I Tested And Reviewed 10 Best Printer For Printing On Fabric (2023)

Looking to print your own fabric designs? With the right printer, you can unleash your creativity and print stunning images directly onto fabric. But with so many fabric printers on the market, how do you choose the right one? Here are some key factors to consider before making your purchase.

First, think about the type of fabric you'll be printing on most often. The fabric composition – whether it's 100% cotton, polyester blend, etc. – determines what kind of ink and printer settings you'll need for optimal image quality. Heavier fabrics like canvas require a higher ink volume than lighter cottons and silks.

Next, consider the print size and resolution you need. Standard fabric printers can print a maximum area of 8.5"x11" or 8.5"x14". For larger pattern repeats or full fabric widths, look for a wide-format printer that can accommodate fabric sheets up to 42". Print resolution ranges from 720×720 dpi to 1440×1440 dpi and higher for photographic detail.

The printing method is also a factor. Dye sublimation printers offer continuous tones and vibrant colors for polyester fabrics. Pigment ink printers work on both natural and synthetic fabric types. And latex printers apply a textured overlay ideal for fabrics like t-shirts.

By taking the time to assess your fabric, design, and application needs beforehand, you'll be able to zero in on the perfect fabric printer to bring your textile visions to life. Let your creativity run wild!

10 Best Printer For Printing On Fabric

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for creating photo-quality prints on dark and light/white fabrics using inkjet printers.

|

|

||

|

2

|

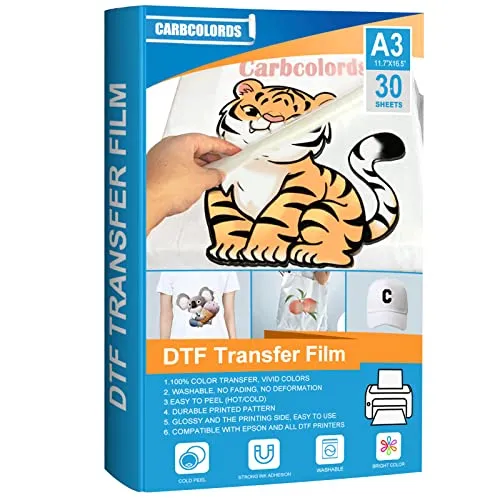

The product is ideal for direct printing on any colored/white fabric using a DTF printer and film.

|

|

||

|

3

|

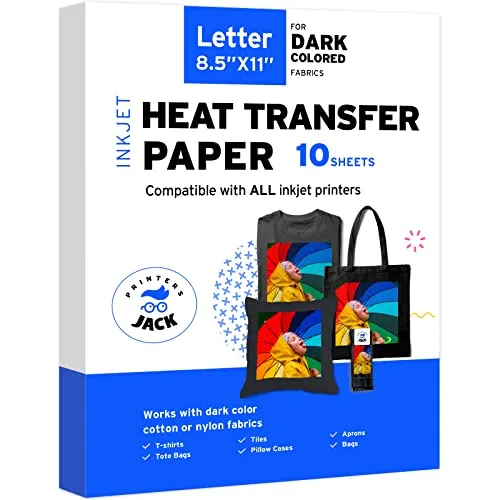

The product is ideal for printing and transferring designs onto dark colored t-shirts.

|

|

||

|

4

|

The product is ideal for direct printing on t-shirts, textile, and all types of fabrics.

|

|

||

|

5

|

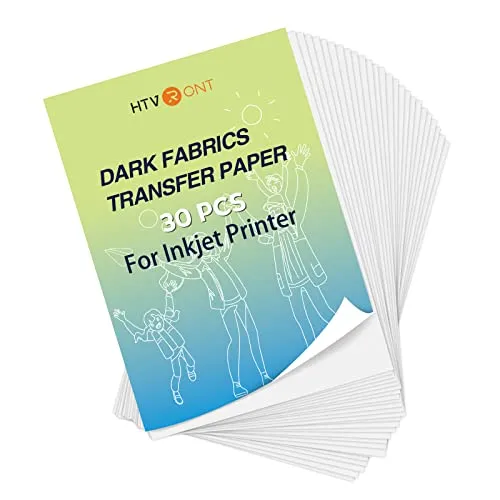

The product is ideal for making durable, long-lasting transfers on dark fabrics without cracking using an inkjet printer.

|

|

||

|

6

|

The product is ideal for creating DIY Christmas presents and crafts on dark or white/light fabrics using inkjet printers.

|

|

||

|

7

|

The product is ideal for transferring vibrant and durable designs onto dark T-shirts using an inkjet printer.

|

|

||

|

8

|

The product is ideal for creating customized designs on dark fabric T-shirts.

|

|

||

|

9

|

The product is ideal for printing designs on T-shirts and cotton textiles using DTF printers.

|

|

||

|

10

|

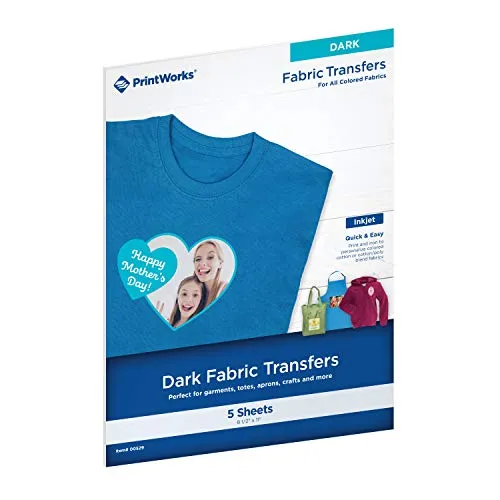

The product is ideal for creating custom printed designs for dark-colored fabric.

