I Tested And Reviewed 8 Best Stepper Motors For 3D Printer (2023)

Choosing the right stepper motor is crucial for getting the most out of your 3D printer. With so many options on the market, it can be tricky to know where to start. But don't worry, in this article we'll walk you through the key factors to consider when shopping for the best stepper motors for your specific needs.

First, you'll want to think about the torque rating. Torque determines how much force the motor can exert. Higher torque motors can handle heavier loads and print materials like wood filament more easily. But you don't want to go overboard either, as too much torque can cause issues. Find the sweet spot based on your printer setup and typical use cases.

Next, consider the step angle resolution. Stepper motors move in discrete steps, and the step angle indicates how precise those steps are. Lower step angles allow for finer motions and more detailed prints. Step angles of 1.8 or 0.9 degrees are common in 3D printing.

You'll also want to make sure the motor is properly sized for your application. The NEMA standard provides sizing specs, with higher numbers corresponding to larger motors. NEMA 17 motors are the most common for desktop 3D printers.

Lastly, factor in features like silent operation. Integrated dampers and drivers optimized for quieter printing may be worthwhile upgrades over standard motors.

Doing your homework on stepper motors will pay off with smoother, higher precision printing. For more guidance on choosing the right model, check out our top picks and in-depth reviews of the best stepper motors for 3D printers. Happy printing!

8 Best Stepper Motors For 3D Printer

| # | Product Image | Product Name | Product Notes | Check Price |

|---|---|---|---|---|

|

1

|

The product is ideal for providing precise and efficient movement for the X/Y-axis of 3D printers.

|

|

||

|

2

|

The product is ideal for powering the extruder gear of 3D printers such as Ender 3, Ender 3 V2, Ender 3 Pro, Ender 5, and CR-10.

|

|

||

|

3

|

The product is ideal for Prus i3 MK2 MK3 MK3S E Axis 3D printers or CNC machines.

|

|

||

|

4

|

The product is ideal for 3D printers, specifically suitable for Ender 3 V2/Pro, Ender 3 Series, CR10 Series, CR6 Series.

|

|

||

|

5

|

The product is ideal for use in 3D printers and CNC machines, providing precise and controlled movements.

|

|

||

|

6

|

The product is ideal for replacing the stepper motor in Ender 3, Ender 5, CR-10, and CR-10S 3D printers.

|

|

||

|

7

|

The product is ideal for connecting stepper motors to a 3D printer, ensuring smooth and precise movements.

|

|

||

|

8

|

The product is ideal for 3D printing and controlling the axis movements in Creality Ender-3 and CR-10 series printers.

|

|

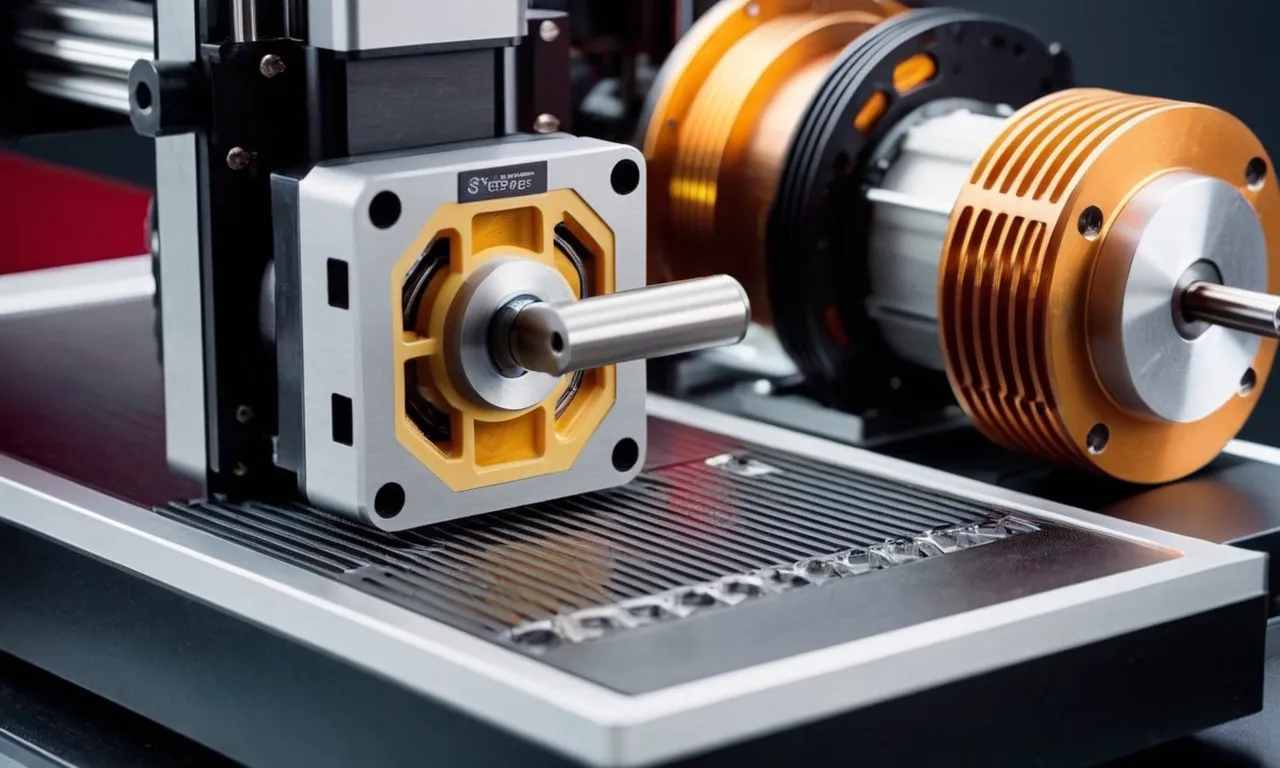

1. Creality Cr-10 X/y-Axis Stepper Motor

The Ender 3 Pro initially came with a stepper motor for the z-axis that did not function properly. However, after ordering the specifically marked z-axis stepper motor, the issue was resolved. It is important to note that the standard 42-34 and the 42-34 z-axis stepper motors have slightly different specifications, which can make a difference in performance. It would have been preferable if the printer had come with the correct stepper motor from the start.

As always, it is recommended to calibrate the x/y/z/e steps before undertaking any critical printing tasks. This ensures that everything works correctly and saves you from potential headaches caused by incorrect calibration.

