottles, and I barely made a dent in the smaller one. This should last me a lifetime, and I'm excited to find other uses for it.

In terms of longevity, I am delighted to report that it has been over five months since I repaired the window, and it is still securely attached. I have driven through countless car washes, traveled over 6000 miles across the United States, and even experienced extreme temperature fluctuations from freezing temperatures to scorching desert heat in California. Despite these challenging conditions, the window remains in the same condition as the day I glued it. I continue to be amazed every time I see my car and touch the seams.

As of December 2017, the window remains firmly attached, further demonstrating the durability and effectiveness of Rhino Glue. I highly recommend this product for anyone facing a similar issue with their convertible top. With proper care and attention to detail, Rhino Glue can provide a reliable and long-lasting solution, saving you both time and money.

FAQs

Are there any disadvantages of using glue for vinyl plank flooring installation?

Yes, there are some potential disadvantages to using glue for vinyl plank flooring installation.

Firstly, using glue can be messier and more time-consuming compared to other installation methods such as click-lock or loose lay. Glue application requires careful and precise spreading, which can be challenging for beginners or inexperienced installers.

Secondly, using glue can make future repairs or replacements more difficult. Once the vinyl planks are glued down, it can be challenging to remove and replace individual planks if they get damaged or need to be changed. This can result in higher costs and more extensive labor if repairs are needed.

Thirdly, some adhesives used for vinyl plank flooring may emit volatile organic compounds (VOCs), which can be harmful to indoor air quality. It's important to choose low or zero VOC adhesives to minimize potential health risks.

Lastly, using glue may limit the flexibility of the installation. Glue-down vinyl flooring is typically more permanent compared to other installation methods, making it less suitable for temporary or frequently changing spaces.

Considering these potential disadvantages, it may be worth exploring alternative installation methods such as click-lock or loose lay if they are suitable for your specific needs and preferences.

Are there any specific instructions for applying glue to vinyl plank flooring?

Yes, there are specific instructions for applying glue to vinyl plank flooring. Here's a step-by-step guide:

1. Prepare the surface: Ensure that the subfloor is clean, dry, and free of any debris or imperfections. Vacuum or sweep the area thoroughly before proceeding.

2. Choose the right adhesive: Select a high-quality adhesive that is recommended for vinyl plank flooring. Consult the manufacturer's guidelines to find the appropriate adhesive for your specific flooring type.

3. Follow the manufacturer's instructions: Read and follow the instructions provided by the adhesive manufacturer carefully. They will provide specific details on application techniques, coverage rates, and drying times.

4. Apply the adhesive: Using a trowel or recommended applicator, spread the adhesive evenly on the subfloor. Work in small sections at a time to ensure proper coverage.

5. Install the vinyl planks: Begin laying the vinyl planks immediately after applying the adhesive. Press each plank firmly into place, ensuring a tight bond with the adhesive.

6. Wipe off excess adhesive: Any excess adhesive that squeezes out between the planks should be wiped off immediately with a damp cloth or sponge. This will prevent it from drying and leaving visible residue on the flooring surface.

7. Allow adequate drying time: Follow the adhesive manufacturer's instructions regarding the recommended drying time before allowing foot traffic or placing heavy objects on the newly installed vinyl plank flooring.

It is important to note that not all vinyl plank flooring requires glue for installation. Some vinyl plank flooring options are designed to be installed as floating floors without the need for adhesive. Always refer to the manufacturer's instructions for the specific product you are using.

Can I install vinyl plank flooring without using glue?

Yes, you can install vinyl plank flooring without using glue. There are two common methods for installing vinyl plank flooring without glue: floating installation and click-lock installation.

Floating installation involves interlocking the vinyl planks together without using any adhesive. The planks are laid directly on the subfloor or a foam underlayment, allowing them to expand and contract with temperature changes.

This method is popular because it is relatively easy to install and allows for flexibility in case you want to change the flooring in the future.

Click-lock installation, on the other hand, involves using a locking mechanism on the edges of the planks to securely connect them together. This method also does not require glue and allows for easy installation and removal.

Both floating and click-lock installations offer a convenient and glue-free option for installing vinyl plank flooring. However, it is important to carefully follow the manufacturer's instructions and ensure that your subfloor is clean, level, and properly prepared for a successful installation.

Can I use regular wood glue for vinyl plank flooring?

No, regular wood glue is not suitable for vinyl plank flooring. Vinyl plank flooring requires a specific adhesive that is designed to bond vinyl materials. Regular wood glue may not provide the necessary strength and flexibility needed for vinyl plank flooring installation.

It is important to use an adhesive that is specifically formulated for vinyl flooring to ensure proper installation and durability. These adhesives are typically water-based and have specific properties that allow for a secure bond while also allowing the vinyl planks to expand and contract.

Using the wrong type of adhesive could lead to issues such as lifting, buckling, or gaps in the flooring. Therefore, it is recommended to use the manufacturer-recommended adhesive for your vinyl plank flooring installation to ensure optimal results.

Can I use the same glue for vinyl plank flooring on other types of flooring materials?

While it may be tempting to use the same glue for vinyl plank flooring on other types of flooring materials, it is generally not recommended. Different flooring materials have different installation requirements and adhesive compatibility.