|

|

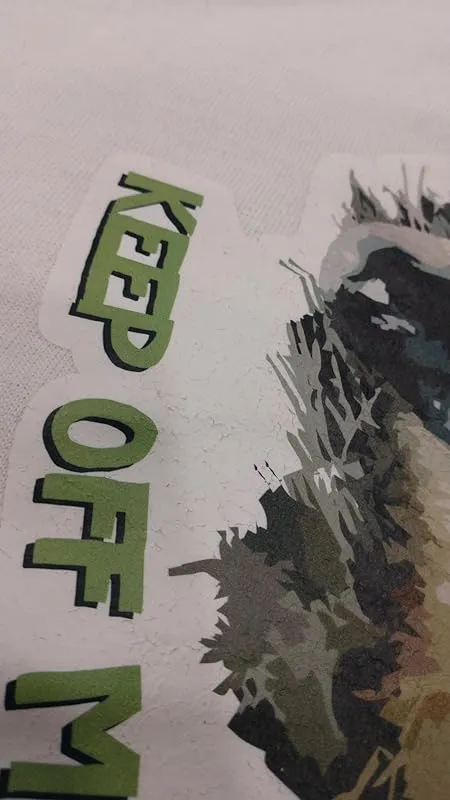

1. Printworks Inkjet Dark T-Shirt Transfers – 40 Sheets

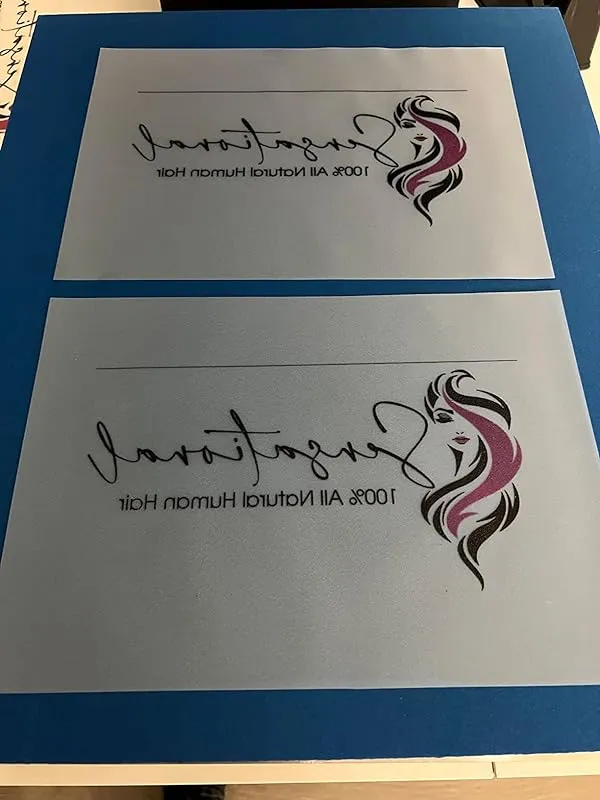

I have had the pleasure of using this transfer paper and I must say, it is one of the best brands out there. In my opinion, it surpasses Avery in terms of quality and performance. This has become my go-to transfer paper for both light and dark fabrics, eliminating the need to buy separate sets for different colored materials.

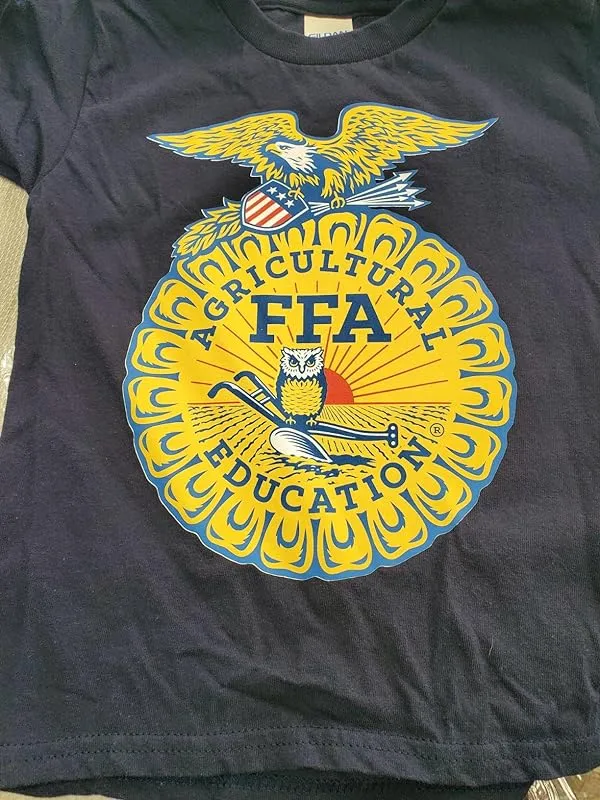

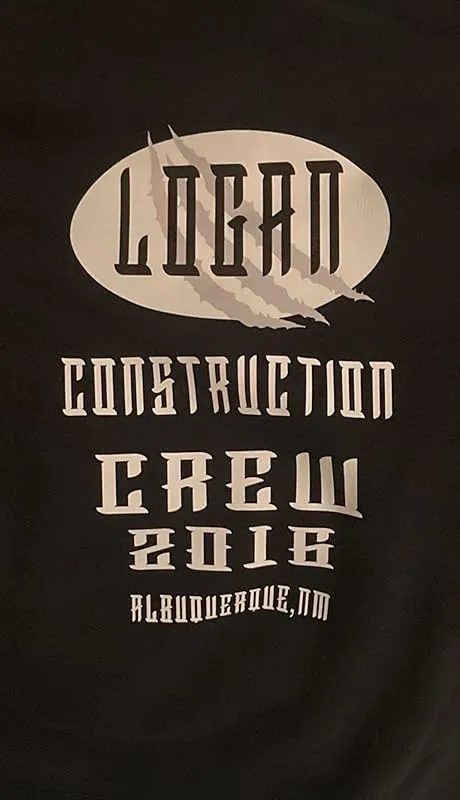

Following the instructions provided, I was able to achieve vibrant and crisp designs on my shirts. My crew was extremely pleased with the logo I designed and how professional it looked. While I can't speak on the durability of the transfers just yet, they seemed to have a strong bond with the fabric threads, giving me hope that they will last.

My husband also had a great experience using this transfer paper. He followed the instructions carefully and was able to print his best friend's face for an ugly sweater contest. The end result was simple yet long-lasting, seamlessly blending with the sweater fabric.

Personally, I love this transfer paper. I have used it multiple times with my cricut Maker without encountering any issues. Whether I'm creating basic or intricate designs, this transfer paper consistently delivers perfect results. In fact, I am planning to purchase a second pack soon, as my first one is almost finished. The included picture showcases my ability to print and cut six small designs separately, with no difficulties in peeling or ironing them onto the fabric.