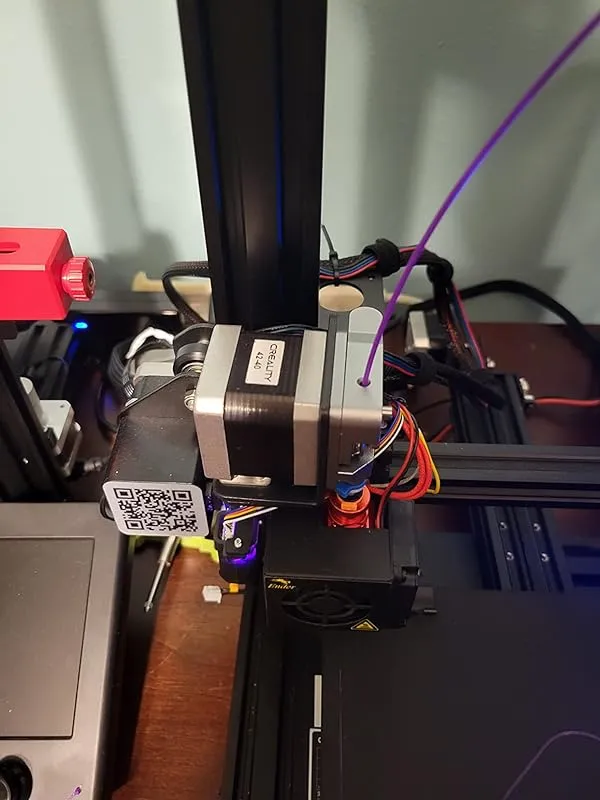

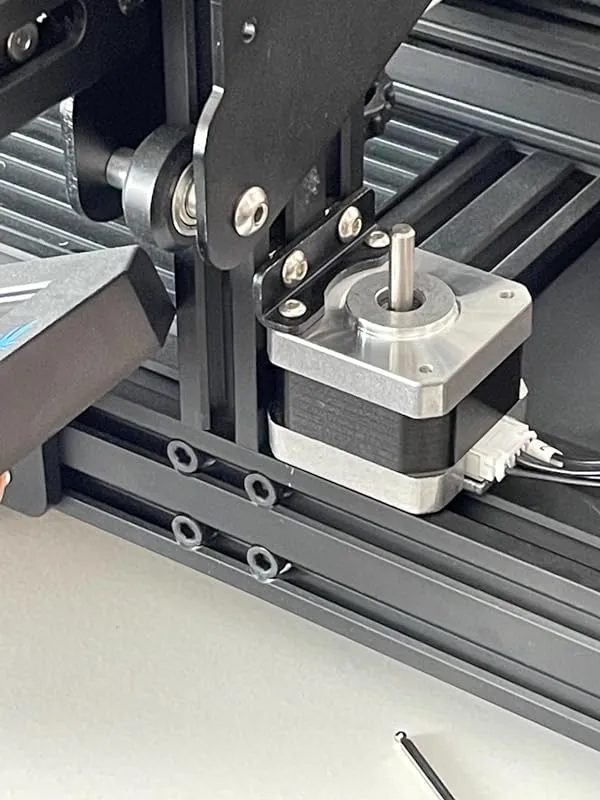

For those using the MS dual gear extruder, this motor is the correct part to use. The extruder requires a D-shaped shaft with a removable gear, whereas some printers, like the CR10 S5, come with a press fit gear and a round shaft on the extruder motor. The 42-40 creality motor with the longer shaft perfectly fits the upgrade requirements and functions just like the motor it replaced.

During the process of adding a new hotend and metal extruder, the tension arm screw may fail to tighten properly, leading to stripped threads in the motor body. Instead of purchasing the original kind that came with the E3 Pro, which has a press fit gear, opting for this motor and a pack of replacement gears proves to be a suitable solution. This motor has been working fine, with no noticeable change in e-steps when using the same filament as before. The ability to easily replace the gear is also a plus, eliminating the need to buy a special puller. Overall, it is a cost-effective upgrade, and considering another one for the E3 Max Neo is worth considering.

This motor is exactly what I needed for my dual gear extruder kit upgrade. Unfortunately, the kit I chose did not mention the requirement for a motor with an extended shaft. Thankfully, this motor has the extended shaft and works perfectly for the upgrade.

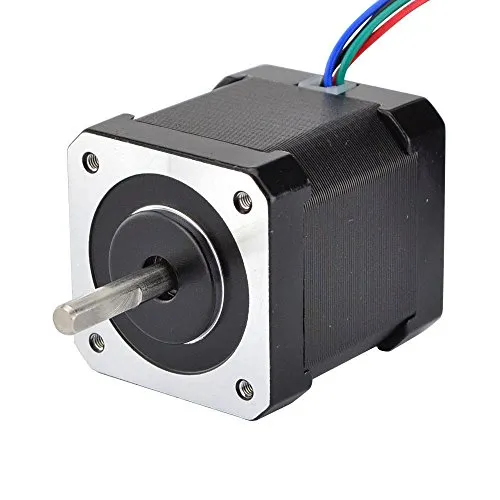

2. Creality 42-40 Stepper Motor: Extruder Gear Powerhouse

I purchased this extruder motor as a replacement for the one that came with my printer. The original motor had the gear securely attached to the rod, making it difficult to modify. However, this motor allowed me to easily upgrade my extruder to a dual gear system.

I was disappointed that Creality does not include this longer-shank motor as the default option with their printers. It seems like a small cost difference, but it forces users to purchase an upgrade when they want to improve their extruder. While it feels like a waste of money or a scam, I must say that this motor itself works great, just like the one it replaces.

The motor was a perfect fit for my Ender 3 Pro and allowed me to seamlessly upgrade to a dual-gear extruder. It also came with the brass extruder gear, which was a must-have for me. I did have to use Pronterface to edit some G code and set my steps, but overall, the motor performed well.

If you're looking to modify your extruder or upgrade to a better system, this motor is a reliable choice. It may require some additional adjustments, but it ultimately gets the job done effectively.