Using the wrong type of glue can lead to poor adhesion, uneven installation, and potential damage to the flooring.

It is important to consult the manufacturer's instructions and guidelines for each specific flooring material to determine the appropriate adhesive to use. They often provide recommendations for compatible adhesives that are designed to work best with their particular flooring product.

If you are unsure about the appropriate adhesive for a specific flooring material, it is always best to reach out to the manufacturer or consult with a professional installer who has experience working with that particular type of flooring.

They can provide expert advice and ensure that you choose the right adhesive for a successful and durable installation.

How do I remove glue from vinyl plank flooring?

To remove glue from vinyl plank flooring, you can follow these steps:

1. Start by scraping off as much of the glue as possible using a plastic scraper or putty knife. Be careful not to scratch or damage the flooring.

2. After scraping, dampen a cloth or sponge with warm water and gently rub the glue residue. This can help soften the glue and make it easier to remove.

3. If warm water alone doesn't work, you can try using a mild detergent mixed with warm water. Apply the solution to the glue residue and let it sit for a few minutes. Then, scrub the area gently with a soft-bristle brush or sponge.

4. For stubborn glue or adhesive, you may need to use a commercial adhesive remover. Make sure to follow the instructions provided by the manufacturer and test the product in a small, inconspicuous area first to ensure it doesn't damage the vinyl flooring.

5. Once the glue is removed, rinse the area with clean water and dry it thoroughly to prevent any moisture damage to the flooring.

If you're unsure about using certain products or techniques on your specific vinyl plank flooring, it's always recommended to consult the manufacturer's guidelines or seek professional advice.

How long does the glue for vinyl plank flooring take to dry?

The drying time for glue used with vinyl plank flooring can vary depending on the specific product and conditions. In general, it typically takes around 24 to 48 hours for the glue to fully dry and cure.

However, it is important to note that this is just an estimate and can be influenced by factors such as temperature, humidity, and ventilation.

To ensure proper drying, it is recommended to follow the manufacturer's instructions for the specific glue being used. They may provide specific guidelines regarding drying time and conditions. It is essential to allow sufficient drying time before placing any weight or walking on the newly installed vinyl plank flooring to avoid any damage or displacement.

If you are unsure about the drying time or have any concerns, it is best to consult with the manufacturer or a professional installer for guidance specific to your situation.

Is there a specific brand of glue that works best for vinyl plank flooring?

When it comes to choosing a glue for vinyl plank flooring, it is important to select one that is specifically designed for this type of flooring. One popular and reliable option is a pressure-sensitive adhesive (PSA) that is specifically formulated for vinyl plank flooring installation.

These adhesives are typically water-based and provide a strong bond between the vinyl planks and the subfloor.

Another option is a solvent-free, acrylic-based adhesive. This type of adhesive is also designed for vinyl plank flooring and provides a strong bond while being environmentally friendly.

It is best to consult with the manufacturer of your vinyl plank flooring to determine the recommended adhesive for your specific product. They will have the expertise and knowledge to guide you in selecting the most suitable glue for your flooring.

Additionally, following the manufacturer's instructions for installation is crucial to ensure the longevity and performance of your vinyl plank flooring.

What are the advantages of using glue for vinyl plank flooring installation?

There are several advantages to using glue for vinyl plank flooring installation. Firstly, using glue ensures a more secure and stable installation. The adhesive creates a strong bond between the vinyl planks and the subfloor, preventing any movement or shifting over time.

This is particularly beneficial in high traffic areas or spaces prone to moisture, as it helps to prevent the planks from warping or buckling.

Secondly, glue provides better sound insulation. By adhering the vinyl planks directly to the subfloor, it helps to muffle sound and reduce noise transmission, creating a quieter and more comfortable environment.

Furthermore, using glue allows for a seamless appearance. With glue-down installation, there are no gaps or spaces between the planks, resulting in a smooth and uniform surface. This not only enhances the aesthetic appeal of the flooring but also makes it easier to clean and maintain.

Lastly, glue-down installation is generally more durable and long-lasting. The adhesive provides extra strength and stability, ensuring that the vinyl planks stay firmly in place even under heavy use.

Overall, using glue for vinyl plank flooring installation offers advantages such as increased stability, better sound insulation, a seamless appearance, and improved durability.

What type of glue is recommended for vinyl plank flooring installation?

When it comes to installing vinyl plank flooring, a common method is the floating floor installation, which does not require any glue. However, if you're looking to use adhesive for extra stability or in specific situations, it's important to choose the right type of glue.

For vinyl plank flooring, it is generally recommended to use a pressure-sensitive adhesive (PSA) specifically designed for vinyl flooring. PSA adhesives are easy to use, as they have a sticky backing that bonds well with vinyl materials.

They are also flexible, allowing the flooring to expand and contract with temperature changes.

It's important to follow the manufacturer's recommendations for the specific brand and type of vinyl plank flooring you have, as some manufacturers may have their own recommended adhesives. Additionally, consider factors such as the subfloor material and conditions, as they may influence the choice of adhesive.

If you're unsure about the type of glue to use for your vinyl plank flooring installation, it's always best to consult the manufacturer or a professional installer for their expert advice.