Having used this product approximately 100 times, I can confidently say that I am in love with it. Previously, I was using Avery transfer paper, which was great but quite expensive. This brand serves as an excellent alternative, providing both affordability and quality. I have successfully used it with my cricut every time. Just remember, when washing the garment, do so inside out and avoid drying it in the dryer. Additionally, refrain from using any fabric softeners.

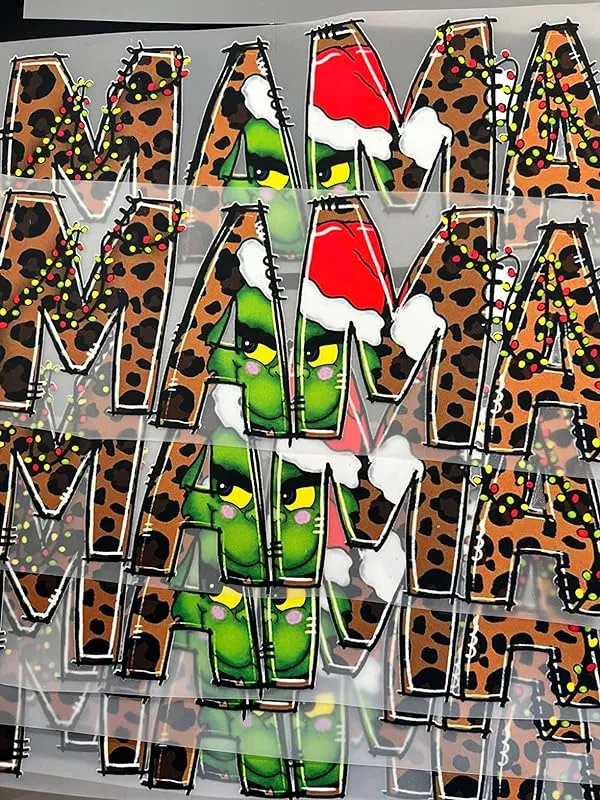

2. Ngoodiez Dtf Powder: Easy Direct Transfer Adhesive

I am extremely impressed with this powder. Not only does it provide excellent adhesion to the ink, but it also lasts for a significant number of prints. I have already printed close to 100 prints and there is still plenty of powder left. The process itself is incredibly easy and hassle-free. I have encountered no issues whatsoever. I highly recommend this product to anyone in need of a reliable printing powder.

Furthermore, I must commend the exceptional customer service provided by this company. When I encountered a problem with my order, they handled it promptly and efficiently. Their dedication to customer satisfaction is truly commendable. As a result, I will definitely be ordering from them again in the future. Their product not only works perfectly but their commitment to their customers is unparalleled.

Although I have only been using this powder for a couple of weeks, I have not encountered any problems thus far. The only minor inconvenience is that it is not available in larger quantities. This is unfortunate as I would like to have more powder on hand for experimentation purposes. However, the powder itself works flawlessly with the DTFPro ink, and I have experienced no issues with separation or clumping. To ensure the longevity of the powder, I have been storing it with dessicant as an extra precaution.

However, I must provide an update on my experience. After persisting with this process for two weeks, I have experienced a significant increase in failures after washing. It appears that the recommended temperatures and times are too high, resulting in damage to the ink. This can be seen in the second photo, which shows the outcome after a normal wash with Tide Free and low tumble dry. Unfortunately, the results have been less than satisfactory.

Initially, I was skeptical about this process. However, I am pleased to say that it has proven to be quite effective. I conducted a sample test and washed it three times, yet there was no fading whatsoever. This has truly been a game changer for me, and I am excited to continue exploring the possibilities of this printing method.

Lastly, I wanted to mention that I used this DTF powder and DTF paper with Sublimation Ink, and successfully transferred onto a white cotton T-shirt. The results were excellent, and I am thrilled with the outcome.

3. Tru-Iron T-Shirt Transfers: Inkjet Printable Heat Transfer For Dark Fabric

I have to say, these printable iron-on sheets are absolutely fantastic. Unlike other brands I've tried before, these sheets don't fade away after just a few washes. They have proven to be extremely durable and long-lasting.

One of the things I love about these sheets is how well they work with my Cricut machine. The print and cut feature is flawless, allowing me to create intricate designs with ease. I've already purchased 10 packs of these sheets and I plan on buying more in the future because they are simply amazing.

The color payoff on these sheets is outstanding. Once the ink is dry and I press it onto fabric, the colors really come to life, almost like sublimation printing. It's truly impressive. Additionally, the sheets are thin yet flexible, which makes them very comfortable to wear.

I have used these sheets to create designs on multiple t-shirts and I've worn them throughout the entire winter season. Even with regular washing, the designs have not faded or come off. I do take care to wash them inside out and hang dry, which I believe contributes to their longevity. The colors on the shirts are just as vibrant as the day I made them.

4. Glossy Clear Dtf Transfer Film – Premium Pet Heat Transfer Paper

I have tried several products in the past, including this one and another one, and I must say that this product stands out as one of the best. The quality is excellent and it exceeded my expectations. The only downside is the price, which is a bit higher compared to other similar products. However, I only purchase this product when my regular vendor runs out of stock because it is worth the extra cost.

The DTF Film sheets that I received were in perfect condition, just as I had imagined. They are highly recommended as they deliver on their promise of glossy and vibrant colors. The DTF glue provided with the sheets melts quickly and easily, resulting in flawless prints. I had no difficulties using these film sheets, they were user-friendly and produced great results.

5. Jack's Iron-On Heat Transfer Paper: Dark Fabric Edition

I recently purchased the 13 by 19 and 11 by 17 sizes of this paper for my 7720 printer, and I must say, I am extremely satisfied with the performance. The paper feeds smoothly without any issues, and I was able to complete my entire package of 13 by 19 without any feed problems. Additionally, I was pleasantly surprised to find that there was no color bleed through the back of the paper.

I have used this paper for various purposes such as printing on fabric, MDF, slate, metal, and glass, and the colors and detail always come out great. The prints are vibrant and the level of detail is impressive. It has definitely met my expectations in terms of quality.