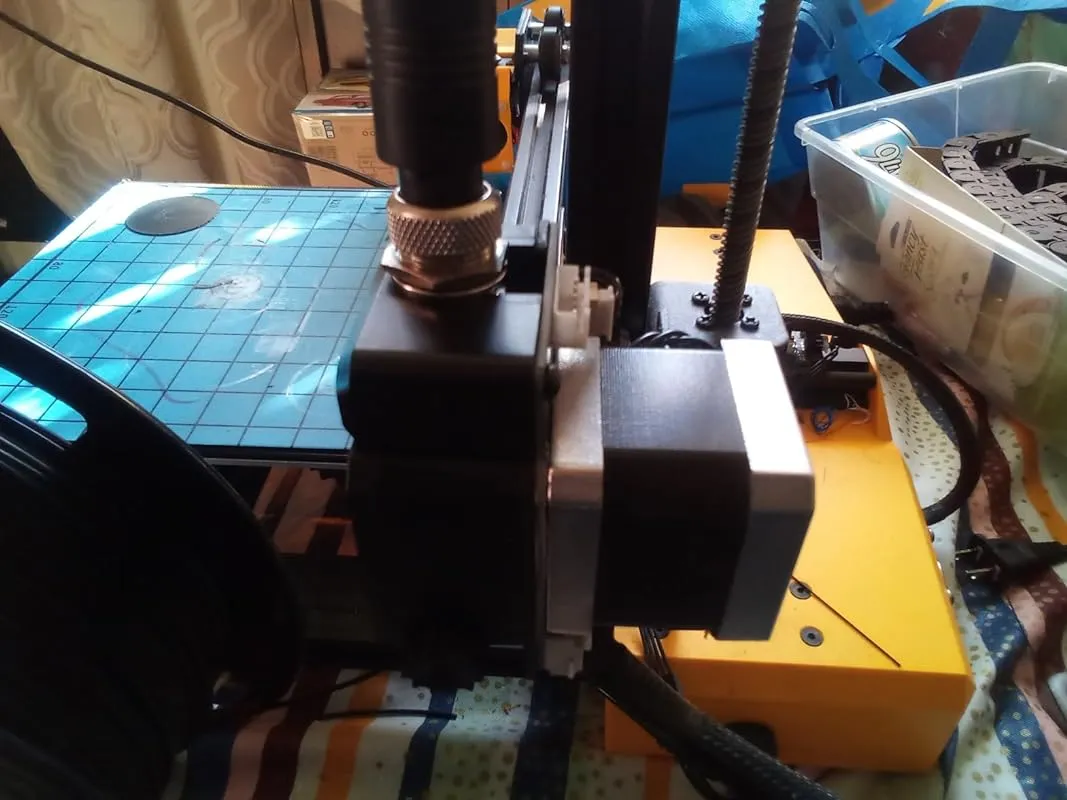

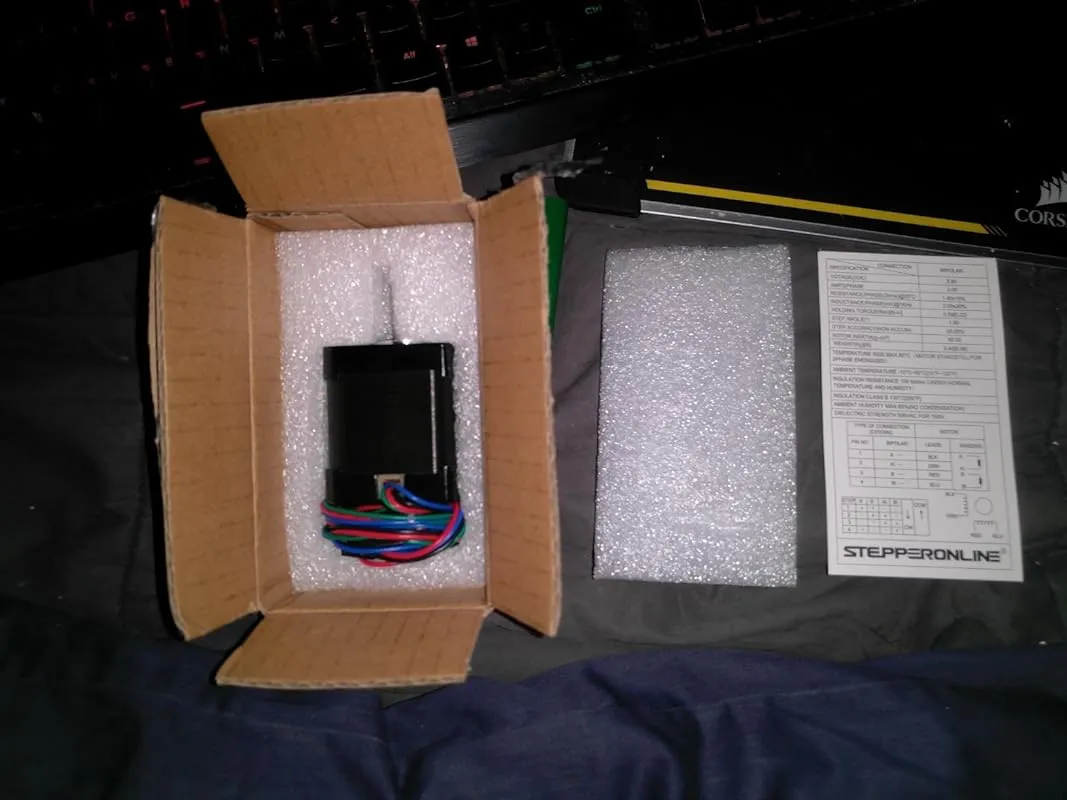

3. Prus I3 Stepper Motor: Compact & Connected

I recently purchased a stepper motor from Prusa and I must say, I am quite satisfied with my purchase. Although the shipping cost to the US was a bit expensive, I decided to go ahead with it because I needed one urgently. To my relief, the motor worked perfectly right out of the box and my filament is moving smoothly again. In fact, I was so impressed with its performance that I ended up buying two more as backups for my other printer. This motor has truly been a lifesaver for me.

One thing I appreciated about this stepper motor is its perfect fit. It seamlessly integrated into my printer and has been working flawlessly for a week now, even with constant printing. While I initially wanted to get the Prusa original, I was in a pinch and had to opt for this alternative. However, I have no regrets as it has exceeded my expectations.

What I found particularly impressive about these steppers is that they serve as perfect replacements for the stock MK3S motors. Apart from the branding stamped on the shell, they are essentially identical to the official ones, but at half the price. I have replaced two different motors with these replacements, and both have been running perfectly without any issues.

I also want to mention that I built a new extruder for my Prusa printer and specifically chose this motor because it perfectly matched the specifications of the one used by Prusa. This further reaffirmed my confidence in the quality and compatibility of this product.

4. Geeetech Nema 42-40 Stepper Motors: Powerful For 3d Printing

After experiencing issues with my previous stepper motor running too hot, I decided to give this new one a shot, and I must say, I am thoroughly impressed. I recently ran my first print at a speed of 100mms, and to my delight, the motor performed flawlessly without overheating.

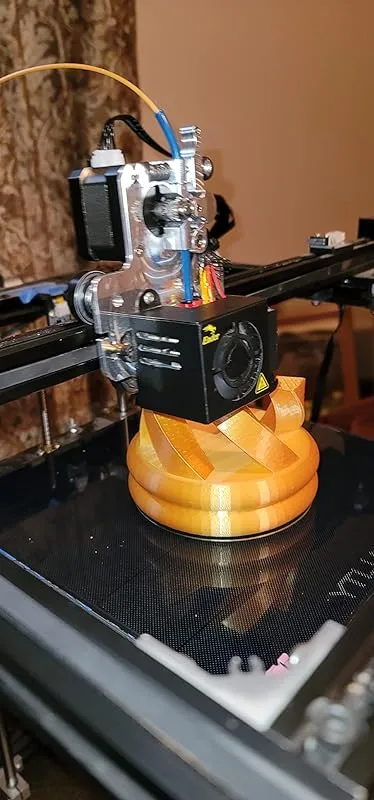

The quality of the print was exceptional, as depicted in the accompanying picture (please note that the filament used in the image is not from Geeetech). I was particularly pleased with the motor's ability to maintain a steady speed throughout the print, resulting in precise and accurate output.