I specifically purchased these transfers to create my son's Halloween costume, and I found them to be incredibly easy to use. The process was hassle-free, and the end result was fantastic. I highly recommend these transfers to anyone looking for an effortless way to create unique costumes or designs.

Moreover, I am really impressed with the overall quality of this paper. It consistently delivers excellent results and does not cause any printer jams, which is a huge plus. I have had no issues whatsoever with its performance, and I would highly recommend this sublimation paper to others.

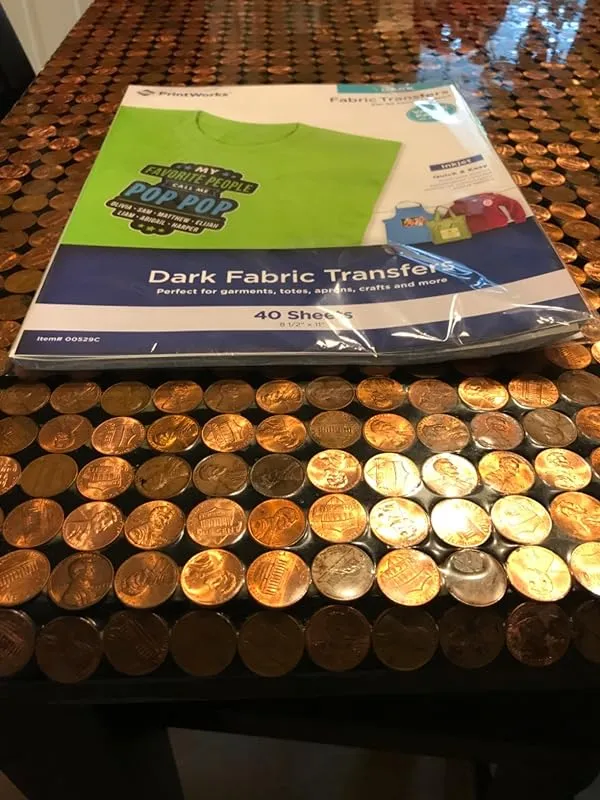

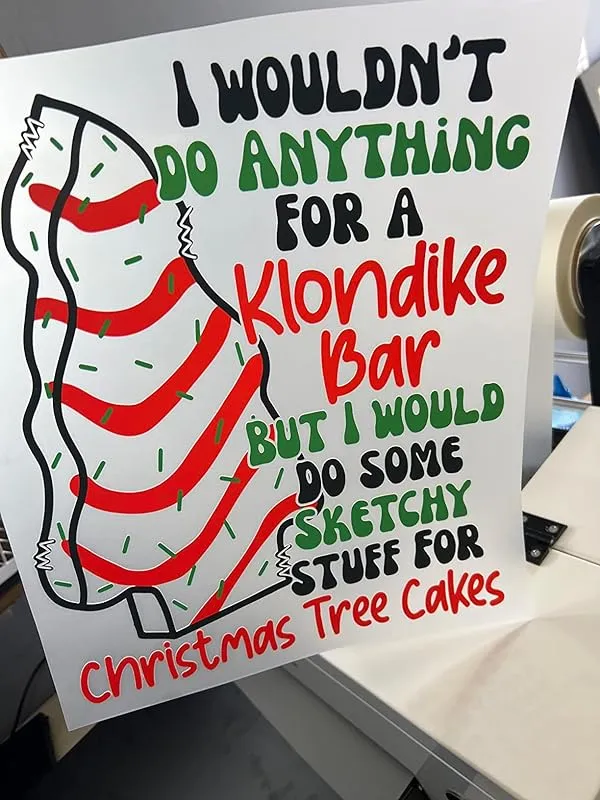

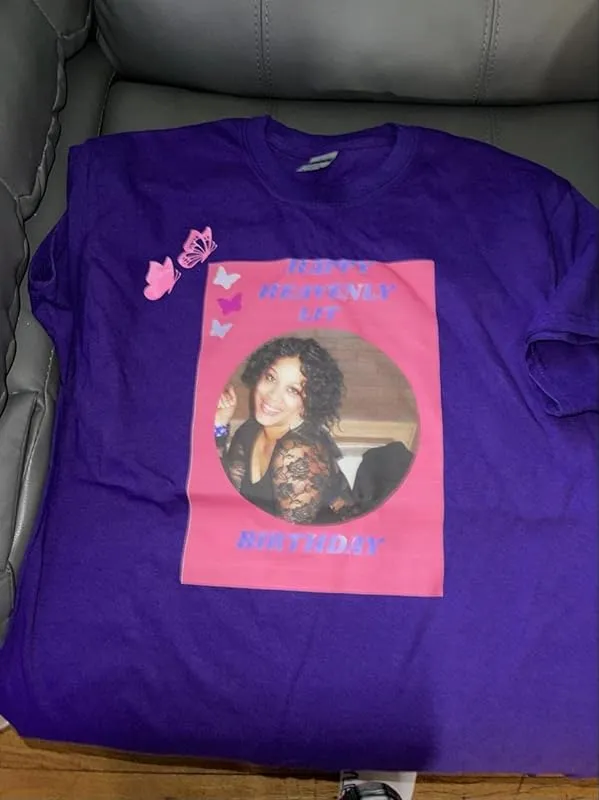

6. Inkjet Printworks Dark T-Shirt Transfers: Diy Christmas Crafts

I recently purchased these transfer sheets and overall, I am quite satisfied with my experience. I have not yet washed the shirts that I applied the transfers to, but I plan to do so soon and will update my review accordingly.

The transfer sheets were easy to use and I found them to be user-friendly. I had done a lot of research prior to purchasing them and was unsure if my next plan would affect the transfer, so I decided to let it cure for 24-48 hours.

Upon washing the shirts, I made sure to turn them inside out and waited for a couple of days before drying them. However, I made a mistake by using the dryer instead of hanging them to dry, which resulted in the shirt shrinking. Despite this, the transfer itself remained intact and looked perfect.

I initially came across these transfer sheets on YouTube and decided to give them a try. It turned out to be the best decision I made. Printing on the sheets and cutting them out was a breeze, and they applied easily with my heat press. The transfers I made were super stretchy, which is a great feature.