I wholeheartedly recommend this motor to anyone in need of a reliable and efficient solution. Not only does it deliver excellent performance without overheating, but it also ensures a smooth printing experience. Say goodbye to frustrating interruptions and hello to consistent, high-quality prints with this remarkable stepper motor.

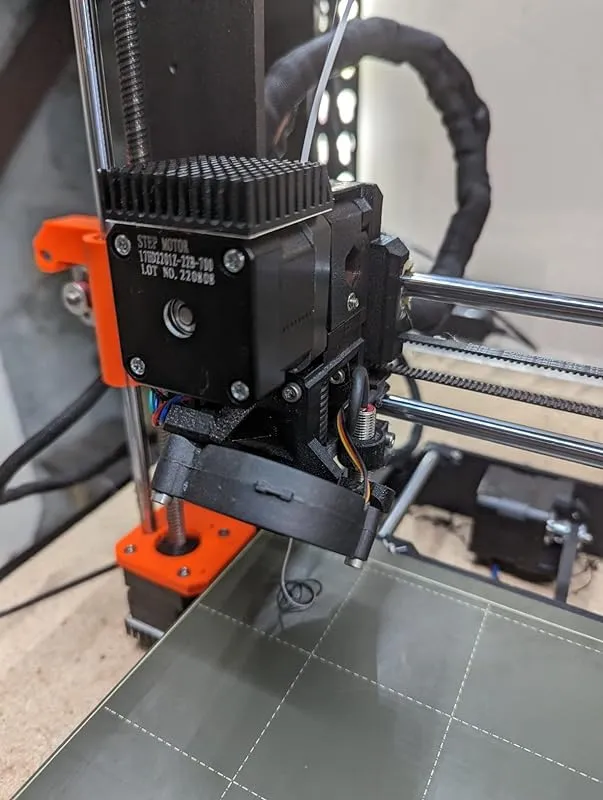

5. Ultra-Power Nema 17 Stepper Motor For 3d Printer/cnc

The NEMA 17 stepper motor is incredibly powerful and exceeded my expectations. I was initially considering upgrading to a NEMA 23 motor, but this motor proved to be more than capable. It can easily drive various 3D printers, CNC routers, and other similar machinery. I tested it at 36 volts and 1 amp, and it remained warm without getting excessively hot.

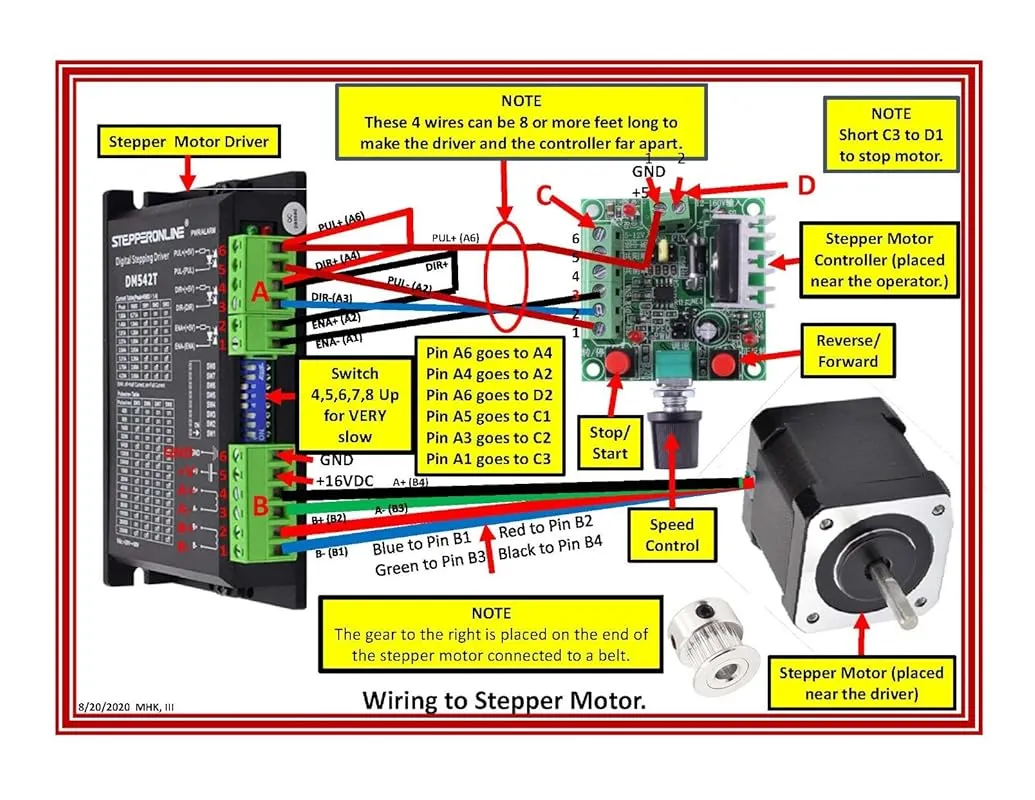

One important thing to note is that the wire color of the motor is not always meaningful. To determine the pairs, simply spin the shaft and touch two wires together. If it becomes more difficult to spin, those two wires are a pair. The other two wires will then form the other pair. This method makes identifying the pairs very simple. It's worth mentioning that it's not uncommon for motor wiring color to be meaningless. Additionally, if you take your motor apart, you risk damaging it, so it's best to avoid doing so.

I've noticed a lot of concern about heat, but it's important to understand that these motors can get quite hot without any issues. If you can't keep your finger on the motor for more than a second without burning yourself, then it's too hot. Otherwise, the heat is perfectly normal.

Changing the spin direction of the motor is easy. You just need to flip any single pair of wires, and the motor will start turning in the opposite direction. If you flip both pairs, nothing will change. Swapping pairs from A to B will also change the direction. Remember, you only need to flip a single pair to alter the direction.

In my case, I was using this motor for a geared extruder on my 2.85mm filament-sized 3D printer. I had previously been using a standard 40mm NEMA 17 motor, but I encountered issues with skipped steps when extruding the larger diameter filament. I had to increase the motor currents beyond the rated amps, yet the skipped steps persisted. This is when I decided to order this stepper motor.

The higher current limit and torque rating of this motor solved my problem. It runs much cooler because I'm no longer supplying it with excessive power, and I can tune it to prevent skipped steps during extrusion. I would definitely consider purchasing this stepper motor again for similar applications. I've even thought about replacing the moving y-axis stepper motors on my 310x310mm bed-sized printers with this motor due to the added stress that such a large print bed puts on the motors.

One thing to keep in mind is to double-check the pinout in the connector to ensure it matches your stepper driver outputs. I had to make some adjustments to the pinout on mine, but this is a common occurrence with 3D printer components. As a maker, this minor inconvenience didn't detract from my overall satisfaction with the motor.

6. Nema17 Stepper Motor For Ender 3d Printers

The Replacement Motor for Creality Ender 3 is an excellent choice for those looking to upgrade their printer's performance. Whether you need to replace a motor with a pressed-on drive pulley or want to reduce weight without compromising functionality, this motor is the perfect solution.