After the first wash, the transfers held up well, but I still need to wash them a few more times to see how they fare in the long run.

The package comes with 5 sheets of transfer paper and the special paper that needs to be placed over the transfer when ironing. One important tip to remember is to leave the paper on while the transfer cools down. I unfortunately forgot this instruction with my first transfer, which affected the outcome.

I purchased these transfer sheets specifically to make iron-ons for a Halloween costume, and they worked perfectly on both white and dark green fabrics. I also used them to make shirts for my younger brother on yellow and medium green fabrics. The white color in the design appeared opaque and as intended, unless I ironed it for too long. The fastest ironing job actually turned out to be the best.

In terms of washing, the clothes we decorated washed well. We followed our normal washing routine and then hang dried them.

The colors on the transfers looked a bit light after printing, but once they were transferred onto the shirts, they really popped and looked fantastic. I particularly love that there is no need to flip the image.

Regarding the reviews mentioning difficulty in removing the backing, I found it to be quite simple. Just gently brush the edge from the paper side forward, and it will start to peel away. From there, you can gently remove the backing.

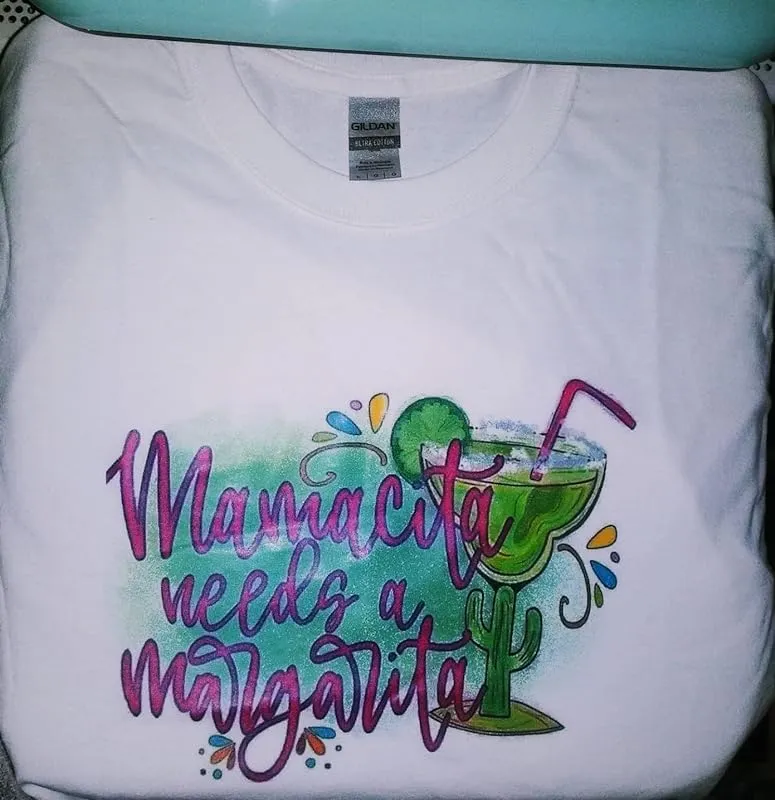

I used these transfer sheets for my initial project, and they worked so well that I volunteered to make shirts for another event. They were a huge hit, and the transfers held up well even after multiple washes. I will definitely be purchasing more of this product in the future.

7. Vibrant Dark T-Shirt Heat Transfer Paper – 30 Pack

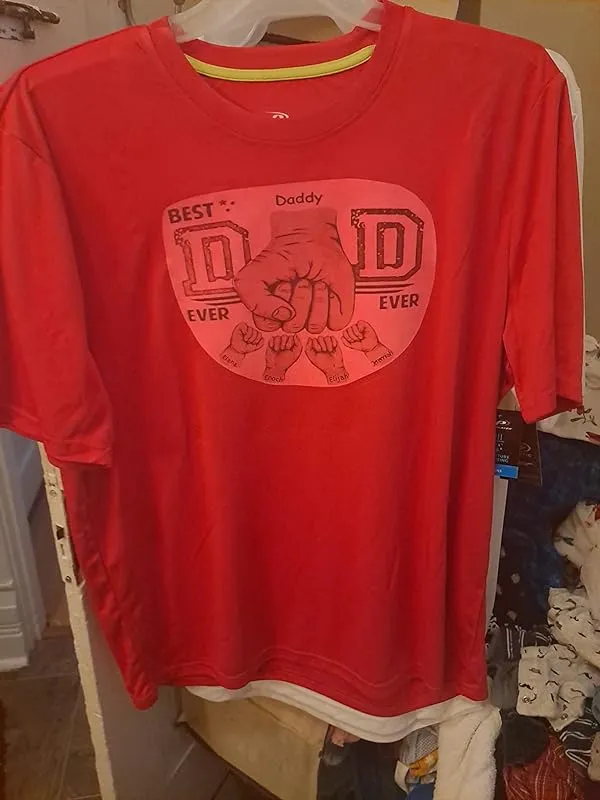

I recently had the opportunity to try out this sublimation product, and I must say it was a breeze to use. As someone who is new to sublimation, I found it much easier to work with compared to a sublimation printer.

The process was straightforward. I designed my artwork in Cricut Design Space, creating a print then cut image. I made sure to add a black offset for the strawberry image and a white offset for the Steelers logo. The best part is, there's no need to mirror the design.

Following the provided instructions, I printed the design on plain paper using the "Best" setting. I then used my Cricut Maker to cut out each design, being careful when peeling the vinyl off the backing. The vinyl was securely attached to the backing, so caution is required during this step.

Next, I placed the image on the material and added the included parchment paper on top. Using my Cricut Easy Press, I applied heat to adhere the design to a canvas bag and a 100% cotton t-shirt. The recommended temperature range is 335º to 338º, and although my Easy Press only allowed increments of 5º, I heated it at 340º and the design adhered perfectly without any iron imprints.

Once the image was on the products, it felt smooth and silky, without any stiffness or thickness. The end result was impressive, and I was glad I decided to give this product a try. It's worth mentioning that I used a Brother EcoTank 3850 with regular ink, not sublimation ink.

I also had the opportunity to make class shirts for my mom's class reunion. Before taking the order, I decided to experiment by making a shirt for myself first. To address the concern of peeling, I made sure to let the ink dry for at least 45 minutes after printing but before cutting. Additionally, I "cured" the shirts by hanging them up in my closet for 2 days.

The result was fantastic. The design didn't peel, even after washing the shirt multiple times (at least 5 times before taking the picture). I even accidentally spilled coffee on it, and the colors didn't run. While I recommend customers to wash the shirts on delicate in cold water, I accidentally washed the one I made for my daughter on a normal cycle in cold water, and it held up perfectly fine.

The only cautionary note I have is to avoid drying the shirts in a dryer, as the heat could cause the design to peel. I personally hang dry all the vinyl shirts I made, including the ones for myself and my daughter.

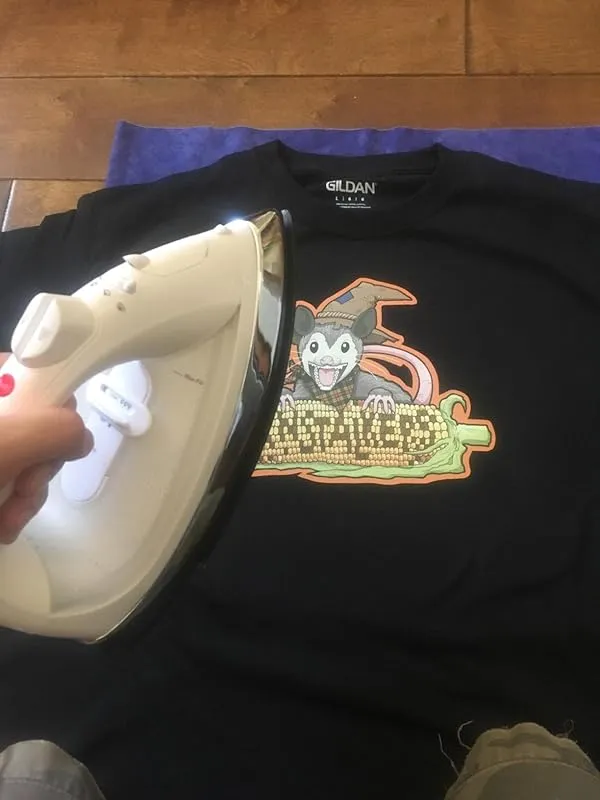

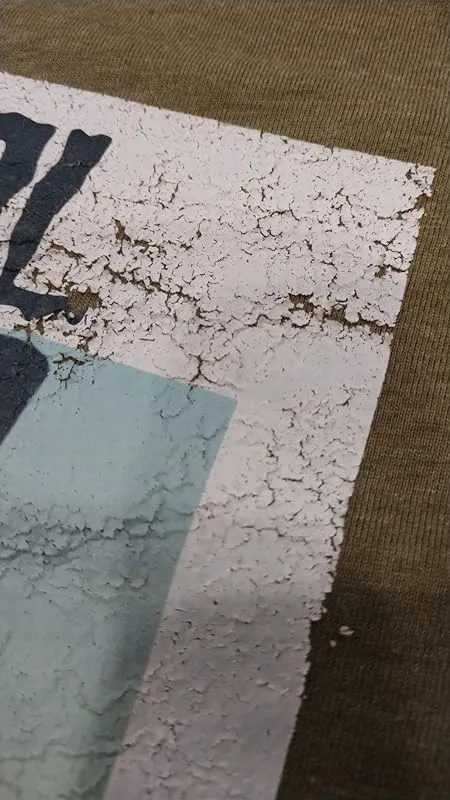

8. Usa-Made Non-Toxic Iron-Ons: 25 High-Quality Dark Fabric Sheets

After using this vinyl for multiple washes and runs in the dryer, I have found that it still maintains its vibrant colors and overall quality. The vinyl may still be a bit stiff, but that does not affect the appearance or durability of the design. I initially had some doubts due to previous reviews mentioning durability and fading, but I am pleased to report that my experience has been positive.

I printed the design with my inkjet printer on high-quality settings, and the image turned out vibrant and wonderful. I followed the recommended instructions by pressing the vinyl at 320 degrees for 30 seconds and then washing it in hot water and drying it at the highest heat setting. The design came out just fine and showed no signs of peeling or damage.

Based on my experience, I believe that the peeling issues mentioned by other customers may be a result of insufficient pressure when using an iron. I plan to continue washing the vinyl at least 10 more times to further test its durability, but so far, it has held up exceptionally well. I will update if there are any changes, but for now, I am confident that this vinyl is of great quality.

I must admit that I was pleasantly surprised by this vinyl, as I initially believed that the only way to achieve a wide range of colors and specific designs was through HTV or sublimation, which can be quite costly. As someone who is just starting out and creating designs for myself and my family, this vinyl has been a great find for me. I was able to recreate specific designs for my husband, who works in the film industry and receives film memorabilia from his job. One of his favorite sweatshirts was deteriorating, so I redesigned it using this vinyl, and the results were fantastic. I am very happy with the outcome.

While I cannot speak for the long-term durability or the test of time, I can confidently say that this vinyl looks great for now. I highly recommend it based on my current experience. If anything changes in terms of durability or performance after further washes, I will make sure to update this review.