One of the standout features of this motor is its compatibility with various printer models, such as the Creality Ender 3, CR-10S, and more. Users have reported seamless installation and immediate functionality, making it a user-friendly option.

In addition to its ease of use, this motor also offers improved performance. Users have experienced reduced noise levels, thanks to the integration of motor isolators/dampers and new pulleys. This motor operates quietly and efficiently, ensuring a smooth printing experience.

Another advantage of this replacement motor is its reliability. Users have praised its ability to handle heavy-duty tasks without missing a step. Whether you're using it for extrusion or as a servo motor, this product delivers reliable performance consistently.

Moreover, this motor's compact design is an added benefit. It is slightly shorter than stock motors, which not only saves space but also contributes to a more streamlined setup. This feature is particularly advantageous when replacing any of the four servo motors.

To ensure optimal functionality, users have reported adjusting the vref to prevent overheating. This simple adjustment has proven effective in maintaining the motor's performance over extended periods.

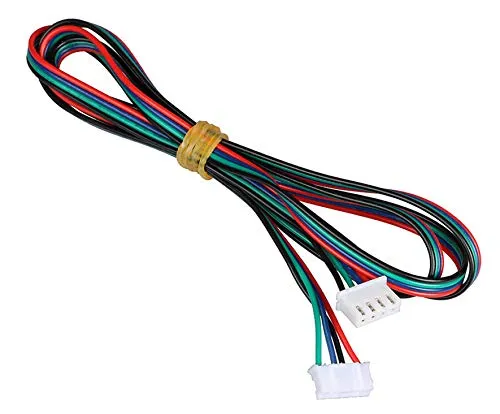

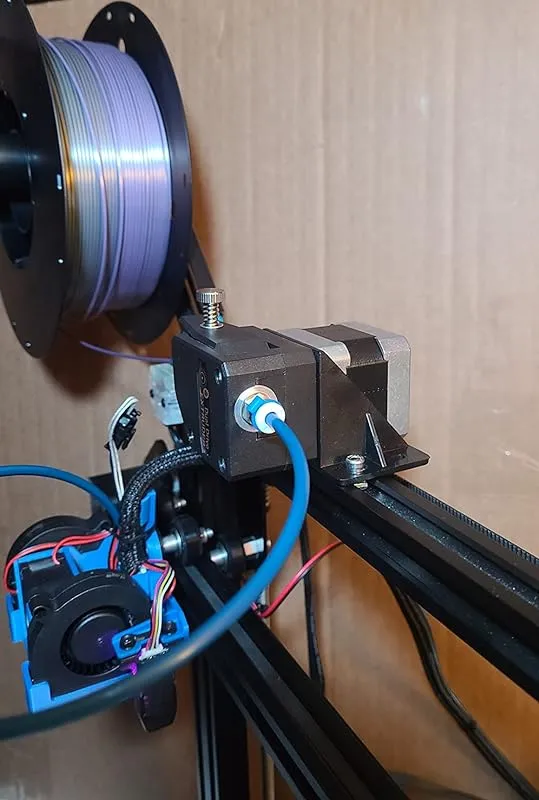

7. Paralled Motor Wires: 6pcs 1.5m Cables For 3d Printer

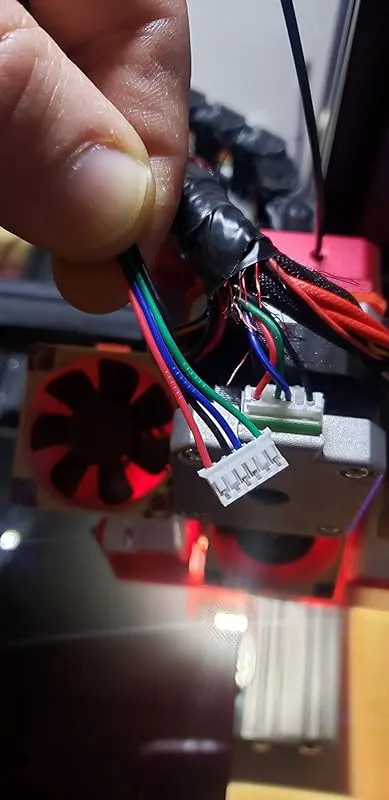

I recently purchased the 6-pack cable set and found it to be quite useful. The length of the cables is sufficient for my needs, and I appreciate the flexibility of being able to rearrange the pins if necessary.

One thing to note is that I only needed one cable, so the additional five cables in the pack were unnecessary for me. However, for those who may require multiple cables, this pack would be a great option.

I specifically used these cables to extend the wires of my 3D printer for my enclosure. Although they are not visible due to the wire loom, they have been functioning well and have served their purpose effectively.

I also came across reviews mentioning the need to swap two wires in order to make these cables compatible with printers like the Ender 3 Pro. I followed this advice and was able to get my printer up and running again without any issues. If you are comfortable with some wire swapping, I highly recommend this product.

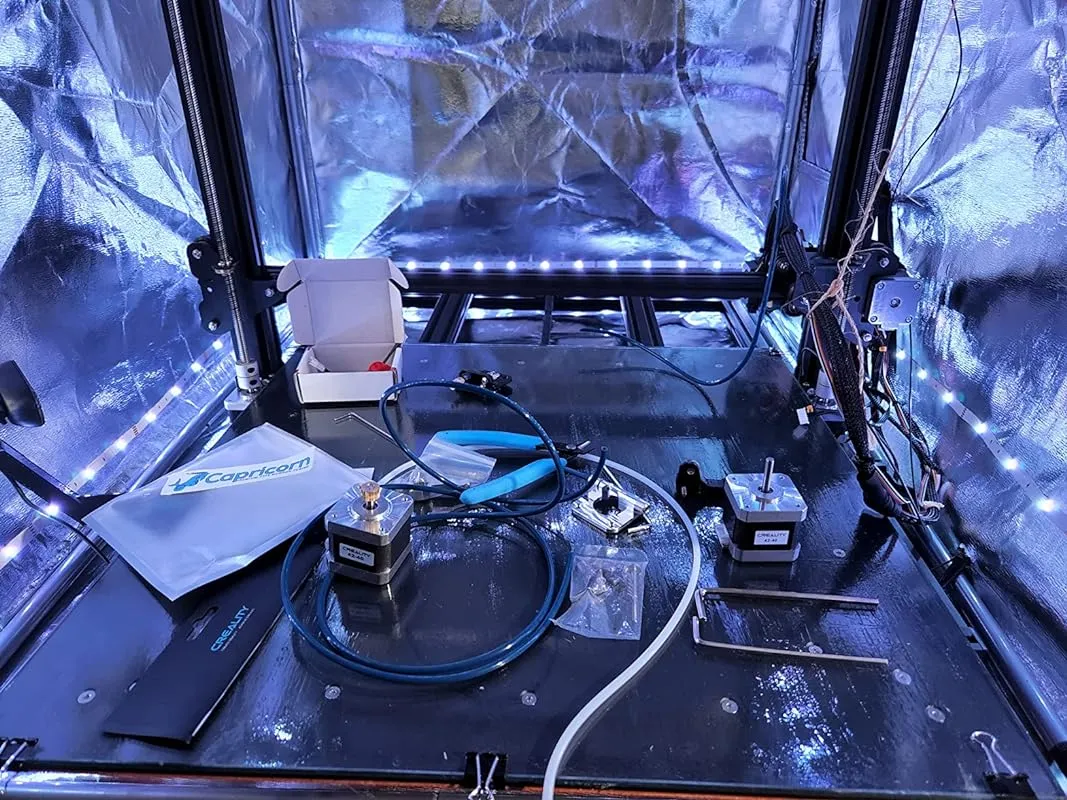

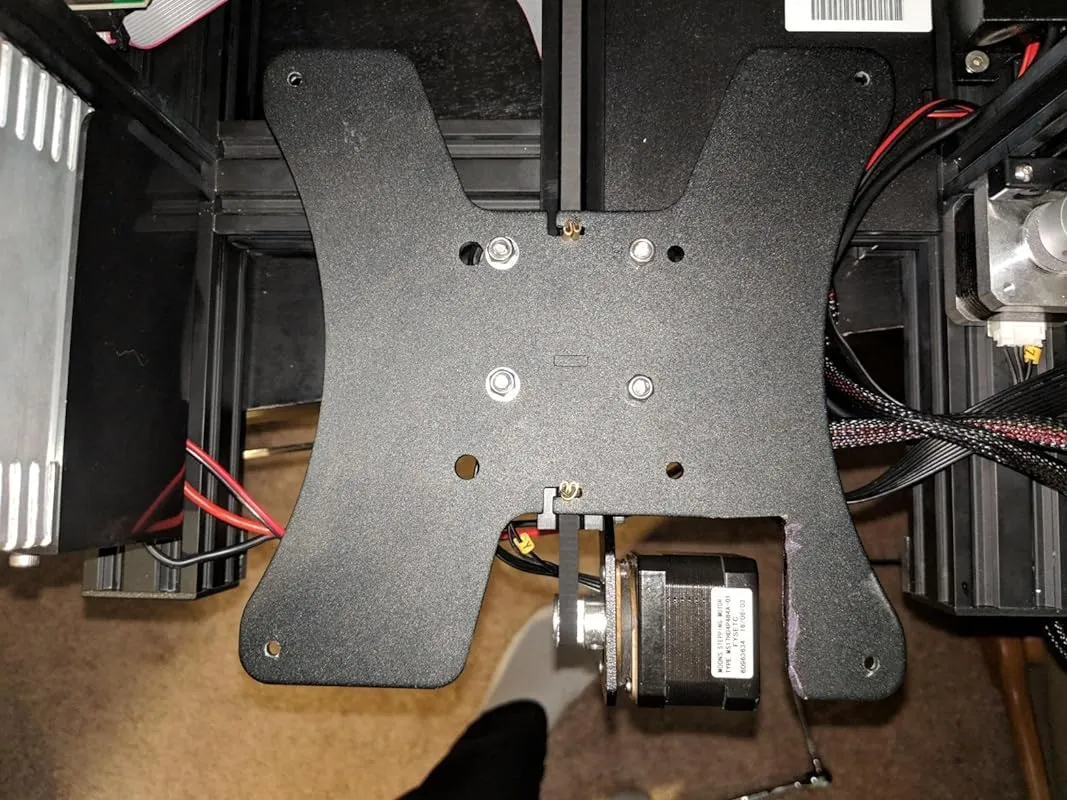

8. Ender-3 Xyz & Cr-10 Z Axis Stepper Motor

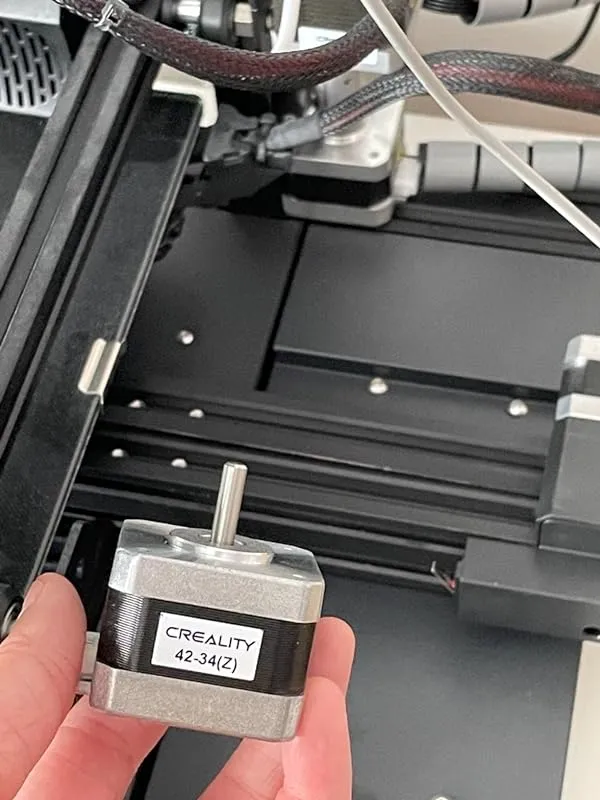

I recently purchased this stepper motor as a backup for my 3D printer, and I am quite satisfied with its performance. It is specifically designed for compatibility with the Ender 3 series printers, and I used it as a second z-axis motor for my Ender 3 v2 printer. The motor came in genuine Creality packaging, and upon comparing it to my other z-axis motor, I found them to be identical.

Installation of the motor was a breeze, and now my printer operates with the same speed and torque on both z-axes. The z-axis movement is stable and accurate, which is crucial for achieving high-quality prints. One thing that impressed me is the motor's quiet operation. There is no noticeable working noise, making for a pleasant printing experience.