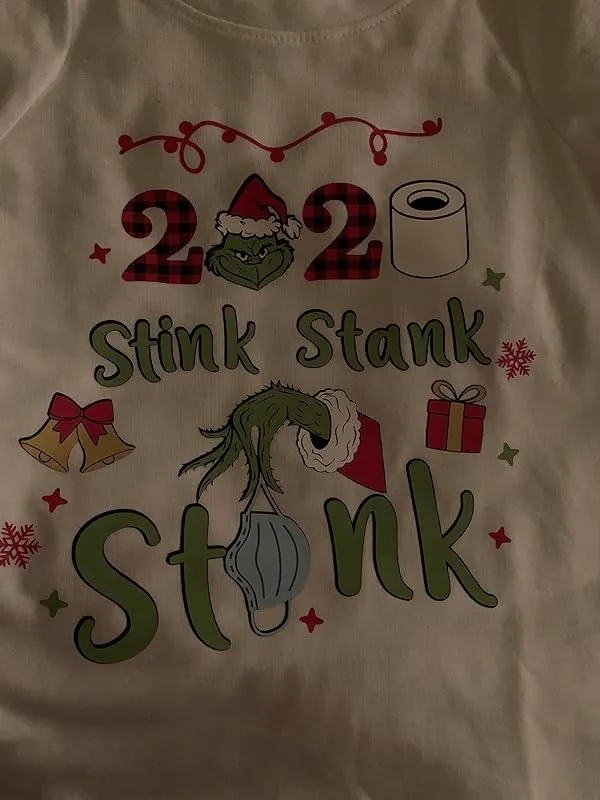

It is worth mentioning that I had initially purchased this product about six months ago and had forgotten about it until recently when my children's daycare had a "Grinch Day" for spirit day, and I couldn't find any Grinch-themed clothing in their sizes. I ended up purchasing SVG/PNG files from Etsy and found that using this vinyl was much easier than I had anticipated. I did encounter some difficulties with fine snowflakes being lost during the cutting process, and aligning certain words was a bit challenging, but overall, this product proved to be simple to use and affordable.

Assuming that the wash goes well, I will definitely consider purchasing more of this vinyl in the future. However, I'm not overly concerned about the longevity of the designs on these particular shirts since I bought them on sale for a low price and they are unlikely to be used again.

9. Brilliantly Durable Pet Heat Transfer Films | 60 Sheets

I recently had the opportunity to try out this product and I must say, it is truly amazing. I tested it on both dark and light colors and it worked perfectly with my sublimation printer. The results were outstanding and I couldn't be happier. I highly recommend this product to anyone in need of a reliable DTF film.

Out of all the DTF films I have used, this one is by far the best. I have tried three different brands before and none of them compare to the quality and performance of this film. The only downside is that I wish they offered a larger size option, as it would be more convenient for bigger projects.

Using this transfer film was a breeze. It was easy to apply and once heated, the image transferred flawlessly onto the fabric. The end result was exactly what I was hoping for. I can confidently say that this transfer film is of top-notch quality and I highly recommend it to others.

I had a fantastic experience using this film. The prints came out bright and vibrant, and they cured perfectly. The transfer process was seamless and I was able to complete my shirts with ease. I can't think of a single thing that went wrong during the entire process. It was simply perfect!

I have found a great hack using this film for sublimation projects. By cutting it to the size of my project and adhering it to a piece of copy paper with blue painters tape, I am able to run it through my sublimation printer. I have only encountered one minor issue with smearing ink, but I don't blame the film for that. To complete the process, I add the powder while the ink is still wet and then cure the film using a heat press. The results have been outstanding, and I have successfully used it on various fabric compositions such as 50/50 cotton poly and 100% cotton.

10. Tru-Iron Dark Fabric Heat Transfer Paper: Inkjet Print, 15 Sheets

I recently used this product to create a shirt for a friend who had successfully beaten cancer. The process went smoothly, although I did make a mistake by flipping the image before printing it, resulting in some wasted sheets. However, the final outcome turned out great, and the shirt is still holding up well. I would definitely consider using this product again for future shirt designs.

One aspect that I particularly liked about this product is its texture. It easily adheres to the fabric of the shirt, making the application process hassle-free. This feature came in handy when my family decided to create matching shirts for our reunion. We used the same design on shirts of various colors, both light and dark. The print quality was satisfactory, and the ironing process worked well. Only a couple of shirts experienced slight peeling, even after being washed. However, I did notice that the color on the print started fading after a few washes, which was a minor drawback.

FAQs

Are fabric printers able to print detailed or intricate designs on fabric?

Yes, fabric printers are capable of printing detailed and intricate designs on fabric. With advancements in technology, fabric printing has become more sophisticated and versatile. Digital fabric printing, in particular, allows for extremely detailed designs to be printed on various types of fabrics.

Fabric printers use high-resolution printing techniques that can accurately reproduce intricate patterns, fine lines, and small details. They can achieve this level of precision by using advanced inkjet technology and specialized printing software.

Additionally, fabric printers offer a wide range of color options, allowing for vibrant and rich designs to be printed on fabric. They can also print on various fabric types, including cotton, silk, polyester, and more.

It is important to note that the quality of the design and the level of detail achievable may also depend on factors such as the quality of the artwork provided, the type of fabric being printed on, and the expertise of the printer operator.

Therefore, it is recommended to work with professional fabric printers who have experience in handling intricate designs and can provide guidance on optimizing the printing process for the best results.

Are fabric printers capable of printing in full color?

Yes, fabric printers are capable of printing in full color. With advancements in digital printing technology, fabric printers can now reproduce vibrant and detailed designs in a wide range of colors. These printers use specialized inks and advanced color management techniques to achieve accurate color reproduction on various types of fabrics.

The printing process involves creating a digital image or design, which is then transferred onto the fabric using the printer. The ink is specifically formulated to bond with the fabric fibers, resulting in long-lasting and vibrant colors.

Fabric printers can produce high-resolution prints with intricate details, gradients, and a full spectrum of colors. Whether it's for textiles, fashion, home decor, or promotional materials, fabric printers offer the versatility and capability to bring full-color designs to life on various fabric surfaces.

Are fabric printers suitable for both personal and commercial use?

Yes, fabric printers are suitable for both personal and commercial use. Fabric printing technology has advanced significantly in recent years, making it more accessible and affordable for individuals and businesses alike.

Personal users can utilize fabric printers to create custom designs for their own clothing, home decor, or craft projects. On the other hand, commercial users, such as fashion designers, textile manufacturers, and printing businesses, can benefit from fabric printers to produce large quantities of high-quality printed fabrics for various purposes, including apparel production, interior design, promotional items, and more.

Fabric printers offer versatility and the ability to print on a wide range of fabrics, allowing users to unleash their creativity and meet their specific needs. Whether for personal or commercial use, fabric printers provide a convenient and efficient solution for printing vibrant and customized designs on fabric.

Can any printer be used for printing on fabric, or do you need a specific fabric printer?

While it is possible to print on fabric using a regular printer, it is not recommended due to various reasons. Regular printers are designed to work with paper and are not equipped to handle the unique characteristics of fabric.

Printing on fabric requires specialized printers known as fabric printers.