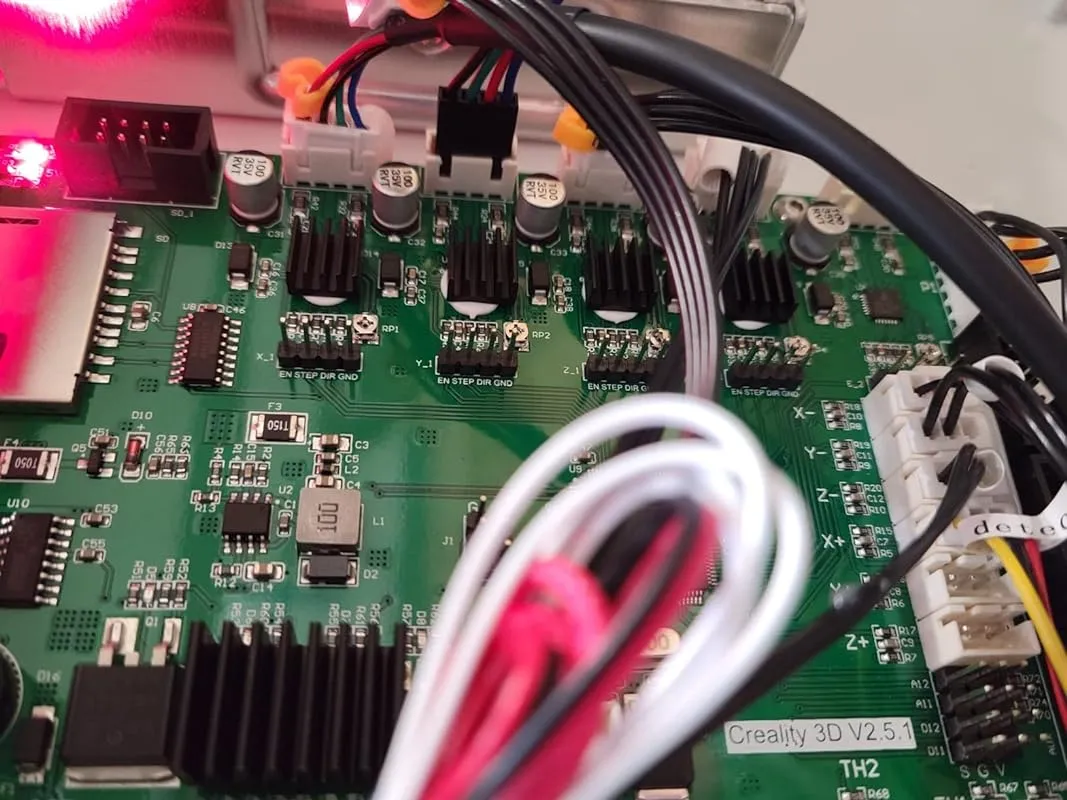

In terms of specifications, this genuine Creality motor has a 1.8-degree step angle, which is a standard option for 3D printers. With a torque of 0.4 Newton-meters and a maximum working current of 0.8 amperes per phase, the motor is powerful enough to transmit its performance to all axes. It's worth noting that the motor's quiet operation is also influenced by the stepper drivers used and the correctly adjusted working current. Older A4988 drivers may result in louder motor operation compared to newer TMC2226 or TMC2209 drivers.

FAQs

Are there any advancements or new technologies related to stepper motors that can enhance 3D printer performance or capabilities?

Yes, there have been several advancements and new technologies related to stepper motors that can enhance the performance and capabilities of 3D printers. One such advancement is the development of advanced motor control algorithms.

These algorithms enable smoother and more precise movement of the stepper motors, resulting in improved print quality and finer details in the printed objects. Additionally, there have been advancements in motor drivers, which provide higher current capabilities, allowing for faster and more accurate movements of the printer's axes.

Another technology that has been introduced is closed-loop stepper motors. Unlike traditional open-loop stepper motors, closed-loop stepper motors have built-in position feedback sensors that continuously monitor the motor's position.

This feedback allows the control system to detect and correct any missed steps, ensuring greater accuracy and reliability during printing.

Furthermore, there have been advancements in hybrid stepper motors, which combine the benefits of both stepper motors and servo motors. These hybrid motors offer the high torque and precise positioning of stepper motors, while also providing the speed and responsiveness of servo motors.

This enables faster printing speeds without compromising on print quality.

Overall, these advancements and technologies in stepper motors have significantly enhanced the performance and capabilities of 3D printers, making them more efficient, accurate, and versatile in producing high-quality prints.

Are there any recommended maintenance or lubrication practices for stepper motors used in 3D printers?

Yes, there are some recommended maintenance and lubrication practices for stepper motors used in 3D printers. Here are a few suggestions:

1. Regular Cleaning: It is important to keep the stepper motors clean and free from dust or debris. You can use a soft brush or compressed air to remove any accumulated dirt.

2. Lubrication: Some stepper motors may require lubrication, but it is essential to check the manufacturer's guidelines before applying any lubricant. If lubrication is recommended, use a high-quality, low-friction lubricant specifically designed for stepper motors.

3. Avoid Over-Lubricating: While lubrication is important, it is crucial not to over-lubricate the stepper motor. Excessive lubrication can attract more dust and debris, leading to potential issues.

4. Regular Inspection: Periodically inspect the stepper motor for any signs of wear or damage. Look for loose connections, frayed wires, or any unusual noise during operation.

5. Follow Manufacturer's Recommendations: Always refer to the manufacturer's guidelines and instructions for specific maintenance procedures and lubrication recommendations. They will provide the most accurate information for your particular stepper motor model.

Remember, proper maintenance and lubrication can help prolong the lifespan and ensure optimal performance of the stepper motors used in 3D printers.

Are there any specific considerations for using stepper motors in different types of 3D printers (e.g., Cartesian, Delta, CoreXY)?

Yes, there are specific considerations for using stepper motors in different types of 3D printers.

In Cartesian printers, which use a rectangular grid system, the stepper motors are typically used for each axis (X, Y, and Z). The motors need to have enough torque to move the print head and the build plate smoothly and accurately.

It is important to consider the weight of the components being moved and choose motors with adequate torque ratings accordingly. Additionally, the resolution and step accuracy of the stepper motors should be considered to ensure precise movement and positioning.

In Delta printers, which use three arms to move the print head, the stepper motors are typically used to control the arms' movements. The motors need to have high torque and speed capabilities to ensure smooth and precise movements of the print head.

It is important to choose motors that can handle the weight of the print head and provide enough torque for the required movements.

In CoreXY printers, which use two stepper motors to control the X and Y axes, the motors need to have enough torque and precision to move the print head smoothly in both directions. It is important to choose motors that can handle the weight of the print head and provide accurate movements for precise printing.

In general, when selecting stepper motors for any type of 3D printer, it is important to consider factors such as torque, speed, resolution, step accuracy, and the weight of the components being moved. It is also important to ensure compatibility with the printer's electronics and control system.

Can different stepper motor drivers be used with 3D printers? How do they impact performance?

Yes, different stepper motor drivers can be used with 3D printers. Stepper motor drivers are responsible for controlling the movement of the stepper motors in a 3D printer. There are various types of stepper motor drivers available in the market, such as A4988, DRV8825, and TMC2208, among others.

Different stepper motor drivers can have an impact on the performance of a 3D printer in several ways. Firstly, the maximum current output of the stepper motor driver can affect the torque and speed of the motor.

Higher current output can provide more torque, allowing the motor to move faster and handle heavier loads. Secondly, the microstepping capability of the stepper motor driver can impact the smoothness of the motor movement.

Higher microstepping resolution can result in smoother and more precise movements, which can improve the overall print quality. Lastly, the noise level of the stepper motor driver can also differ, with some drivers being quieter than others, which can be beneficial for reducing noise during printing.

When choosing a stepper motor driver for a 3D printer, it is important to consider the specific requirements of the printer and its intended applications. It is also advisable to consult the printer manufacturer or online communities to get recommendations and feedback from experienced users.

How can stepper motors be calibrated and tuned for optimal performance in a 3D printer?

Calibrating and tuning stepper motors for optimal performance in a 3D printer is a crucial step to ensure accurate and high-quality prints. Here are some steps you can follow:

1. Steps per mm: Determine the correct steps per mm value for each axis by measuring the distance traveled by the axis when commanded to move a specific distance. Adjust the steps per mm value in the firmware settings accordingly.

2. Acceleration and jerk settings: Experiment with different acceleration and jerk settings to find the optimal values that allow smooth and precise movements without causing excessive vibrations or missed steps.

Gradually increase the values while observing the print quality until the desired performance is achieved.

3. Motor current: Adjust the motor current to provide sufficient torque for smooth movement and prevent skipping steps. Ensure that the motor current is set within the acceptable range specified by the motor manufacturer.

Too low current may result in missed steps, while too high current may cause excessive heat and shorten motor lifespan.

4. Microstepping: Experiment with different microstepping settings to find the right balance between smooth movement and positional accuracy. Higher microstepping values provide smoother motion but can reduce torque and increase stepper motor noise.

5. Belt tension: Properly tension the belts in your 3D printer to minimize backlash and ensure accurate movements. Loose belts can result in imprecise prints, while overtightened belts can strain the stepper motors.

Regularly monitor and fine-tune these parameters as you gain experience and encounter different printing scenarios. Consult your 3D printer manufacturer's documentation or online communities for specific recommendations and guidelines.

How does the number of steps per revolution affect the accuracy and resolution of a 3D printer?

The number of steps per revolution in a 3D printer's stepper motor directly affects both the accuracy and resolution of the printer.

Accuracy refers to how closely the printer can reproduce the dimensions and details of a 3D model. A higher number of steps per revolution allows for finer control over the movement of the printer's extruder or print head.

With more steps, the motor can move more precisely, resulting in higher accuracy. Conversely, a lower number of steps per revolution may lead to less precise movements and reduced accuracy in the final print.

Resolution, on the other hand, refers to the level of detail that can be achieved in a print. A higher number of steps per revolution allows for smaller incremental movements of the extruder or print head, enabling finer details to be captured in the print. This leads to a higher resolution output.

Conversely, a lower number of steps per revolution may limit the level of detail that can be reproduced.

In summary, a higher number of steps per revolution in a 3D printer's stepper motor improves both accuracy and resolution, while a lower number of steps may result in reduced precision and detail.

What are the advantages of using stepper motors in 3D printers compared to other types of motors?

Stepper motors offer several advantages over other types of motors when it comes to 3D printers. Firstly, stepper motors provide precise position control, which is crucial for the intricate movements required in 3D printing.

They can move in small, incremental steps, allowing for accurate positioning and precise layering of the printed object.

Secondly, stepper motors offer excellent torque at low speeds. This is important for 3D printers as they often need to move heavy print heads or extruders. Stepper motors provide the necessary power and control to move these components smoothly and accurately.

Furthermore, stepper motors do not require additional feedback devices like encoders, reducing overall system complexity and cost. They operate in an open-loop control system, where the position is determined by the number of steps taken.

This simplicity makes stepper motors more reliable and easier to integrate into 3D printers.

Lastly, stepper motors offer holding torque, meaning they can hold their position without the need for continuous power. This feature is useful in situations where the 3D printer needs to pause or hold its position during the printing process.

In summary, the advantages of using stepper motors in 3D printers include precise position control, high torque at low speeds, simplicity, and holding torque capabilities. These qualities make stepper motors an ideal choice for driving the motion in 3D printers.

What are the common problems or issues that can arise with stepper motors in 3D printers and how can they be resolved?

There are several common problems or issues that can arise with stepper motors in 3D printers. One common issue is motor skipping or missing steps, which can result in misalignment of printed layers or inaccuracies in the final model.

This can be caused by factors such as insufficient motor current, loose belts or pulleys, or excessive motor speed. To resolve this issue, one can try increasing the motor current, tightening belts and pulleys, or reducing the motor speed to ensure smooth and accurate movement.

Another problem is motor overheating, which can occur when the motor is operated at high speeds for extended periods of time. This can lead to motor failure or reduced lifespan. To address this, one can install a heatsink or fan to dissipate heat or reduce the motor speed to prevent overheating.

Additionally, motor noise can be a common issue. This can be caused by factors such as misalignment of motor shafts, loose motor mounts, or inappropriate motor driver settings. To resolve this, one can check and adjust the motor shaft alignment, tighten motor mounts, and optimize motor driver settings for smoother and quieter operation.

In summary, common problems with stepper motors in 3D printers include motor skipping, overheating, and noise. These issues can often be resolved by adjusting motor current, tightening belts and pulleys, installing cooling mechanisms, ensuring proper motor shaft alignment, and optimizing motor driver settings.

What are the key specifications to consider when choosing stepper motors for a 3D printer?

When choosing stepper motors for a 3D printer, there are several key specifications to consider. Firstly, you need to look at the torque rating of the motor. This determines the motor's ability to move the printer's axis effectively.

Higher torque motors are generally preferred as they provide better control and precision.

Next, consider the motor's step angle. This refers to the angle at which the motor moves per step. Lower step angles, such as 1.8 degrees, are commonly used in 3D printers as they provide smoother and more accurate movements.

Another important specification is the holding torque of the motor. This measures the motor's ability to hold its position when power is not applied. Higher holding torque ensures that the printer's axis remains stable during pauses or power loss.

Additionally, check the motor's voltage and current rating. These should match the requirements of your printer's electronics. Running the stepper motor at its recommended voltage and current levels ensures optimal performance and longevity.

Lastly, consider the physical dimensions of the motor. It should fit within the available space in your printer's design without any constraints.

Overall, choosing stepper motors for a 3D printer requires considering torque, step angle, holding torque, voltage, current rating, and physical dimensions to ensure smooth and precise movements for your printer.

What is a stepper motor and how does it work in a 3D printer?

A stepper motor is a type of electric motor commonly used in 3D printers. It is designed to move in precise increments or steps, hence the name "stepper" motor. Unlike conventional motors that rotate continuously, a stepper motor rotates in discrete steps.

In a 3D printer, stepper motors play a vital role in controlling the movement of the printer's various components, such as the print head, build plate, and filament feeder. These motors are typically connected to lead screws or belts, which translate the rotary motion of the motor into linear motion.

To achieve precise positioning, a stepper motor relies on a series of electromagnetic coils. These coils are energized in a specific sequence, creating magnetic fields that attract the motor's rotor, causing it to move to the next step.

By controlling the timing and sequence of these coil energizations, the printer's control system can accurately position the various components.

Stepper motors offer several advantages for 3D printers, including high precision, excellent control, and the ability to hold a position without the need for external holding mechanisms. They are an integral part of the printer's overall functionality, enabling precise and repeatable movements necessary for producing intricate and detailed prints.