Fabric printers are specifically designed to print on various types of fabrics, ensuring high-quality and long-lasting results. They are equipped with features such as fabric feeding systems, specialized ink formulations, and heat settings that are essential for proper adhesion to the fabric.

Using a regular printer for fabric printing may result in poor print quality, ink bleeding, smudging, and fabric damage. Additionally, regular printers may not be compatible with fabric materials, thicknesses, or sizes.

If you are looking to print on fabric, it is highly recommended to invest in a fabric printer. These printers are designed to deliver optimal results and ensure that your fabric prints are vibrant, durable, and professional-looking.

Can fabric printers print on different types of fabric, such as cotton, silk, or polyester?

Yes, fabric printers are capable of printing on different types of fabric, including cotton, silk, and polyester. These printers utilize various printing technologies such as dye sublimation, direct-to-garment (DTG) printing, and heat transfer printing, among others.

Each technology is suitable for specific fabric types.

Dye sublimation printing is commonly used for polyester fabrics as it involves transferring dye onto the fabric using heat. This process allows the ink to permeate the fabric, resulting in vibrant and long-lasting prints.

DTG printing is ideal for cotton fabric as it involves digitally printing the design directly onto the fabric using specialized inkjet printers. This method provides high-resolution prints with intricate details.

Silk fabric requires delicate handling, and screen printing is often used. This technique involves applying ink through a fine mesh screen onto the fabric, allowing for precise and intricate designs.

It is important to note that different fabrics may require specific pre-treatments or post-treatments to ensure optimal print quality and durability. Therefore, it is recommended to consult with a professional fabric printing service to ensure the best results for each fabric type.

How long does it take for a fabric printer to print a design on fabric?

The time it takes for a fabric printer to print a design on fabric can vary depending on several factors.

Firstly, the complexity of the design plays a significant role. More intricate and detailed designs may require a longer printing time compared to simple patterns or solid colors.

Secondly, the size of the design and the fabric itself can affect the printing duration. Larger designs or printing on larger pieces of fabric will naturally take more time.

Thirdly, the type of fabric being used can also impact the printing time. Different fabrics require different printing techniques and processes, which can influence the overall printing duration.

Lastly, the efficiency and speed of the fabric printer being used will contribute to the printing time. Some advanced machines are capable of printing at a faster rate than others.

In general, fabric printers can take anywhere from a few minutes to several hours to complete the printing process. It is best to consult with the fabric printer manufacturer or service provider for a more accurate estimate based on your specific requirements.

What is the maximum size of fabric that can be printed on a fabric printer?

The maximum size of fabric that can be printed on a fabric printer can vary depending on the specific printer model and its capabilities. However, in general, fabric printers are capable of printing on fabrics of various sizes, ranging from small pieces to large rolls.

For small-scale fabric printers such as desktop or tabletop models, the maximum printable area is typically limited to the size of the printer's platen or bed. This can range from a few inches to a couple of feet in width and length.

On the other hand, industrial fabric printers used in large-scale production can handle much larger fabric sizes. These printers are designed to accommodate fabric rolls of different widths, which can vary from a few inches to several meters wide.

The length of the printed fabric can be several meters or even longer, depending on the printer's capabilities and the requirements of the printing job.

It's important to consult the specifications provided by the manufacturer or supplier of the fabric printer to determine the specific maximum size that can be printed on a particular model.

What is the resolution or DPI (dots per inch) of a fabric printer?

The resolution or DPI (dots per inch) of a fabric printer can vary depending on the specific model and technology used. Fabric printers typically have a lower DPI compared to traditional paper printers due to the nature of printing on fabric.

The resolution can range from 300 DPI to 1200 DPI or even higher in some advanced models.

The DPI of a fabric printer determines the level of detail and sharpness in the printed design. Higher DPI results in more precise and intricate prints, while lower DPI may lead to slightly less detailed output.

It is important to note that fabric printing involves different considerations than printing on paper, such as ink absorption and fabric texture, which can affect the final print quality.

To determine the exact DPI of a specific fabric printer, it is best to refer to the manufacturer's specifications or consult with a professional fabric printing service provider. They can provide accurate information and guidance based on your specific printing requirements.

What type of ink is used in fabric printers?

Fabric printers typically use specialized inks called textile inks or fabric inks. These inks are specifically formulated to adhere to fabric fibers and withstand the rigors of washing and wearing. They are designed to provide vibrant and long-lasting colors on various types of fabrics, such as cotton, polyester, silk, and blends.

Textile inks are available in different forms, such as pigment inks, dye-based inks, and sublimation inks. Pigment inks contain tiny particles that sit on top of the fabric surface, providing excellent color saturation and durability.

Dye-based inks, on the other hand, penetrate the fabric fibers, creating vibrant and softer colors. Sublimation inks are used for heat transfer printing, where the ink turns into a gas and bonds with the fabric when exposed to heat.

The specific type of ink used in fabric printers depends on the printing method, fabric type, and desired outcome. It is essential to choose the right ink for optimal color vibrancy, washability, and longevity.

What type of printer is best for printing on fabric?

When it comes to printing on fabric, there are a few types of printers that are commonly used. The best type of printer for fabric printing depends on your specific needs and requirements.

One popular option is inkjet printers, which use liquid ink to produce high-quality prints. Inkjet printers are versatile and can handle different types of fabric, including cotton, silk, and polyester. They offer excellent color reproduction and can print intricate designs with fine details.

However, it's important to note that inkjet printing may require pre-treating the fabric with a fixative or coating to ensure the ink adheres properly.

Another option is dye-sublimation printers, which use heat to transfer dye onto the fabric. This method produces vibrant and long-lasting prints, especially on synthetic fabrics like polyester. Dye-sublimation printing allows for full-color prints and is often used in the production of custom clothing, banners, and promotional items.

If you're looking for a more cost-effective option, you can also consider using a heat transfer printer. These printers use heat to transfer designs from special transfer paper onto the fabric. While the quality may not be as high as inkjet or dye-sublimation printers, they are suitable for small-scale projects or personal use.

Ultimately, the best printer for fabric printing depends on factors such as budget, intended use, and desired print quality. It's advisable to research and compare different models, read customer reviews, and consult with professionals in the field to make an informed decision.